Your Partner in Quality & Compliance

Getting your products certified in India can be complicated. At Omega QMS, we make it simple.

We're one of India's top firms for helping businesses meet all the necessary standards and government regulations. We have a long history of success across many industries, and we specialize in BIS certification.

Our team handles the entire process for you. We'll get your products registered and licensed, making sure you're fully compliant with Indian Standards and Quality Control Orders (QCOs). We work with a huge range of products, including electronics, IT, footwear, furniture, steel, and chemicals.

With our unparalleled expertise and commitment to excellence, we empower businesses to achieve conformity and maintain a competitive edge in the global marketplace.

What We Do:

- BIS Certification (FMCS, CRS, Scheme-X, Hallmarking, etc.): We manage everything you need for BIS certification. This includes new registrations, renewals, and any changes for both Indian and international manufacturers.

- Regulatory Approvals: Facilitation for BEE, TEC, and other government-mandated approvals across product categories.

- Policy and QCO Advisory: Specialized support in representation, extension requests, and exemption advocacy with Ministries, BIS, and DPIIT. We actively engage with policymakers and industry chambers to promote ease of compliance and rationalization of QCOs across sectors.

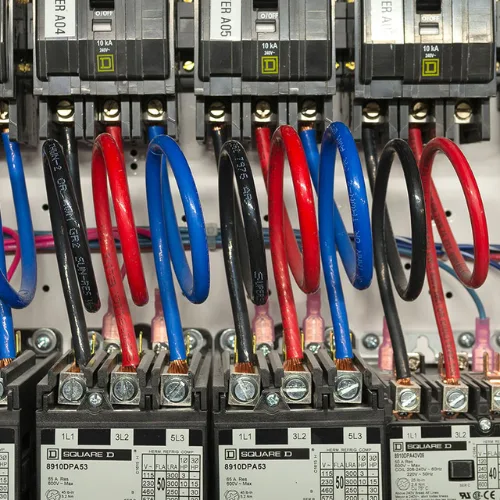

- Testing Infrastructure & Laboratory Setup: We design, build, and install modern lab testing equipment that meets Indian and international standards. We can also help you set up your own lab that's officially recognized by BIS and NABL.

Why Work With Us?

Our team is made up of former BIS officers and technical experts who know this industry inside and out. With decades of hands-on experience, we know how to handle everything from product certification to working with the government.

We take care of the entire process, so you don't have to.