BIS SCHEME-X CERTIFICATION (OTR)

BIS SCHEME-X CERTIFICATION (OTR)

ABOUT SCHEME-X (Omnibus Technical Regulation)

Scheme-X (Omnibus Technical Regulation) is a specialized conformity assessment scheme designed for machineries that require specific safety and risk reduction conformances. It allows manufacturers to obtain a BIS licence or certificate of conformity to use the BIS Standard Mark on their machineries.

What is Technical File..?

Technical file comprises documentation covering design, manufacture and operation of machineries necessary for demonstration of compliance of conformity. Technical file must be submitted with the application.

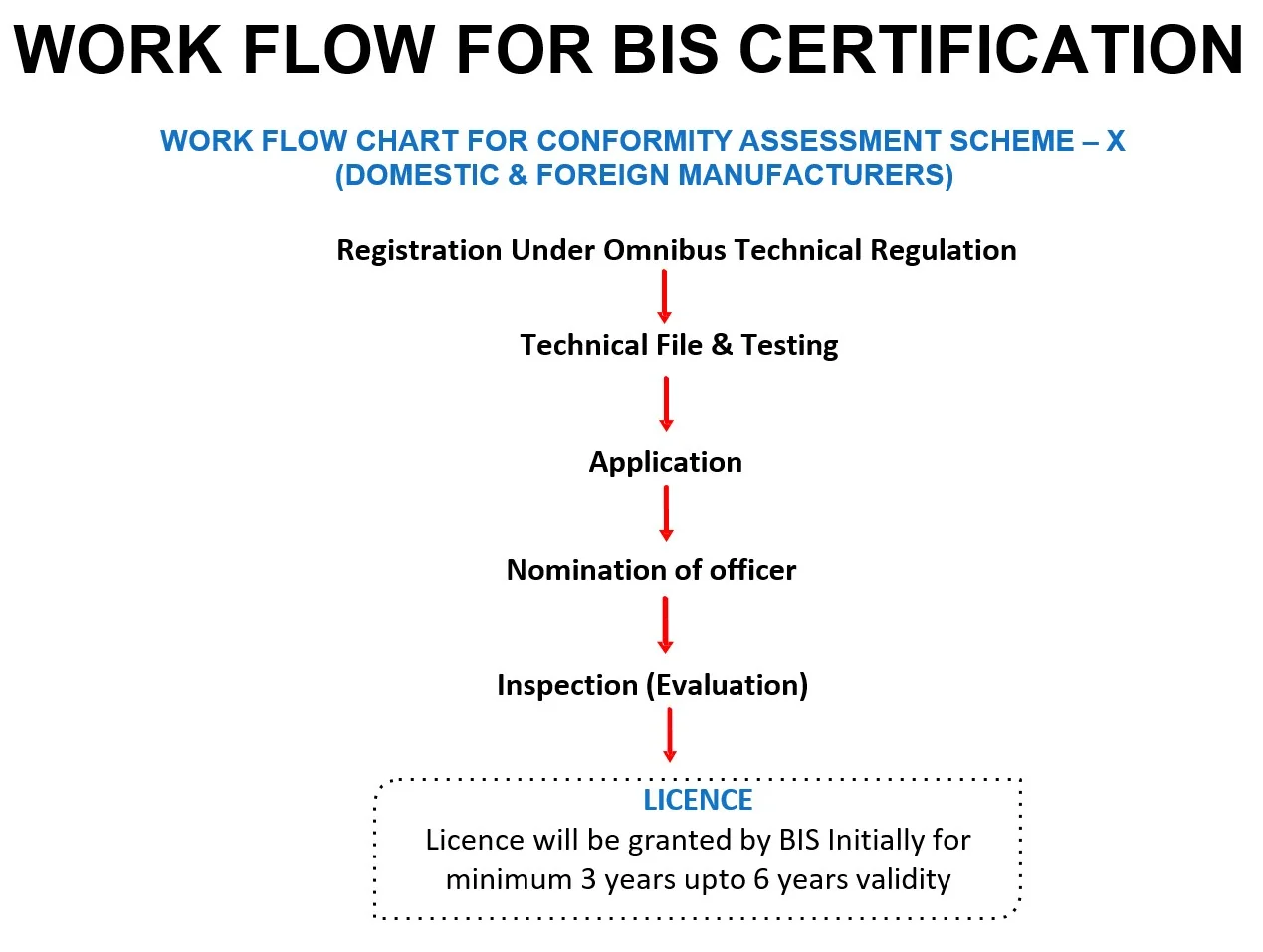

MAJOR STEPS IN OBTAINING SCHEME X CERTIFICATION UNDER OTR

- Registration Under Omnibus Technical Regulation on BIS Manak Online Portal

- Preparation of Technical file, Product details and Test Reports for:

- Type A Standard (IS 16819:2018/ISO 12100:2010)

- Applicable Type B and/or Type C Standards

- Submission of Application form, Supporting Documents and Application Fee to BIS

- Review of Technical file & Application by BIS through Desk Audit and Assessment

- Nomination of BIS Inspection Team of 2 Officers for Manufacturing Site Audit

- Site Audit / Assessment Inspection by BIS Inspection Team

- Grant of Licence by BIS if Manufacturing Site Audit Results are Satisfactory

- Renewal of Scheme X (OTR) License after 3-6 Years of Validity