Mandatory Testing and Certification of Telecom Equipments by TEC

Toys amuse children and keep them engaged and entertained for long hours. It is, therefore, essential that we are vigilant and purchase only safe toys. Last year alone, more than 100,000 children under the age of 4 were cared for toy-related accidents in hospitals, according to the National Safe Kids Program. The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued the Toys (Quality Control) Order, 2020 on 25 Feb. 2020, which makes it mandatory that w.e.f. 1 September 2020, all the toys being manufactured, stored, transported, and sold in India are certified under Scheme 1 of Schedule 2 of the Bureau of Indian Standards (Conformity Assessment) Regulations, 2018.

This Order also equally applies to all toys being imported into India, and that the Foreign Manufacturer must also obtain a valid certification from BIS, as is mandatory for all the manufacturers of toys in India.

The procedure of BIS Certification for Toys

BIS has already notified its procedure for certification of toys and this involves on-site verification of manufacturer’s competence to manufacture and test toys as per the relevant Indian Standards, IS 9873 Series (Part 1, 2, 3, 4, 7 & 9) and IS 15644. It also mandates that manufacturer shall be required to install in-house test facilities for testing of toys as per IS 9873 (Pt 1), IS 9873 (Pt 2) and IS 9873 (Pt 4). For the remaining Indian Standards, that is, IS 9873 (Pt 3), IS 9873 (Pt 7), IS 9873 (Pt 9) and IS 15644, manufacturer shall be required to have a working arrangement for testing of their samples at one of the BIS recognized laboratories.

Requirement for BIS Certification of Toys

The manufacturer is required to apply online to BIS along with requisite and documents. If found in order, BIS will record the application and arrange for on-site verification (at manufacturer’s factory) of the manufacturer’s competence to manufacture and test toys as per the relevant Indian Standards through one of its officers. During the audit, representative sample(s) of the toys being manufactured shall be drawn for independent testing in one of the BIS recognized labs. If the results of on-site verification and laboratory testing are found to be satisfactory, BIS will grant licence to the manufacturer.

Consultancy Services for BIS Certification of Toys

Omega QMS is India’s premier and leading Consulting Organization over the last two decades. Omega QMS is already empanelled with The Toys Association of India (TAI) and The Association of Indian Toys Manufacturers (TAITMA) for providing Consultancy Services for certification of toys to the members of these Associations, besides being engaged by leading importers and manufacturers of toys across the globe. The certification is done by the Lab Testing equipments for Toys.

Our Services

Omega QMS has a carved niche for its services in the realm of regulatory compliance and many of the Fortune 500 Companies of the world count among its clients. This has been possible through consistently effective, efficient, and reliable services. Omega QMS takes pride in maintaining the confidentiality of client information and IPR, and believes in ethical conduct. It is India’s leading Consultancy Services provider to the industry across the entire gamut of India’s economic activity, including inter alia, Product Certification for domestic and foreign manufacturers, Hallmarking of precious metals, Compulsory Registration of electronic & IT goods, BEE registrations, TEC and WPC approvals, etc.

Omega QMS is, therefore, your “one-stop-solution” for all your certification needs

BIS certification mandatory for toys

According to the Toys (Quality Control) Order all toys and material for children below 14 years are required to be certified by the India’s national standards i.e., BIS body. Absence of which shall result in criminal liability, including imprisonment and huge fines.

Do we need to submit separate applications for each standard mentioned in the Toys (Quality Control) Order, 2020?

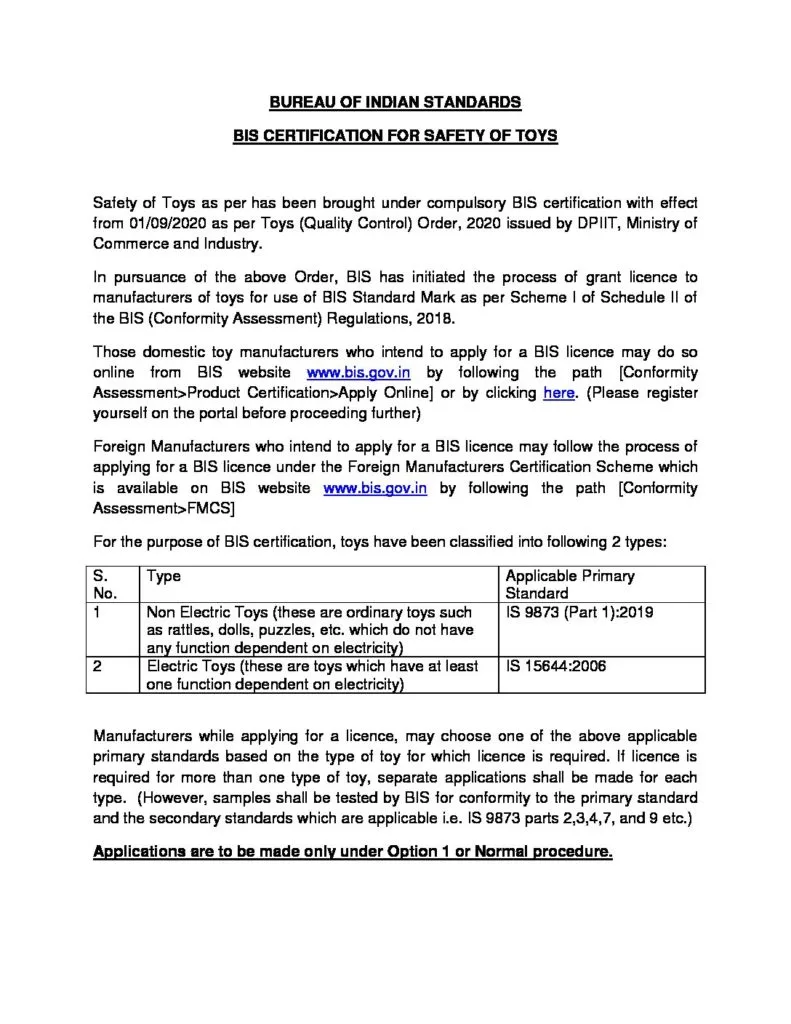

Electric Toys (these are toys which have at least one function dependent on electricity as mentioned in the scope of IS 15644) and Non-Electric Toys (these are ordinary toys such as rattles, dolls, puzzles, etc. which do not have any function dependent on electricity).

Manufacturers may select one of the above applicable primary standards when applying for a licence based on the type of toy for which a licence is required. If a licence is needed for more than one type of toy (for example, non-electric and electric), each type must be applied for separately.

Frequently Asked Questions

Is BIS certification mandatory for toys in India?

Yes, BIS certification is mandatory for all toys in India. The Toys (Quality Control) Order, 2020, issued by the DPIIT, Ministry of Commerce & Industry, makes it compulsory that from 1 September 2020, all toys being manufactured, stored, transported, and sold in India must be certified under Scheme 1 of Schedule 2 of the Bureau of Indian Standards (Conformity Assessment) Regulations, 2018.

This requirement applies equally to domestic manufacturers and imported toys. Foreign manufacturers must also obtain valid BIS certification before their products can be sold in India. Absence of BIS certification can result in criminal liability, including imprisonment and substantial fines.

Which Indian Standards apply to toy certification?

BIS toy certification requires compliance with the IS 9873 Series and IS 15644 standards. Specifically, manufacturers must meet:

- IS 9873 Part 1: Mechanical and physical properties

- IS 9873 Part 2: Flammability requirements

- IS 9873 Part 3: Migration of certain elements (chemical safety)

- IS 9873 Part 4: Swings, slides and similar activity toys

- IS 9873 Part 7: Finger paints

- IS 9873 Part 9: Organic chemical compounds

- IS 15644: Safety requirements for electric toys

Manufacturers must install in-house testing facilities for Parts 1, 2, and 4, while testing for Parts 3, 7, 9, and IS 15644 can be conducted at BIS-recognized laboratories through a working arrangement.

Do I need separate BIS applications for electric and non-electric toys?

Yes, separate applications are required for electric and non-electric toys.

Electric Toys:

These are toys which have at least one function dependent on electricity (covered under IS 15644). Examples include battery-operated toys, remote-controlled cars, and electronic learning devices.

Non-Electric Toys:

These are ordinary toys such as rattles, dolls, puzzles, board games, and plastic figures that do not have any function dependent on electricity (covered under IS 9873 series).

Manufacturers must select the applicable primary standard when applying for a BIS licence based on the type of toy. If you manufacture both electric and non-electric toys, you must submit separate applications for each category.

What is the BIS certification process for toys?

The BIS certification process for toys involves several key steps:

- Online Application: Submit an application to BIS online along with all required documents and information about your manufacturing facility.

- Application Review: BIS reviews the application and supporting documents. If everything is in order, the application is recorded and accepted.

- On-Site Verification: BIS arranges for an on-site factory audit through one of its officers to verify your manufacturing competence and testing capabilities according to relevant Indian Standards.

- Sample Testing: During the audit, representative samples of toys are drawn and sent to a BIS-recognized laboratory for independent testing against applicable standards.

- Licence Grant: If both the on-site verification and laboratory test results are satisfactory, BIS grants the manufacturer a licence to use the ISI Mark on certified toys.

Omega QMS provides comprehensive consultancy services throughout the BIS certification process, helping manufacturers establish in-house testing facilities, prepare documentation, and successfully navigate the audit and certification process.