BIS Certification of PP/HDPE Woven Sacks

A certified product will always get preference over a product without any quality certification. So manufacturers looking for BIS certification for PP/HDPE woven sacks, you are going to be customers' prime choice. These bags are best suitable for packaging purposes and the market is immensely growing worldwide due to the usability benefits of the PP/HDPE woven bags.

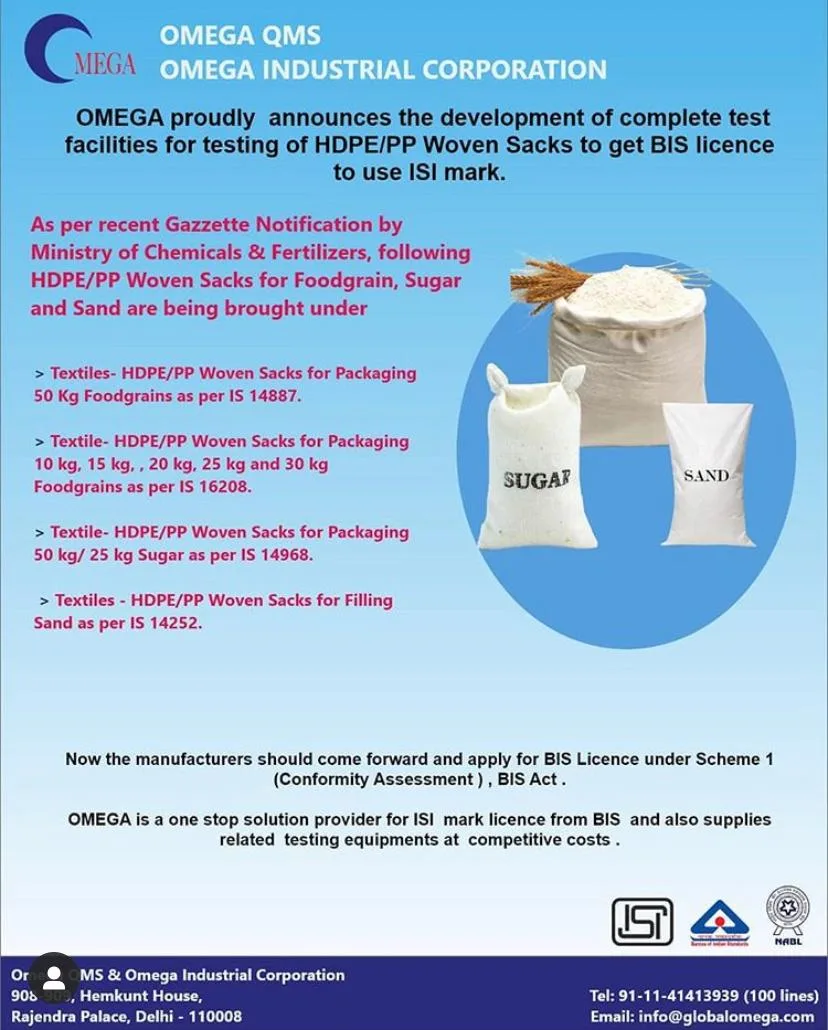

Omega QMS is a recognized consultancy firm serving from the last 4 decades helping manufacturers get their products certified. Besides being a top ISI mark consultancy, we are also a renowned manufacturer, service provider, supplier, exporter of testing equipment. Our services can be availed at PAN India level.

Benefits of getting BIS license for PP woven bags

In the past few years, the use of Polypropylene/High-density Polyethylene woven bags has increased hugely and the market has reached across a volume of 30 million tons. The demand and usage of the product have witnessed a noticeable hike, all because of PP/HDPE usage benefits. These bags have become the choice of almost many enterprises that are dealing in the sale of sugar, mills, grains, and other materials that need strong packaging. Some of the benefits of PP and HDPE bags include

Tough and strong packaging.

Flexible and durable

Reusable product

Bags don't wear and tear.

Doesn't degrade in a wet state.

robust option over multi-wallpaper bags.

But these benefits can be best enjoyed when the product is not compromising on quality aspects. Bureau of Indian Standards is the biggest body under which ISI certifications are accorded.

ISI mark represents the quality and therefore leading to more long term relationships with the customers. Getting your PP/HDPE woven bags ISI certified will increase the value of your product and brand as well. Besides catalyzing your lead generation process, testifying your products beforehand will also ensure the safety of customers.

Why Choose Omega QMS for BIS certification for PP/HDPE woven bags?

BIS certification is focused on providing a third-party guarantee of quality, safety, and reliability of products to the customer. Testifying your products will not only secure you as a manufacturer, but customers will also get a quality certified product. Moreover, this is the most effective business strategy to gain customer trust, build long term relationships, and enjoy lucrative profits.

Omega QMS is attached to the word quality since 2001 and has recognized as the best quality consultancy firm for BIS license, ISI certification, and other quality management services. In addition to providing assistance to different enterprises in getting BIS license, products testified, completing documentation, Omega QMS is also loved for being the best manufacturer, service provider, supplier, exporter of quality testing equipment.

Quality is the highest standard we always focus on. With a dedicated team of professionals, Omega QMS is best known for quality assurance, quality control, and quality management services. We are catering to a list of more than 800 national and international clients working under governmental directions. Therefore you can feel free to connect for getting BIS certification for PP/HDPE woven bags or getting quality standard testing equipment.