BIS CERTIFICATION OF SAFE, SAFE DEPOSIT LOCKER CABINETS AND KEY LOCKS FOR SECURITY EQUIPMENT AS PER IS 550 (PART 1):2022, 5244:2020 AND IS 17566:2021

INTRODUCTION

The security of personal belongings and valuables is a paramount concern for individuals and businesses alike. In ensuring the safety of these items, the use of safe deposit locker cabinets and key locks meeting stringent standards is imperative. The Bureau of Indian Standards (BIS) plays a pivotal role in certifying such security equipment, ensuring adherence to national standards such as IS 550 (Part 1) for safe deposit locker cabinets, IS 5244 for key locks, and IS 17566 for security equipment.

INDIAN STANDARDS

IS 550 (PART 1):2022 SAFES

IS 5244:2020 SAFE DEPOSIT LOCKER CABINETS

IS 17566:2021 KEY LOCKS FOR SECURITY EQUIPMENT

This standard specifies the general requirements and performance criteria for key locks for security equipment like but not limited to safes, strong room doors, safe deposit locker cabinets, etc. Requirements of lever lock, two key lock and cylindrical locks have been prescribed. The lock shall be constructed so that it will operate only when the intended key or keys are used. The product shall be constructed for installation in a position or location such that it does not reduce the burglary/fire resistant qualities of the security product on which it is being used. For lock with sliding bolt, throw of the bolt shall be minimum 7 mm from unlocked to locked position. For locks with rotational bolt movement, rotation of the bolt shall be minimum 90 degrees from unlocked to locked position. For Lever Type Lock Minimum thickness of lever shall not be less than 1.2 mm nominal. False (dummy) levers shall not be used. Difference between gate of the lever and thickness of bolt stump in the direction perpendicular to bolt movement shall not be more than 1.0 mm. The lock should not open by using a key having only one key cut different from the actual Key of that lock. Similarly, lock should not open with one depth difference of the design in lever, tumblers, or pin. All parts of the lock shall be constructed of brass, bronze, zinc base alloy, stainless steel or corrosion resistant materials or steel with protective finish. All parts of the lock shall be able to comply with the salt spray corrosion test. Endurance Test, Bolt Forcing Test, Salt Spray Corrosion Test, Key Strength are some of the performance tests specified for locks.

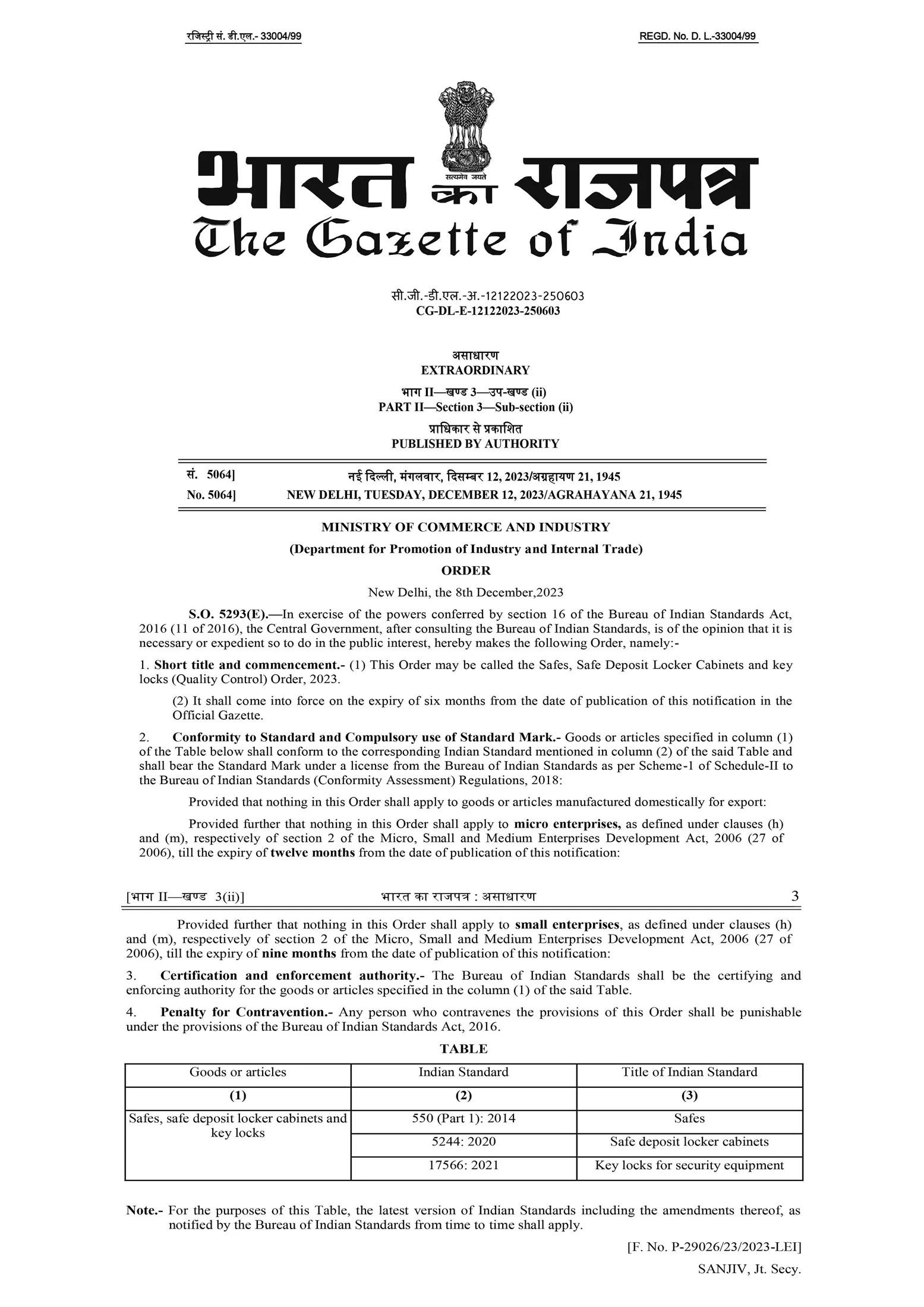

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 08 DECEMBER 2023 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for all fasteners to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence. In short, it has become obligatory for all the manufacturers of fasteners, wherein in India or overseas, to immediately apply for BIS licence and obtain a valid BIS certification licence before that the last date of implementation of the order, i.e., 07 June 2024.

BIS certification serves as a mark of quality and compliance, assuring consumers and businesses alike of the reliability and safety of the certified products. Under these standards, safe deposit locker cabinets are rigorously tested for durability, resistance to tampering, and fire protection, while key locks are evaluated for strength, precision, and resistance to unauthorized access. Manufacturers seeking BIS certification must undergo thorough testing and inspection processes to ensure their products meet these exacting standards.

OMEGA QMS PVT. LTD. AT YOUR DOORSTEP

Omega QMS Pvt. Ltd. plays a crucial role in facilitating the BIS certification process for manufacturers of security equipment. As a leading regulatory compliance consultancy firm, Omega QMS provides comprehensive support to manufacturers in navigating the complexities of certification requirements. Their expertise encompasses documentation assistance, quality audits, testing coordination, and compliance management, streamlining the certification journey for manufacturers and ensuring efficient adherence to BIS standards. With Omega QMS’s guidance, manufacturers can expedite the certification process, enhance product credibility, and gain a competitive edge in the market.

CONCLUSION

In conclusion, BIS certification serves as a hallmark of quality and safety for safe deposit locker cabinets, key locks, and other security equipment. Adherence to standards such as IS 550 (Part 1), IS 5244, and IS 17566 ensures that these products meet stringent criteria for reliability, durability, and resistance to unauthorized access. With the support of organizations like Omega QMS Pvt. Ltd., manufacturers can navigate the certification process with ease, bolstering consumer confidence and advancing the integrity of security equipment in the market.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India