BIS CERTIFICATION FOR VENEERED PARTICLE BOARDS AS PER IS 3097:2006

INTRODUCTION

Veneered particle boards serve as essential components in various construction and furniture applications due to their versatility and cost-effectiveness. However, ensuring their quality and performance requires adherence to industry standards. One such standard is IS 3097, which provides comprehensive guidelines for the manufacturing, testing, and grading of veneered particle boards. In this article, we’ll delve into the key aspects of this standard to understand its significance and implications for manufacturers and consumers alike and also role of Omega QMS Pvt. Ltd. in obtaining BIS Certification for manufacturers.

IS 3097:2006 VENEERED PARTICLE BOARDS

A crucial aspect of IS 3097 is the testing procedures and acceptance criteria for veneered particle boards. These tests include density determination, moisture content analysis, water absorption, water resistance, swelling, adhesion of plies, modulus of rupture, and deflection under sustained load. Compliance with these tests ensures the quality, durability, and performance of the boards.

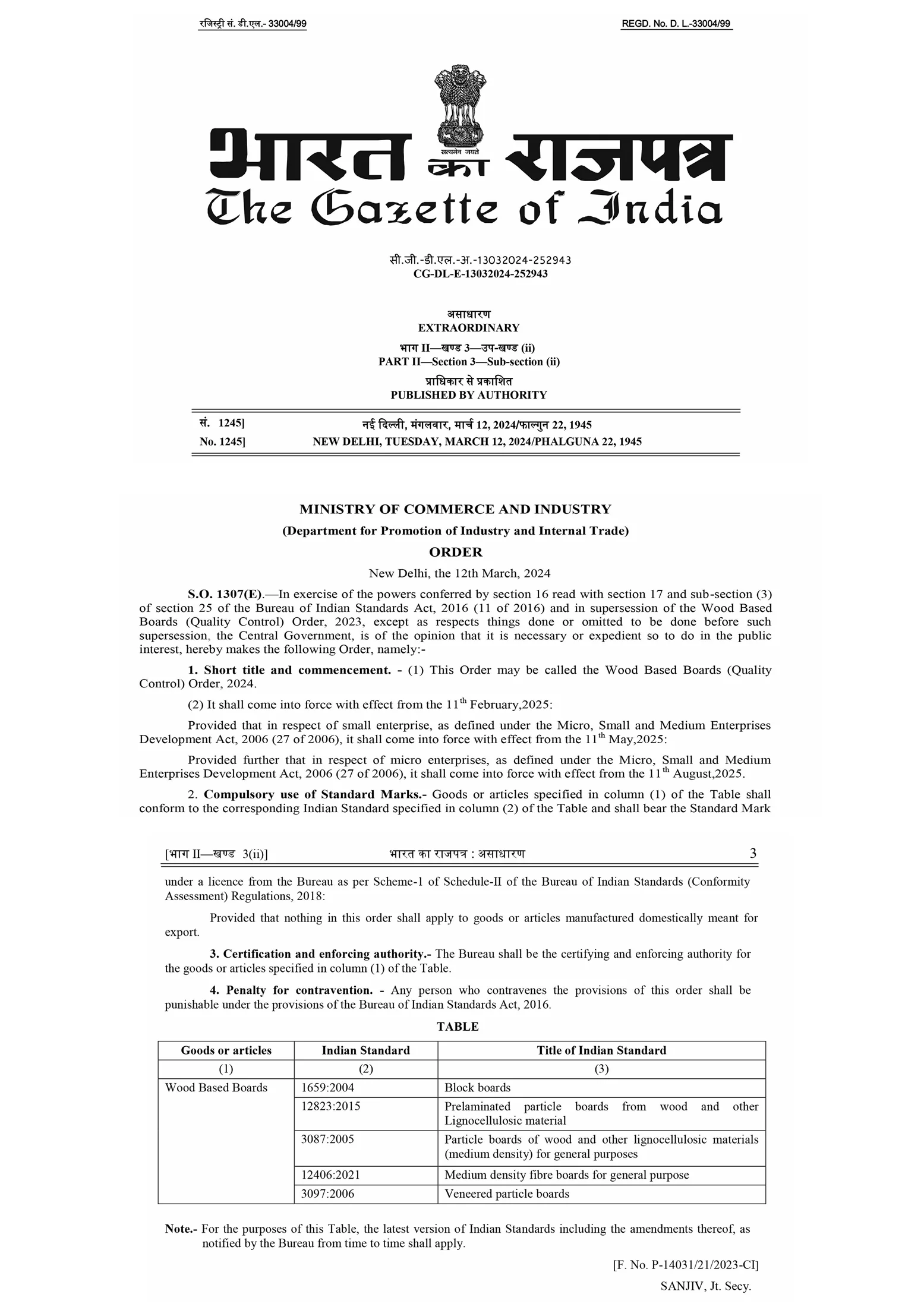

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 12 MARCH 2024 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for block boards as mentioned above to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark (ISI Mark ) of the Bureau of Indian Standards under a valid BIS license. In short, it has become obligatory for all the manufacturers of block boards, whether in India or overseas, to immediately apply for BIS license and obtain a valid BIS certification license before that the last date of implementation of the order, i.e., 11 February 2025.

BIS CERTIFICATION SCHEME FOR VENEERED PARTICLE BOARDS

The BIS certification scheme aims to ensure that products meet specified standards for quality, safety, and performance. Manufacturers seeking BIS certification for veneered particle boards must adhere to the requirements outlined in IS 3097. Compliance with this standard is verified through rigorous testing and inspection processes conducted by BIS-approved laboratories.

OMEGA QMS PVT. LTD. – PARTNERING FOR SUCCESS

In the pursuit of BIS certification and maintaining high product quality, Omega QMS Pvt. Ltd. is an invaluable partner for manufacturers. With a global presence and a track record of successful collaborations, Omega QMS provides services to streamline the certification process, ensuring compliance with industry standards, including BIS certification of veneered particle boards as per IS 3097.

Expert Guidance: Omega brings together seasoned experts with in-depth knowledge of regulatory requirements, guiding manufacturers through the certification process efficiently.

Testing and Validation: Assisting in planning and executing necessary tests and validations required for BIS certification of veneered particle boards as per IS 3097.

Documentation and Compliance: Assisting in creating comprehensive and accurate documentation aligning with BIS requirements.

Inspection Support: Preparing manufacturers for BIS inspection, ensuring preparedness and addressing any issues that may arise, with a specific focus on BIS certification of veneered particle boards as per IS 3097.

Customized Approach: Tailoring services to fit the specific needs, challenges, and goals of individual manufacturers.

Global Experience: Leveraging a presence in over 40 countries to offer insights into varying regulatory environments and industry practices, emphasizing the international importance of BIS certification of veneered particle boards as per IS 3097.

Omega QMS Pvt. Ltd. functions as a strategic partner for manufacturers seeking BIS Certification, providing a competitive edge while upholding the highest standards of product quality and consumer satisfaction.

CONCLUSION

IS 3097 plays a vital role in regulating the quality and performance of veneered particle boards in the construction and furniture industries. By following its guidelines for material selection, manufacturing processes, and testing procedures, manufacturers can produce reliable products, while consumers can make informed decisions based on standardized quality parameters. Ultimately, adherence to this standard promotes trust, reliability, and sustainability across the veneered particle board industry.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India