BIS CERTIFICATION FOR STEEL AND STEEL PRODUCTS

INTRODUCTION

In the realm of steel production and manufacturing, stringent adherence to quality standards is paramount. The Bureau of Indian Standards (BIS) plays a crucial role in ensuring the quality and reliability of steel and steel products in India and beyond through its comprehensive certification process. With the Ministry of Steel, Government of India, issuing Quality Control Orders to enforce compliance with relevant Indian standards, navigating this landscape requires expertise and guidance. This is where Omega QMS Pvt. Ltd. emerges as an undisputed leader, offering technical assistance to manufacturers worldwide in obtaining and maintaining BIS certification. Let’s delve deeper into the intricacies of BIS certification for steel and steel products, exploring the standards, requirements, certification scheme, and the pivotal role played by Omega QMS Pvt. Ltd.

INDIAN STANDARDS ON STEEL AND STEEL PRODUCTS

The range of Indian standards available for steel and steel products is extensive, covering a wide spectrum of materials, processes, and applications within the steel industry. These standards encompass specifications for steel ingots, billets, plates, sheets, wires, rods, structural steels, steel ropes, and more—all of which are integral components of the BIS certification process. They define parameters such as chemical composition, mechanical properties, dimensions, tolerances, and testing methods, ensuring uniformity, reliability, and safety across the production and utilization of steel. Additionally, Indian standards address specific requirements for diverse applications, including construction, automotive, infrastructure, manufacturing, and engineering, catering to the varied needs of industries and sectors reliant on steel materials. By providing comprehensive guidelines and benchmarks, these standards facilitate quality assurance, interoperability, and compliance with regulatory mandates under BIS certification, thereby enhancing the overall integrity and performance of steel and steel products in the market.

| Sl. No | Indian Standard | Title |

|---|---|---|

| 1 | IS 1785 (Part 1): 1983 | Plain Hard-drawn steel wire for pre – stressed concreate: Part 1 Cold Drawn Stress – relieved wire |

| 2 | IS 1785 (Part 2): 1983 | Plain Hard-drawn steel wire for pre – stressed concreate Part 2 : As drawn wire |

| 3 | IS 6003:2010 | Indented wire for pre-stressed concrete |

| 4 | IS 6006:2014 | Uncoated stress relieved strand for pre – stressed concrete |

| 5 | IS 13620:1993 | Fusion bonded epoxy coated reinforcing bars |

| 6 | IS 14268:1995 | Uncoated stress relieved low relaxation seven –ply Stand for pre – stressed concrete. |

| 7 | IS 277: 2003 | Galvanized steel sheets (plain and corrugated). |

| 8 | IS 2002:2009 | Steel plates for pressure vessels for intermediate and High temperature service including boilers. |

| 9 | IS 2041:2009 | Steel plates for pressure vessels used at moderate and Low temperature |

| 10 | IS 2830:2012 | Carbon steel cast billet ingots, billets, blooms and slabs For rerolling into steel for general structural purpose |

| 11 | IS 1786:2008 | High strength deformed steel bars and wires for concrete reinforcement |

| 12 | IS 648:2008 | Cold rolled non-oriented electrical steel sheets and strip-fully processed type (CRNO) |

| 13 | IS 3024:2015 | Grain oriented electrical steel sheet & strip (CRGO) |

| 14 | IS 15391:2003 | Oriented electrical steel sheet and strip – semi- processed type – specification. |

| 15 | IS 2062:2011 | Hot rolled medium and high tensile structural steel |

| 16 | IS 432:Part 1:1982 | Mild steel and medium tensile steel bars and Hard-drawn steel wire for concrete reinforcement: Part 1 mild steel and medium tensile steel bars |

| 17 | IS 423:Part 2 :1982 | Mild steel and medium tensile steel bars and hard-drawn steel wire for concrete reinforcement: Part 2 hard –drawn steel wire |

| 18 | IS 513 (Part – 1): 2016 | Cold reduced carbon steel sheets and strips Part 1 cold forming and drawing purpose |

| 19 | IS 513 (Part – 2): 2016 | Cold reduced carbon steel sheets and strips Part 2 high tensile and multi – phase steel |

| 20 | IS 1079:2017 | Hot rolled carbon steel sheet, plate and strip – specification |

| 21 | IS 1875:1992 | Carbon steel billets, blooms, slabs and bars for forgings. |

| 22 | IS 2879:1998 | Mild steel for metal arc welding electrodes. |

| 23 | IS 3502:2009 | Steel chequered plates |

| 24 | IS 5872:1990 | Cold rolled steel strips (box strappings) |

| 25 | IS 5986:2017 | Hot rolled steel sheet, plate and strip for foaming and flaming purposes – specification |

| 26 | IS 6240:2008 | Hot rolled steel plate (up to 6 mm) sheet and strip for the manufacture of low pressure liquefiable gas cylinders |

| 27 | IS 7283:1992 | Hot rolled bars for production of bright bars and machined Parts for engineering applications. |

| 28 | IS 7887:1992 | Mild steel wire rods for general engineering purposes |

| 29 | IS 10748:2004 | Hot rolled steel strips for welded tubes and pipes. |

| 30 | IS 11513:2017 | Hot rolled carbon steel strip for cold rolling purposes – specification |

| 31 | IS 15647:2006 | Hot rolled steel narrow width strip for welded tubes and pipes |

| 32 | IS 7904:2017 | High carbon steel wire rods – specification |

| 33 | IS 14246:2013 | Continuously pre – pained galvanized steel sheets and coils |

| 34 | IS 15965:2012 | Pre – pained aluminium zinc alloy metallic coated steel strip and sheet (plain) |

| 35 | IS 280:2006 | Mild steel wire for general engineering purposes. |

| 36 | IS 1835:1976 | Round steel wire for ropes |

| 37 | IS 3975:1999 | Low carbon galvanized steel wires and tapes for armouring of cables |

| 38 | IS 4368:1967 | Alloy steel billets, blooms and slabs for forging for general engineering purposes. |

| 39 | IS 4454 (Part 1): 2001 | Steel wire for mechanical springs Part-1 cold drawn unalloyed steel wire. |

| 40 | IS 4454 (Part 2): 2001 | Steel wire for mechanical springs Part-2 oil hardened and tempered steel wire. |

| 41 | IS 4824:2006 | Bead wires for tyres |

| 42 | IS 11169(Part 1): 1984 | Steels for cold heading/cold extrusion application Part-1 wrought carbon and low alloy steels |

| 43 | IS 11587:1986 | Structural weather resistant steel. |

| 44 | IS 15103:2002 | Fire resistance steel – specification |

| 45 | IS 15914:2011 | High tensile strength flat rolled steel plate (up to 6 mm),sheet and strip for the manufacture of welded gas cylinder. |

| 46 | IS 15961:2012 | Hot dip aluminum – zinc alloy metallic coated steel strip and sheet (plain) |

| 47 | IS 15962:2012 | Structural steel for building for structures with improved seismic resistance |

| 48 | IS 6527:1995 | Stainless steel wire rod |

| 49 | IS 6528:1995 | Stainless steel wires |

| 50 | IS 6603:2001 | Stainless steel bars and flats |

| 51 | IS 5522:2014 | Stainless steel sheets and strips for utensils – specification |

| 52 | IS 6911:2017 | Stainless steel plate, sheet and strip – specification |

| 53 | IS 15997:2012 | Low nickel austenitic stainless steel sheet and strip for utensils and kitchen applications – specification |

| 54 | IS 1110: 1990 | Ferrosilicon – specification |

| 55 | 4409:1973 | Specification for ferronickel |

| 56 | 1029 : 1970 | Specification for hot rolled steel strip (bailing) |

| 57 | IS 2385 :1997 | Specification for hot – rolled mild steel sheet and strip in coil form for cold – reduced tinplate and cold – reduced black plate |

| 58 | IS 3039 : 1988 | Specification for structural steel for construction of hulls of ships |

| 59 | IS 9550 2001 | Bright steel bars – v specification |

| 60 | IS 3748 : 2001 | Tool and die steels – specification |

| 61 | IS 5517 : 1993 | Steel for hardening and tempering – specification |

| 62 | IS 16732 : 2019 | Galvanized structural steel – specification |

| 63 | IS 7494 : 1981 | Specification for steel for valves for internal combustion engines |

| 64 | IS 12146 : 1987 | Specification for carbon manganese steel forgings for pressure vessels |

| 65 | IS 16585 : 2016 | Magnetic materials – specification for individual material – fe based amorphous strip delivered in the semi – processed state |

| 66 | IS 2831 : 2012 | Carbon steel cast billet ingots, billets, blooms and slabs for re – rolling into structural steel (ordinary quality) – specification |

| 67 | IS 1148: 2009 | Steel rivet bars (medium and high tensile) – for structural purpose |

| 68 | IS 1673 : 1984 | Specification for mild steel wire, cold heading quality |

| 69 | IS 1812 : 1982 | Specification for carbon steel wire for the manufacture of wood screws |

| 70 | IS 2507 : 1975 | Specification for cold – rolled steel strips for springs. |

| 71 | IS 2255 : 1977 | Specification for mild steel wire rod for the manufacture of machine screw (by cold heading process) |

| 72 | IS 3195 : 1992 | Steel for the manufacture of volute and helical springs (for railway rolling stock) – specification. |

| 73 | IS 3431 : 1982 | Specification for steel for the manufacture of volute, helical and laminated springs for automotive suspension. |

| 74 | IS 3885 : Part – 1 : 1992 | Steel for the manufacture of laminated springs (railway rolling stock) Part 1 flat sections – specification. |

| 75 | IS 3885 : Part – 2 : 1992 | Steel for the manufacture of laminated springs (railway rolling stock) Part 2: Rib and Groove sections – specification. |

| 76 | IS 4223 : 1975 | Specification for steel wire for umbrella ribs. |

| 77 | IS 4224 : 1972 | Specifications for steel wire for staples, pins and clips. |

| 78 | IS 4397 : 1999 | Cold – rolled carbon steel strips for balls and roller bearing cages/ retainers – specification. |

| 79 | IS 4398 : 1994 | Carbon – chromium steel for the manufacture of balls, rollers and bearing races – specification |

| 80 | IS 6902 : 1973 | Specification for steel wire for spokes. |

| 81 | IS 6967 : 1973 | Specification for steel for electrically welded round link chains. |

| 82 | IS 7226 : 1974 | Specification for cold rolled medium, high carbon and low alloy steel strip for general engineering purposes. |

| 83 | IS 7557 : 1982 | Specification for steel wire: (up to 20 mm) for the manufacture of cold – forged rivets. |

| 84 | IS 8052 : 2006 | Steel ingots, billets and blooms for the production of spring, rivets and screws for general engineering applications – specifications. |

| 85 | IS 8951 : 2001 | Steel cast billet ingots, billets and blooms for production of high carbon steel wire rods – specification |

| 86 | IS 8952 : 1995 | Steel ingots, blooms an billets for production of mild steel wire rods for general engineering purposes – specification |

| 87 | IS 9476 : 1980 | Specification for cold rolled steel strips for carbon steel razor blades. |

| 88 | IS 9962 : 1981 | Specification for steel wire for needles. |

| 89 | IS 17111 : 2019 | Heat – tested steels alloy and free – cutting steels – ball and roller bearing steels. |

| 90 | IS 14331 : 1995 | Steels for high temperature bolting applications – specification |

| 91 | IS 12594 : 1988 | Hot – dip zinc coating on structural steel bars for concrete reinforcement – specification |

| 92 | IS 14650 : 1999 | Carbon steel cast billet ingots, billets, blooms and slabs for rerolling purposes – specification |

| 93 | IS 4882 : 1979 | Specification for low carbon steel wire for rivets for use in bearing industry |

| 94 | IS 2090 : 1983 | Specification for high tensile steel bars used in pre- stressed concrete |

| 95 | IS 6529 : 1996 | Stainless steel blooms billets and slabs for forging |

| 96 | IS 9294 : 1979 | Cold – rolled stainless steel strips for razor blades |

| 97 | IS 10631 : 1983 | Stainless steel for welding electrode core wire |

| 98 | IS 10632 (Part 2): 1983 | Specification for non magnetic stainless steel for electrical applications Part 2 specific requirements for binding wire |

| 99 | IS 10632 (Part 3): 1983 | Specification for non magnetic stainless steel for electrical applications Part 3 specific requirements for sheets, strips and plates. |

| 100 | IS 11169 (Part 2) : 1989 | Steels for cold heading/cold extrusion applications – specification Part 2 stainless steel |

| 101 | IS 5651 : 1987 | Steels for pneumatic tools |

| 102 | IS 9516 : 1980 | Heat resistance steels |

| 103 | IS 11952 : 1986 | Steels for piston pins (gudgeon pins) |

| 104 | IS 12045 : 1987 | Alloy used in electrical resistance metallic heating elements |

| 105 | IS 14652 : 1999 | 18 percent nickel merging steel bars and rods |

| 106 | IS 1566 : 1982 | Specification for hard – drawn steel wire fabric for concrete reinforcement |

| 107 | IS 1170 : 1992 | Ferrochromium – specification |

| 108 | IS 11946 : 1987 | Soft magnetic iron strips |

| 109 | IS 11947 : 1987 | Soft magnetic iron rods, bars flats and sections |

| 110 | IS 963 : 1958 | Chrome molybdenum steel bars and rods for aircraft purposes |

| 111 | IS 4454 : (Part 4): 2001 | Steel wires for mechanical springs – Part 4 : stainless steel wire |

| 112 | IS 1993 : 2018 | Cold – reduced electrolytic tin plate |

| 113 | IS 12591 : 2018 | Cold – reduced electrolytic chromium/chromium oxide – coated steel |

| 114 | IS 412 : 1975 | Expanded metal steel sheets for general purposes |

| 115 | IS 2100 : 1970 | Steel billets, bars, and sections for boilers |

| 116 | IS 2589 : 1975 | Hard drawn steel wire for upholstery springs |

| 117 | IS 3298 : 1981 | Mild steel rivet bars for ship building |

| 118 | IS 4072 : 1975 | Steel for spring washers |

| 119 | IS 8510 (Part II): 1977 | Steel wire for banding of armatures and rators Part II specific requirements for magnetic banding wires |

| 120 | IS 8510 (Part III): 1977 | Tinned steel wire for banding of armatures and rotors Part III specific requirements for non – magnetic banding wires |

| 121 | IS 8563 : 1977 | Half round mild steel wire for the manufacture of split pins |

| 122 | IS 8564 : 1977 | Steel wire for nipples for spokes |

| 123 | IS 8565 : 1977 | Healed wire |

| 124 | IS 8566 : 1977 | Steel wire for reeds |

| 125 | IS 8917 : 1978 | Plates for galvanizing pots |

| 126 | IS 9442 : 1980 | Hot rolled steel plates sheets and strips for manufacture of agricultural discs |

| 127 | IS 9485 : 1980 | Cold – reduced and hot – rolled carbon steel sheet for porcelain enameling |

| 128 | IS 10794 : 1984 | Mild steel wire for cotter pins |

| 129 | IS 12262 : 1988 | Trapezoidal steel wire for springs washer |

| 130 | IS 1470 : 2013 | Silicomanganese – specification |

| 131 | IS 15911 : 2010 | Structural steel (ordinary quality) |

| 132 | IS 1171 : 2011 | Ferromanganese – specification |

| 133 | IS 4431 : 1978 | Carbon and carbon – manganese free – cutting steels |

| 134 | IS 4432 : 1988 | Case hardening steels |

| 135 | IS 5518 : 1996 | Steels for die blocks for drop forging |

| 136 | IS 8748 : 1978 | Forged/ rolled CTC segments |

| 137 | IS 12145 : 1987 | Quenched and tempered alloy steel forgings for pressure vessels |

| 138 | IS 13387 : 1992 | Tool steel forgings for metal foaming |

| 139 | IS 14698 : 1999 | Carbon and low alloy billets, blooms, slabs and bars for manufacture of shell bodies and proof shots used in defense services |

| 140 | IS/ISO 11951 : 2016 | Cold – reduced tin mill products – black plate |

| 141 | IS 3930 : 1994 | Flame and induction hardening steels |

| 142 | IS 5478 : 1969 | Thermostat metal sheet and strip |

| 143 | IS 13352 : 1992 | Stock for forgings produced from continuously cast blooms, billets and slabs |

| 144 | IS 16644 : 2018 | Stress – relieved, low relaxation steel wire for pre- stressed concrete |

| 145 | IS 17404 : 2020 | Electro galvanized hot rolled and cold reduced carbon steel sheets and strips |

| 146 | IS 8329 : 2000 | Centrifugally cast (spun) ductile iron pressure pipes for water, gas and sewage |

| 147 | IS 9523 : 2000 | Ductile iron fittings for pressure pipes for water, gas and sewage |

| 148 | IS 1161 : 2014 | Steel tubes for structural purposes |

| 149 | IS 1239 (Part 1) : 2014 | Steel tubes, tubular and other wrought steel fittings – Part 1 : steel tubes |

| 150 | IS 4270 : 2001 | Steel tubes used for water – wells (upto 200 mm dia) |

| 151 | IS 9139 : 1979 | Specification for malleable iron shots and grits for use in foundries |

| 152 | IS 1180 (Part 1) | Out door type oil immersed distribution transformers upto and including 2500 KVA, 33 KV – specification Part 1 mineral oil immersed |

| 153 | IS 12615 | Energy efficient including motors – three phase squirrel |

| 154 | IS 2993 | A.C. motor capacitors |

| 155 | IS 13340 | Power capacitors of self – healing type for AC power systems having rated voltage up to 650V |

| 156 | IS 13585 Part 1 | Shunt power capacitors of the non – self healing type for AC system having a rated voltage up to and including 1000v Part – 1 general performance, testing and rating safety requirements guide for installation and operation |

REQUIREMENTS COVERED IN VARIOUS INDIAN STANDARDS ON STEEL AND STEEL PRODUCTS

BIS has formulated a comprehensive set of standards covering diverse aspects of steel production and utilization. These standards, integral to the BIS certification process, encompass steel ingots, billets, plates, sheets, wires, rods, structural steels, steel ropes, and more. They delineate specifications, testing methods, and performance criteria to be met by manufacturers, fostering consistency and reliability in steel manufacturing processes. Compliance with these standards not only ensures product quality but also facilitates interoperability and compatibility in various applications—a crucial aspect validated during BIS certification assessments.

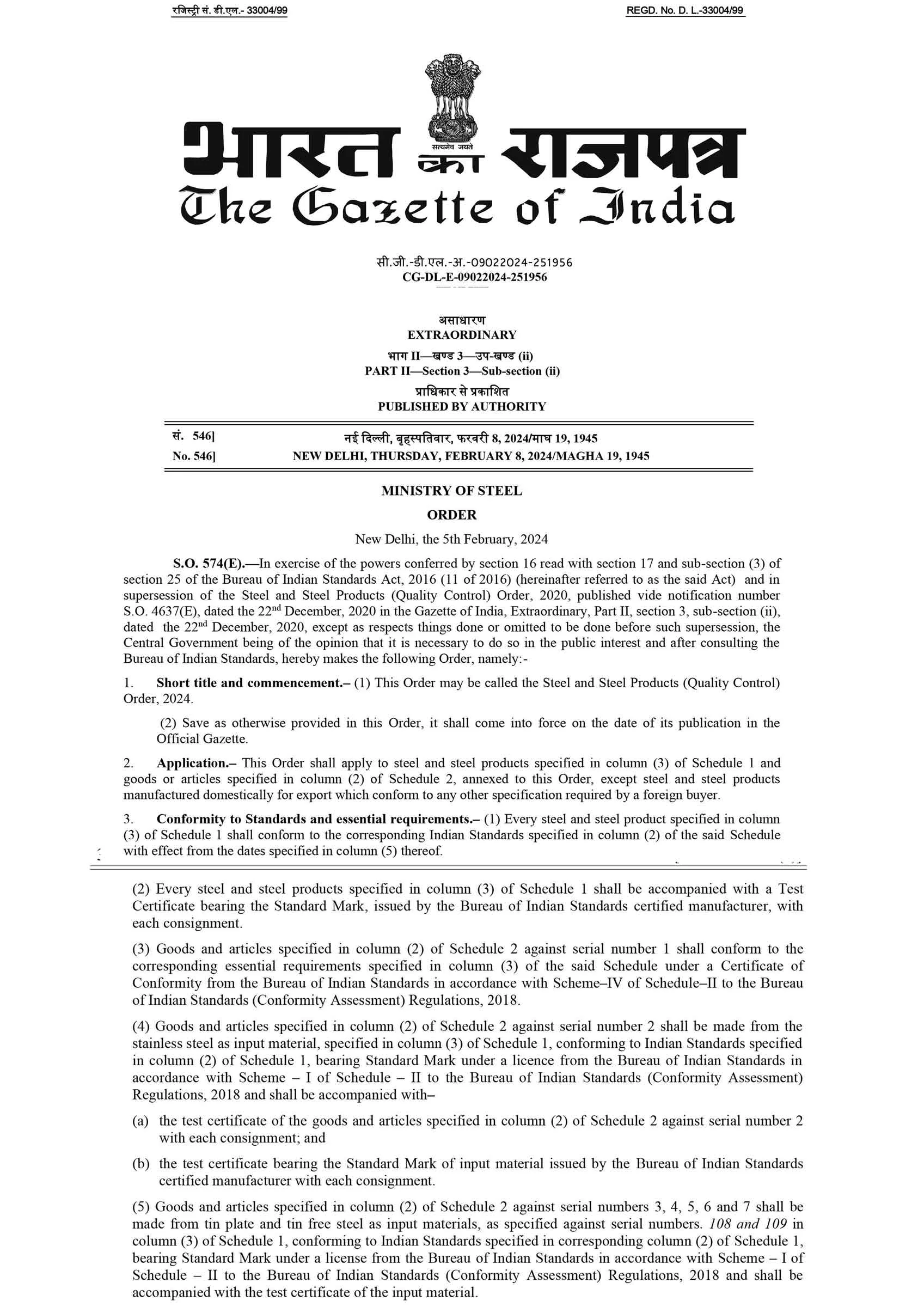

QUALITY CONTROL ORDERS

The Ministry of Steel, Government of India, has issued Quality Control Orders on numerous steel products, mandating compliance with specific Indian standards as part of the BIS certification framework. These orders aim to ensure that steel products meet the required quality benchmarks, thereby enhancing their reliability and safety across various industries. By making adherence to Indian standards mandatory through BIS certification, these orders underscore the significance of quality assurance in the steel sector.

BIS CERTIFICATION SCHEME FOR STEEL AND STEEL PRODUCTS

BIS operates a certification scheme that validates compliance with Indian standards for steel and steel products. Through this scheme, manufacturers undergo rigorous evaluation and testing of their products to demonstrate conformity with specified standards. This BIS certification process ensures that the products meet the stringent quality requirements set by BIS. Upon successful assessment, BIS grants certification, affirming the product’s quality and compliance with regulatory requirements. This certification serves as a hallmark of reliability and trustworthiness, enhancing market acceptance and competitiveness for certified products.

ROLE OF OMEGA QMS PVT. LTD.

Omega QMS Pvt. Ltd. stands at the forefront of providing technical assistance to manufacturers, both in India and overseas, navigating the complexities of the BIS certification process. With their profound expertise and domain knowledge, Omega QMS Pvt. Ltd. guides manufacturers through every stage of BIS certification, from understanding requirements to facilitating testing and documentation. Their tailored solutions and meticulous approach ensure seamless compliance with BIS standards, empowering manufacturers to meet regulatory mandates and market demands effectively, ultimately securing BIS certification for their products.

CONCLUSION

In the dynamic landscape of steel manufacturing, adherence to BIS quality standards is non-negotiable. BIS certification, coupled with the enforcement of Quality Control Orders by the Ministry of Steel, reinforces the commitment to quality and safety in the steel sector. By embracing these BIS standards and certification processes, manufacturers uphold their credibility and reliability while fostering consumer trust. Omega QMS Pvt. Ltd. plays a pivotal role in this ecosystem, offering invaluable support and guidance to manufacturers seeking BIS certification, thereby contributing to the elevation of standards and quality in the steel industry, both domestically and globally.

908-909, Hemkunt House, Rajendra Place,New Delhi – 110008, India