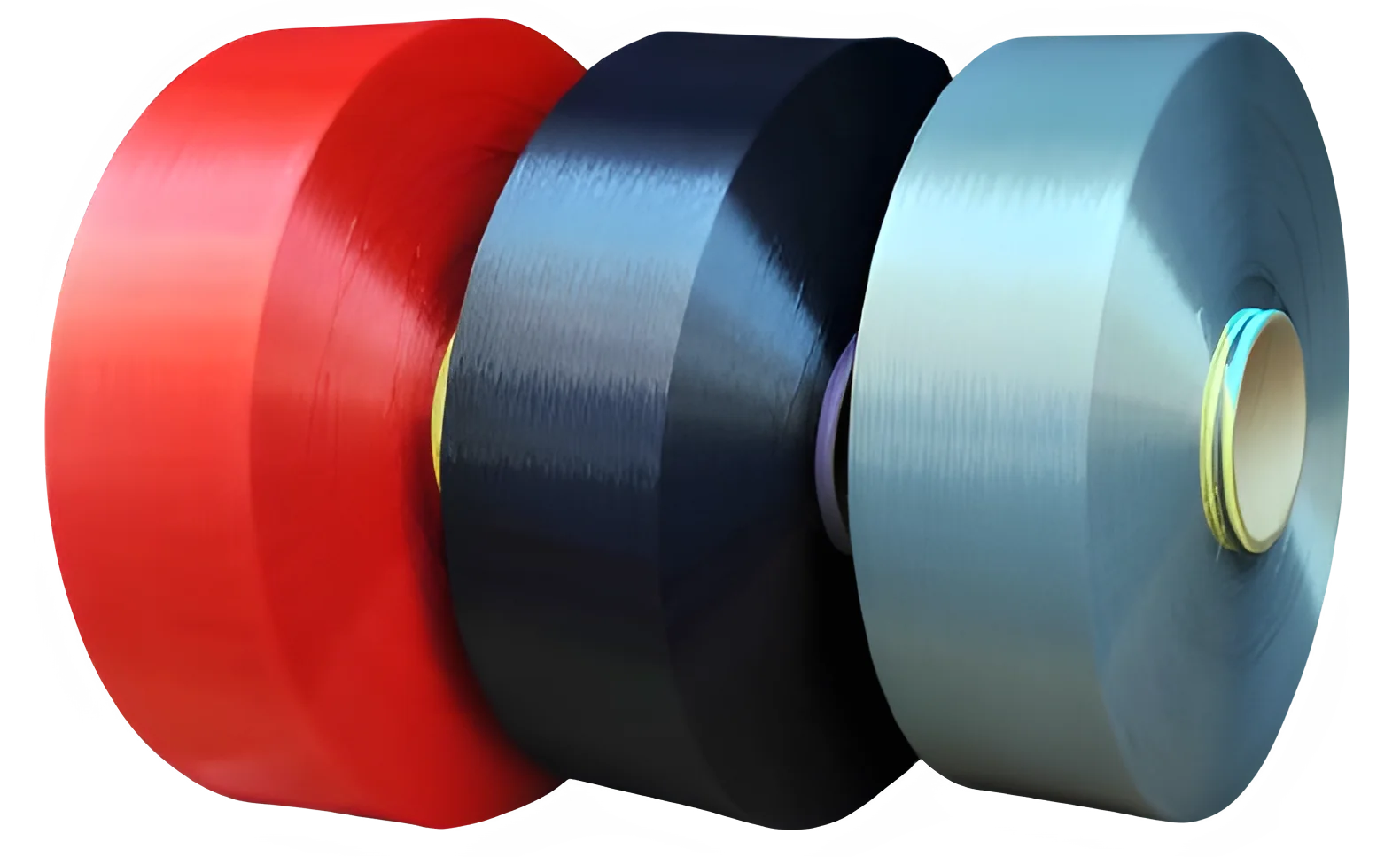

BIS Certification for Polyester POY (IS 17262:2019) – Omega QMS Pvt. Ltd.’s Expertise

The Polyester Partially Oriented Yarn (POY) sector now requires strict adherence to BIS standards under the Quality Control Order (QCO) 2023. Non-compliance can lead to penalties and restricted market access. With Omega QMS Pvt. Ltd., manufacturers gain a trusted partner to achieve BIS licensing efficiently while ensuring their products meet IS 17262:2019 quality benchmarks.

Omega QMS Pvt. Ltd., with its proven expertise in regulatory compliance, plays a crucial role in helping manufacturers meet these stringent requirements and secure the ISI mark for their POY products.

Polyester POY QCO 2023 – What Manufacturers Need to Know

The Polyester Partially Oriented Yarn (Quality Control) Order, 2023, effective from October 5, 2023, mandates that all POY products must:

- Conform to the specifications outlined in IS 17262:2019 – Textile: Polyester Partially Oriented Yarn – Specification.

- Carry the Standard Mark (ISI Mark)under a valid BIS license.

- Undergo testing and inspection as per BIS standards, ensuring quality in parameters such as denier, tenacity, elongation, and defect limits.

Non-compliance may result in penalties, legal action, and a ban on sale in the Indian market, as stipulated under the BIS Act, 2016.

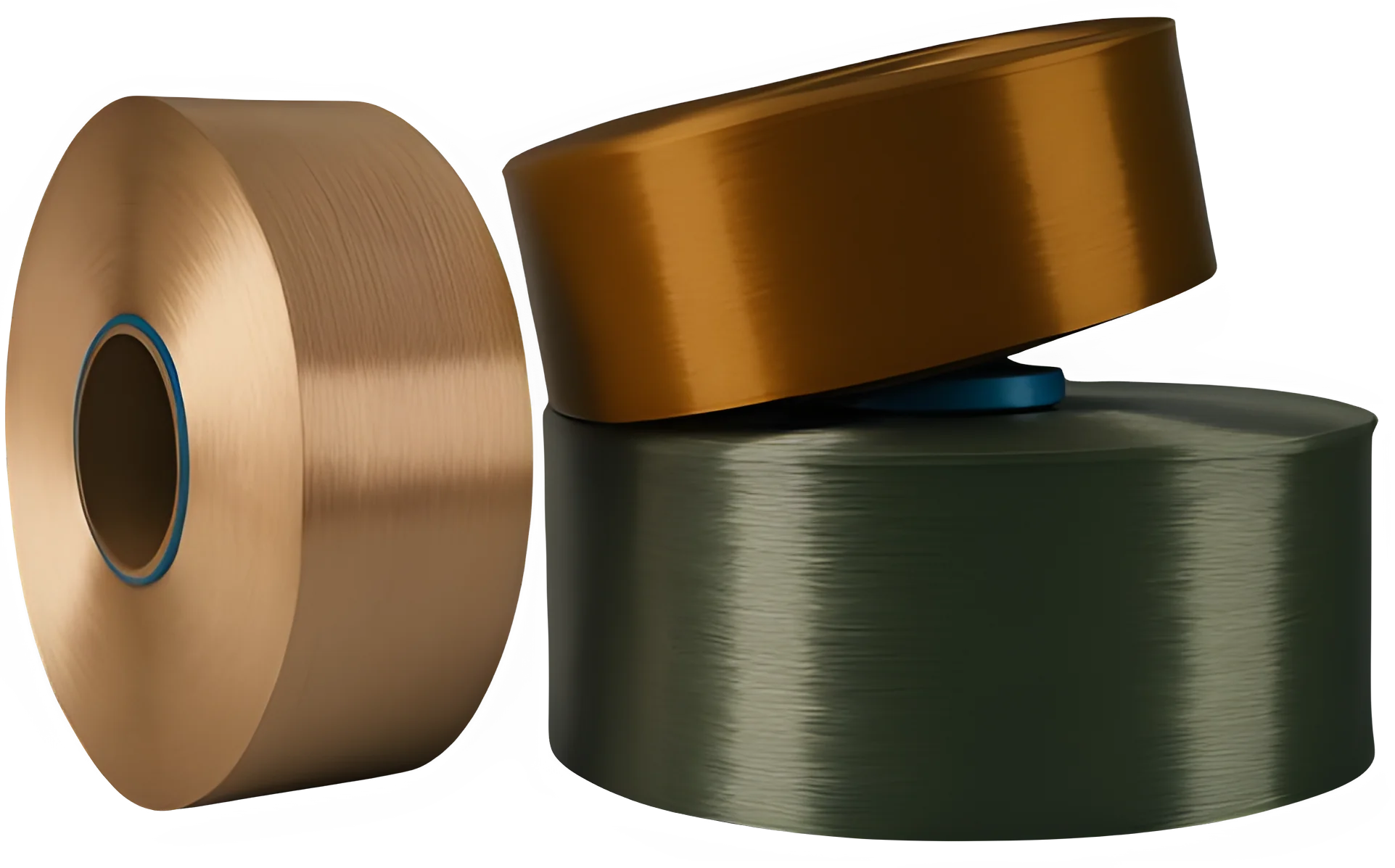

Key Highlights of IS 17262:2019

IS 17262:2019 lays down comprehensive quality requirements for Polyester Partially Oriented Yarns, including:

- Physical Properties: Linear density, tensile strength, elongation at break, shrinkage, and uniformity.

- Visual and Defect Controls: Limits on broken filaments, cross-ends, oil contamination, and other imperfections.

- Optional Eco-mark Compliance: Restriction of hazardous substances such as heavy metals, azo dyes, and formaldehyde.

Omega QMS Pvt. Ltd. – Your Partner for BIS Certification

Navigating BIS compliance and licensing can be challenging for manufacturers. Omega QMS Pvt. Ltd. provides complete end-to-end consulting support, including:

- Compliance Assessment

- Pre-certification audits to evaluate gaps against IS 17262:2019.

- Advisory on process improvements for quality assurance.

- Documentation & Application Support

- Preparation and filing of BIS applications.

- Drafting technical dossiers, quality manuals, and required test reports.

- Laboratory Testing Coordination

- Assistance with testing in BIS-recognized laboratories.

- Review and verification of lab results.

- BIS Audit & Liaison

- Factory readiness audits and staff training.

- Direct coordination with BIS officials to address queries and speed up certification.

- Post-Certification Support

- Guidance on proper ISI mark usage.

- License renewals, scope expansions, and ongoing compliance checks.

Why BIS Certification Matters

BIS certification not only ensures compliance with government mandates but also:

- Enhances brand reputation and market credibility.

- Enables smooth domestic and international trade.

- Protects manufacturers from legal and financial liabilities due to non-compliance.

Conclusion

With the Polyester POY QCO 2023 now fully enforced, timely action is critical for yarn manufacturers. Omega QMS Pvt. Ltd., with its extensive regulatory experience and proven track record in textile compliance, ensures a smooth and hassle-free BIS certification process for your POY products.

Contact Omega QMS Pvt. Ltd.

Email: info@globalomega.com | sales@globalomega.com

Phone: +91-11-41413939 (100 lines)

Website: www.globalomega.com