BIS CERTIFICATION OF PARTICLE BOARDS OF WOOD AND OTHER LIGNOCELLULOSIC MATERIALS (MEDIUM DENSITY) FOR GENERAL PURPOSES AS PER IS 3087:2005

INTRODUCTION

Particle boards, a fundamental component in various industries, serve as versatile materials with wide-ranging applications. From furniture manufacturing to construction, particle boards offer an economical and practical solution for diverse needs. Ensuring the quality and performance of these particle boards is paramount to meet industry standards and consumer expectations. In this context, the Indian Standard IS 3087 plays a pivotal role by providing comprehensive specifications for medium-density particle boards crafted from wood and other lignocellulosic materials. IS 3087 serves as a guiding framework for manufacturers, delineating the essential parameters to be met during the production process. It covers various aspects, including materials, manufacturing techniques, physical characteristics, and quality assurance measures, ensuring that the particle boards conform to stringent quality benchmarks.

IS 3087:2005 PARTICLE BOARDS OF WOOD AND OTHER LIGNOCELLULOSIC MATERIALS (MEDIUM DENSITY) FOR GENERAL PURPOSES AS PER

IS 3087 covers the requirements of medium density particle boards made of wood and/or other lignocellulosic materials for general purposes, having specific gravity in the range 0.5 to 0.9. This standard does not cover veneered particle boards, moulded particle boards, high and low density particle boards or particle boards faced by impregnated paper surfaces. Any species of wood and/or other lignocellulosic materials may be used in the manufacture of particle board. Particles of wood or other lignocellulosic materials for the manufacture of particle boards shall be produced by cutting wood and/or any other suitable lignocellulosic materials into shavings, flakes, splinters or slivers on a suitable chipping machine. The particles shall be dried in a mechanical drier. The dried particles shall be graded to required sizes and thoroughly blended with the requisite quantity of adhesives in mechanical mixers or applicators. The required sizing material may be added at this stage, either mixed with the binder or separately introduced into the mixer. Care shall be taken that the moisture content of the binder does not excessively increase the moisture content of the chips. The well-blended chips are then formed in to a mat and pressed into panels by passing into the pressing machine under controlled heat, pressure and time conditions. The hot pressed boards are subsequently cooled, conditioned to attain equilibrium moisture content and sanded on both sides to attain uniform thickness and finally trimmed and cut to standard size

in the range 0.5 to 0.9. This standard does not cover veneered particle boards, moulded particle boards, high and low density particle boards or particle boards faced by impregnated paper surfaces. Any species of wood and/or other lignocellulosic materials may be used in the manufacture of particle board. Particles of wood or other lignocellulosic materials for the manufacture of particle boards shall be produced by cutting wood and/or any other suitable lignocellulosic materials into shavings, flakes, splinters or slivers on a suitable chipping machine. The particles shall be dried in a mechanical drier. The dried particles shall be graded to required sizes and thoroughly blended with the requisite quantity of adhesives in mechanical mixers or applicators. The required sizing material may be added at this stage, either mixed with the binder or separately introduced into the mixer. Care shall be taken that the moisture content of the binder does not excessively increase the moisture content of the chips. The well-blended chips are then formed in to a mat and pressed into panels by passing into the pressing machine under controlled heat, pressure and time conditions. The hot pressed boards are subsequently cooled, conditioned to attain equilibrium moisture content and sanded on both sides to attain uniform thickness and finally trimmed and cut to standard size

The standard also delves into the physical characteristics expected of particle boards, covering aspects like density, moisture content, water absorption, swelling, and workability. Additionally, it outlines sampling and inspection procedures to verify compliance with the prescribed standards, ensuring consistent quality across batches.

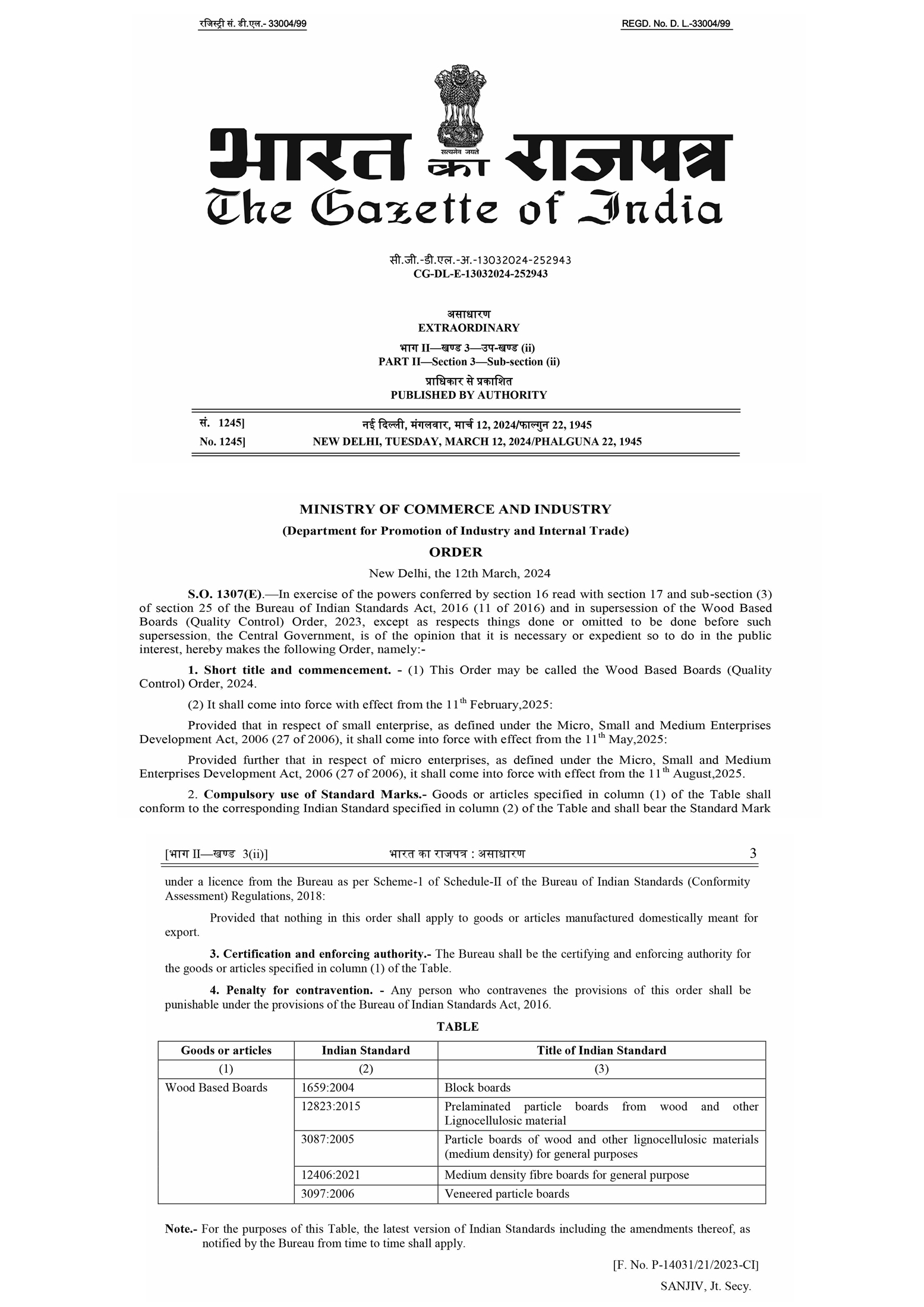

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 12 MARCH 2024 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for particle boards as mentioned above to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark (ISI Mark ) of the Bureau of Indian Standards under a valid BIS license. In short, it has become obligatory for all the manufacturers of particle boards, whether in India or overseas, to immediately apply for BIS license and obtain a valid BIS certification license before that the last date of implementation of the order, i.e., 11 February 2025.

BIS CERTIFICATION SCHEME FOR PARTICLE BOARDS ACCORDING TO IS 3087:2005

The BIS Certification Scheme is a crucial framework established by the Indian government to ensure that products available in the market meet high standards of quality, safety, and reliability. This scheme is designed to protect consumer interests by establishing rigorous benchmarks and guidelines that products must adhere to before being considered compliant. BIS certification applies across various industries and products, covering a broad spectrum of industrial and manufacturing activities. Here’s a simplified breakdown of the steps involved in the BIS Certification process:

- Standard Identification: Manufacturers identify the relevant BIS standard applicable to their product category, such as IS 3087. These standards outline specific requirements for quality, safety, and performance that the product must meet.

- Application Submission: Manufacturers submit an application for BIS certification to the Bureau of Indian Standards (BIS), providing detailed information about the product, its specifications, and the desired certification mark.

- Factory Inspection: BIS conducts an inspection of the manufacturer’s production facility to evaluate quality control processes, infrastructure, and adherence to relevant standards.

- Sample Testing: BIS collects samples of the product from the manufacturer for testing in authorized BIS laboratories or recognized testing centres. These tests assess various parameters specified by the BIS standard.

- Certification Decision: Based on satisfactory test results and compliance with standards, BIS decides whether to grant certification to the product. If approved, the manufacturer is issued a BIS certification license.

- Regular Monitoring: BIS monitors the manufacturing process of certified products through periodic audits and market surveillance to ensure ongoing compliance with quality control processes and standards.

OMEGA QMS PVT. LTD. – YOUR PARTNER FOR SUCCESS

In the journey to achieve BIS certification and maintain exceptional product quality, Omega QMS Pvt. Ltd. stands out as a valuable partner for manufacturers. With a global presence and a proven track record of successful collaborations with Fortune 500 companies, Omega QMS offers a comprehensive range of services tailored to streamline the certification process and ensure compliance with industry standards.

Expert Guidance: Omega provides access to a team of seasoned experts with extensive knowledge of regulatory requirements, industry best practices, and the intricacies of the certification process. These experts guide manufacturers through the complex landscape, offering insights and strategies to navigate the process efficiently.

Testing and Validation: Omega assists manufacturers in planning and executing necessary tests and validations required for BIS certification.

Documentation and Compliance: Achieving BIS certification demands meticulous documentation of processes, materials, and testing procedures. Omega supports manufacturers in creating comprehensive and accurate documentation aligned with BIS requirements, minimizing the risk of errors and rejections.

Inspection Support: Omega prepares manufacturers for BIS audits, ensuring they are well-prepared to address any issues that may arise and increase the likelihood of a successful outcome.

Customized Approach: Recognizing that each manufacturer’s journey toward BIS certification is unique, Omega tailors its services to fit specific needs, challenges, and goals, ensuring a personalized and effective approach.

Global Experience: With a presence in over 40 countries, Omega brings global experience to the table, offering insights into varying regulatory environments and industry practices, enabling manufacturers to excel globally.

Omega QMS Pvt. Ltd. serves as a strategic partner for manufacturers seeking BIS Certification for Particle Boards as per IS 3087. Its comprehensive approach encompasses expert guidance, process control, testing and validation support, documentation assistance, audit preparation, training, and a global perspective. By collaborating with Omega, manufacturers gain a competitive edge in their pursuit of certification while upholding the highest standards of product quality and consumer satisfaction.

CONCLUSION

IS 3087 serves as a benchmark for ensuring the quality and performance of particle boards used for general purposes. Compliance with this standard is essential to deliver products that meet prescribed specifications and exhibit optimal characteristics. BIS certification further reinforces the commitment to quality and enables manufacturers to establish credibility and trust among consumers. With the support of consultancy firms like Omega QMS Pvt. Ltd., manufacturers can navigate the certification process seamlessly, paving the way for market acceptance and success.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Comment (1)

I went over this website and I conceive you have a lot of superb info , saved to fav (:.