BIS Certification for Furniture as per IS 17631, 17632, IS 17633, IS 17634, IS 17635 AND IS 17736

In today’s rapidly evolving world, quality and safety standards have become paramount across all industries. When it comes to the manufacturing and sale of furniture, the Bureau of Indian Standards (BIS) Certification is a key element to ensure that the products meet the necessary quality benchmarks. This article explores the importance of BIS Certification for various types of furniture, including work chairs, general purpose chairs and stools, tables and desks, storage units, beds, and bunk beds. Additionally, we will highlight how Omega QMS Pvt Ltd assists manufacturers in obtaining BIS Certification for their furniture products.

IS 17631 WORK CHAIRS

In this standard, the requirements related to the performance and safety in terms of strength, stability and durability for work chairs have been specified. This standard applies to completely manufactured/fabricated work chairs. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. The tests are designed to evaluate properties without regard to materials, design/construction or manufacturing processes. The forces and dimensions are applicable to work chairs intended for adult persons. The tests given in the standard are to check against surface requirements and the application, to various parts of the item, forces simulating normal functional use, as well as misuse that can reasonably be expected to occur. The loads and cycles specified in the requirements of this standard are for all types of work chairs irrespective of their construction or materials used. Usage of these performance criteria for work chairs in industrial areas not identical to office use are not covered in the scope of this standard

In this standard, the requirements related to the performance and safety in terms of strength, stability and durability for work chairs have been specified. This standard applies to completely manufactured/fabricated work chairs. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. The tests are designed to evaluate properties without regard to materials, design/construction or manufacturing processes. The forces and dimensions are applicable to work chairs intended for adult persons. The tests given in the standard are to check against surface requirements and the application, to various parts of the item, forces simulating normal functional use, as well as misuse that can reasonably be expected to occur. The loads and cycles specified in the requirements of this standard are for all types of work chairs irrespective of their construction or materials used. Usage of these performance criteria for work chairs in industrial areas not identical to office use are not covered in the scope of this standard

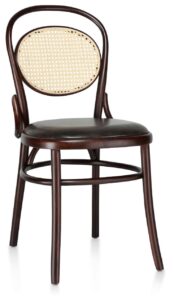

IS 17632:2022 GENERAL PURPOSE CHAIRS AND STOOLS

In this standard, the requirements related to the performance and safety in the term of strength, stability and durability for general purpose chair and stool have been specified. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. This standard does not apply to test for reclining or tilting chairs. It also does not apply to settees and other multiple seating, nor to rocking chairs. The tests are designed to be applied to an article of furniture that is fully assembled and ready for use. The Standard does not include tests for work chairs with swivel and chair base having castors or studs covered under IS 17631 : 2021 Work chairs — Specification. For the purpose of this standard, pouffes are considered as stools. Assessment of ageing and degradation is not included. The tests are not intended to assess the durability of stuffing materials, upholstery fabrics or foam cushions. Forces and dimensions in the tests are applicable to chairs and stools intended for adult persons

In this standard, the requirements related to the performance and safety in the term of strength, stability and durability for general purpose chair and stool have been specified. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. This standard does not apply to test for reclining or tilting chairs. It also does not apply to settees and other multiple seating, nor to rocking chairs. The tests are designed to be applied to an article of furniture that is fully assembled and ready for use. The Standard does not include tests for work chairs with swivel and chair base having castors or studs covered under IS 17631 : 2021 Work chairs — Specification. For the purpose of this standard, pouffes are considered as stools. Assessment of ageing and degradation is not included. The tests are not intended to assess the durability of stuffing materials, upholstery fabrics or foam cushions. Forces and dimensions in the tests are applicable to chairs and stools intended for adult persons

IS 17633:2022 TABLES AND DESKS

In this version the requirements related to the performance and safety of tables and desks have been specified, designed for tables undertaken in a seated, a sit-stand or standing position, used by adults, including those with glass in their construction, used by adults, including those with glass in their construction. This standard applies to completely manufactured/fabricated tables and desks. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. The tests consist of requirements for office as well as domestic applications, simulating normal functional use, as well as misuse that can reasonably be expected to occur. Tests carried out according to this standard are intended to demonstrate the ability of the item to give satisfactory service in its intended environment. It is necessary to understand that such tests do not ensure that structural failure will not eventually occur as a result of habitual misuse or after an excessively long period of service. This standard does not contain test methods for storage elements. Assessment of ageing and degradation is also not included in this standard.

In this version the requirements related to the performance and safety of tables and desks have been specified, designed for tables undertaken in a seated, a sit-stand or standing position, used by adults, including those with glass in their construction, used by adults, including those with glass in their construction. This standard applies to completely manufactured/fabricated tables and desks. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. The tests consist of requirements for office as well as domestic applications, simulating normal functional use, as well as misuse that can reasonably be expected to occur. Tests carried out according to this standard are intended to demonstrate the ability of the item to give satisfactory service in its intended environment. It is necessary to understand that such tests do not ensure that structural failure will not eventually occur as a result of habitual misuse or after an excessively long period of service. This standard does not contain test methods for storage elements. Assessment of ageing and degradation is also not included in this standard.

IS 17634:2022 STORAGE UNITS

In this version, the requirements related to the performance and safety in terms of strength, stability and durability of storage units, including their movable and non-movable parts intended for domestic usage and for institutional usage have been specified. This standard applies to completely manufactured/fabricated storage units. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. The tests consist of the application, to various parts of the unit, of loads, forces and velocities simulating normal functional use, as well as misuse, that might reasonably be expected to occur. With the exception of the sustained load tests in 7.2, the tests are designed to evaluate properties without regard to materials, design/construction or manufacturing processes. If the product is part of a range of multiple models, worst case(s) shall be determined which represents the whole range for testing. The strength and durability tests do not assess the structure of the building, for example, the strength of wall hanging cabinets includes only the cabinet and the parts used for the attachment. The wall and the attachment into the wall are not included.

In this version, the requirements related to the performance and safety in terms of strength, stability and durability of storage units, including their movable and non-movable parts intended for domestic usage and for institutional usage have been specified. This standard applies to completely manufactured/fabricated storage units. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. The tests consist of the application, to various parts of the unit, of loads, forces and velocities simulating normal functional use, as well as misuse, that might reasonably be expected to occur. With the exception of the sustained load tests in 7.2, the tests are designed to evaluate properties without regard to materials, design/construction or manufacturing processes. If the product is part of a range of multiple models, worst case(s) shall be determined which represents the whole range for testing. The strength and durability tests do not assess the structure of the building, for example, the strength of wall hanging cabinets includes only the cabinet and the parts used for the attachment. The wall and the attachment into the wall are not included.

IS 17635:2022 BEDS

In this version, the requirements related to the performance and safety of beds for adult for domestic and non-domestic use have been specified. This standard applies to completely manufactured/fabricated beds. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. This standard does not cover waterbeds, airbeds, foldaway beds, bunk beds and beds for people with special needs, nor the beds for healthcare and medical purposes. Test methods for the assessment of ageing, degradation, fire resistance and electrical functions are not included in this standard. Other features associated with beds including electrical adjustability or conversion from a sofa to a bed are not covered in this standard. The figures given in this standard are typical and the test procedures shall be followed..

In this version, the requirements related to the performance and safety of beds for adult for domestic and non-domestic use have been specified. This standard applies to completely manufactured/fabricated beds. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. This standard does not cover waterbeds, airbeds, foldaway beds, bunk beds and beds for people with special needs, nor the beds for healthcare and medical purposes. Test methods for the assessment of ageing, degradation, fire resistance and electrical functions are not included in this standard. Other features associated with beds including electrical adjustability or conversion from a sofa to a bed are not covered in this standard. The figures given in this standard are typical and the test procedures shall be followed..

IS 17636:2022 BUNK BEDS

This standard specifies requirements related to the performance and safety of bunk beds for domestic and nondomestic use. This standard also applies to single beds for use at a height of the bed base of 800 mm or more above finished floor level, irrespective of the use to which the space below is put. This standard applies to completely manufactured/fabricated beds. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. The tests are designed to be applied to a freestanding bunk bed that is fully assembled and ready for use. The tests consist of the application, to various parts of the bunk bed, of loads or forces simulating normal functional use, as well as misuse that can reasonably be expected to occur. They are designed to evaluate properties without regard to materials, design and construction, or manufacturing processes. Only the sleeping function is considered. The tests are designed to be applied to a freestanding bunk bed that is fully assembled and ready for use. The figures given in this Indian Standard are typical and the test procedures shall be followed.

This standard specifies requirements related to the performance and safety of bunk beds for domestic and nondomestic use. This standard also applies to single beds for use at a height of the bed base of 800 mm or more above finished floor level, irrespective of the use to which the space below is put. This standard applies to completely manufactured/fabricated beds. It also applies to ready-to-assemble units; in that case the requirements of this standard shall apply to the assembled units. The tests are designed to be applied to a freestanding bunk bed that is fully assembled and ready for use. The tests consist of the application, to various parts of the bunk bed, of loads or forces simulating normal functional use, as well as misuse that can reasonably be expected to occur. They are designed to evaluate properties without regard to materials, design and construction, or manufacturing processes. Only the sleeping function is considered. The tests are designed to be applied to a freestanding bunk bed that is fully assembled and ready for use. The figures given in this Indian Standard are typical and the test procedures shall be followed.

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for all furniture items mentioned above to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence. In short, it has become obligatory for all the manufacturers of furniture, whether in India or overseas, to immediately apply for BIS licence and obtain a valid BIS certification licence before that the last date of implementation of the order.

BIS CERTIFICATION SCHEME

The BIS Standards, IS 17631 to IS 17636, establishes a comprehensive framework encompassing various quality parameters that fasteners must adhere to. The Bureau of Indian Standards Certification Scheme is a vital framework established by the Indian government to ensure the quality, safety, and reliability of products available in the market. This scheme aims to safeguard consumer interests by setting stringent benchmarks and guidelines that products must meet before they can be deemed compliant. BIS certification covers a wide range of industries and products, encompassing the entire gamut of industrial and manufacturing activity. Various steps involved in the BIS Certification process are enumerated below:

- Standard Identification: Manufacturers identify the relevant BIS standard that applies to their chosen product category. These standards outline the specific quality, safety, and performance requirements that the product must meet.

- Application Submission: Manufacturers submit an application for BIS certification to the Bureau of Indian Standards (BIS), providing details about the product, its specifications, and the desired certification mark.

- Factory Inspection: BIS conducts an inspection of the manufacturer’s production facility to assess the quality control processes, infrastructure, and adherence to relevant standards.

- Sample Testing: BIS collects samples of the product from the manufacturer for testing in authorized BIS laboratories or recognized testing centers. These tests evaluate various parameters specified by the BIS standard.

- Certification Decision: Based on the satisfactory test results and compliance with standards, BIS decides whether to grant certification to the product. If approved, the manufacturer is issued a BIS certification license.

- Regular Monitoring: BIS monitors the manufacturing process of certified products through periodic audits and market surveillance to ensure ongoing compliance with quality control processes and standards.

OMEGA QMS PVT. LTD. – PARTNERING FOR SUCCESS

In the pursuit of achieving BIS certification and maintaining the highest levels of product quality, Omega QMS Pvt. Ltd. emerges as an invaluable partner for manufacturers. Backed by a global presence and a stellar track record of successful collaborations with Fortune 500 companies, Omega QMS provides an extensive array of services designed to streamline the certification process and ensure compliance with industry standards.

- Expert Guidance: Omega brings together a team of seasoned experts who possess in-depth knowledge of regulatory requirements, industry best practices, and intricacies of certification process. These experts guide manufacturers through the complex landscape, offering insights and strategies to navigate the process efficiently.

- Testing and Validation: Omega assists manufacturers in planning and executing necessary tests and validations required for BIS certification.

- Documentation and Compliance: The journey toward BIS certification demands meticulous documentation of processes, materials, and testing procedures. Omega aids manufacturers in creating comprehensive and accurate documentation that aligns with BIS requirements, reducing the risk of errors and rejections.

- Audit Support: Omega prepares manufacturers for BIS audits, which are a crucial part of the certification process. With its expertise, the organization ensures that manufacturers are well-prepared for audits, addressing any issues that may arise and increasing the likelihood of a successful outcome.

- Customized Approach: Each manufacturer’s journey toward BIS certification is unique. Omega understands this and tailors its services to fit the specific needs, challenges, and goals of individual manufacturers, ensuring a personalized and effective approach.

- Global Experience: With presence in over 40 countries, Omega brings global experience to the table. This international exposure allows the organization to offer insights into varying regulatory environments and industry practices, enabling manufacturers to excel globally.

Omega QMS Pvt. Ltd. functions as a strategic partner for manufacturers aiming to achieve BIS Certification. Its multifaceted approach encompasses expert guidance, process control, testing and validation support, documentation assistance, audit preparation, training, and a global perspective. By collaborating with Omega, manufacturers gain a competitive edge in their pursuit of certification while upholding the highest standards of product quality and consumer satisfaction.

For more details you can reach out to Omega at info@globalomega.com.

In a market where quality and safety are paramount, BIS Certification for furniture products is not just a requirement but also a mark of trust and assurance for consumers. Manufacturers seeking to ensure that their furniture products meet the highest standards can rely on the expertise of Omega QMS Pvt Ltd to navigate the complex certification process. By partnering with Omega QMS Pvt Ltd, furniture manufacturers can provide their customers with the confidence that their products are built to last and adhere to the rigorous standards set by the Bureau of Indian Standards.

Comments (3)

Very energetic blog, I enjoyed that bit. Will there be a part 2?

Sir

Please Share The Documents And Charges For BIS Licence For Our Firm Jaiswal Enterprises (Furniture Manufacturer

Hi,

This is Tushar WANI, Quality Manager from Steelcase Asia Holdings,

We are looking for BIS, Certification for our Products, Industrial office chairs, Furniture etc.

kindly share how you will going to support to get it done.

regards,

Tushar WANI