BIS Certification of Stainless Steel Sinks for Domestic Purposes as per IS 13983:1994

In the modern household, the kitchen stands as a hub of culinary creativity and nourishment. Among the many elements that constitute a functional and aesthetically pleasing kitchen, stainless steel sinks hold a place of paramount importance. These sinks not only facilitate dishwashing but also add a touch of sophistication to the overall kitchen design. To ensure the safety and durability of these essential kitchen fixtures, the Bureau of Indian Standards (BIS) has introduced stringent guidelines encapsulated in IS 13983:1994. Let’s delve into the significance of BIS certification for stainless steel sinks and explore how Omega QMS Pvt Ltd can assist manufacturers in obtaining this coveted certification.

In the modern household, the kitchen stands as a hub of culinary creativity and nourishment. Among the many elements that constitute a functional and aesthetically pleasing kitchen, stainless steel sinks hold a place of paramount importance. These sinks not only facilitate dishwashing but also add a touch of sophistication to the overall kitchen design. To ensure the safety and durability of these essential kitchen fixtures, the Bureau of Indian Standards (BIS) has introduced stringent guidelines encapsulated in IS 13983:1994. Let’s delve into the significance of BIS certification for stainless steel sinks and explore how Omega QMS Pvt Ltd can assist manufacturers in obtaining this coveted certification.

UNDERSTANDING IS 13983:1994 STAINLESS STEEL SINKS FOR DOMESTIC PURPOSES

IS 13983:1994 sets the standards for quality, design, and performance. This standard covers various aspects, including dimensions, material composition, corrosion resistance, and performance under load. Moreover, the standard addresses dimensions and design to ensure that the sinks fit seamlessly into diverse kitchen layouts. This not only enhances functionality but also contributes to the overall aesthetics of the kitchen space.

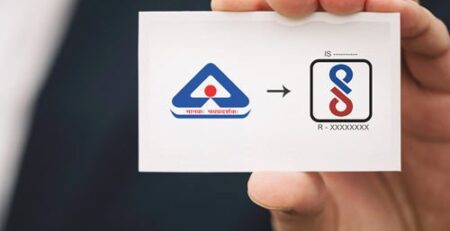

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 09 Aug 2023 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for all stainless steel sinks to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence. In short, it has become obligatory for all the manufacturers of stainless steel sinks, wherein in India or overseas, to immediately apply for BIS licence and obtain a valid BIS certification licence before that the last date of implementation of the order, i.e., 09 Feb 2024.

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for all stainless steel sinks to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence. In short, it has become obligatory for all the manufacturers of stainless steel sinks, wherein in India or overseas, to immediately apply for BIS licence and obtain a valid BIS certification licence before that the last date of implementation of the order, i.e., 09 Feb 2024.

BIS CERTIFICATION SCHEME

The BIS Standards, IS 13983:1994, establishes a comprehensive framework encompassing various quality parameters that stainless steel sinks must adhere to. The Bureau of Indian Standards Certification Scheme is a vital framework established by the Indian government to ensure the quality, safety, and reliability of products available in the market. This scheme aims to safeguard consumer interests by setting stringent benchmarks and guidelines that products must meet before they can be deemed compliant. BIS certification covers a wide range of industries and products, encompassing the entire gamut of industrial and manufacturing activity. Various steps involved in the BIS Certification process are enumerated below:

The BIS Standards, IS 13983:1994, establishes a comprehensive framework encompassing various quality parameters that stainless steel sinks must adhere to. The Bureau of Indian Standards Certification Scheme is a vital framework established by the Indian government to ensure the quality, safety, and reliability of products available in the market. This scheme aims to safeguard consumer interests by setting stringent benchmarks and guidelines that products must meet before they can be deemed compliant. BIS certification covers a wide range of industries and products, encompassing the entire gamut of industrial and manufacturing activity. Various steps involved in the BIS Certification process are enumerated below:

- Standard Identification: Manufacturers identify the relevant BIS standard that applies to their chosen product category. These standards outline the specific quality, safety, and performance requirements that the product must meet.

- Application Submission: Manufacturers submit an application for BIS certification to the Bureau of Indian Standards (BIS), providing details about the product, its specifications, and the desired certification mark.

- Factory Inspection: BIS conducts an inspection of the manufacturer’s production facility to assess the quality control processes, infrastructure, and adherence to relevant standards.

- Sample Testing: BIS collects samples of the product from the manufacturer for testing in authorized BIS laboratories or recognized testing centers. These tests evaluate various parameters specified by the BIS standard.

- Certification Decision: Based on the satisfactory test results and compliance with standards, BIS decides whether to grant certification to the product. If approved, the manufacturer is issued a BIS certification license.

- Regular Monitoring: BIS monitors the manufacturing process of certified products through periodic audits and market surveillance to ensure ongoing compliance with quality control processes and standards.

OMEGA QMS PVT. LTD. – PARTNERING FOR SUCCESS

In the pursuit of achieving BIS certification and maintaining the highest levels of product quality, Omega QMS Pvt. Ltd. emerges as an invaluable partner for manufacturers. Backed by a global presence and a stellar track record of successful collaborations with Fortune 500 companies, Omega QMS provides an extensive array of services designed to streamline the certification process and ensure compliance with industry standards.

- Expert Guidance: Omega brings together a team of seasoned experts who possess in-depth knowledge of regulatory requirements, industry best practices, and intricacies of certification process. These experts guide manufacturers through the complex landscape, offering insights and strategies to navigate the process efficiently.

- Testing and Validation: Omega assists manufacturers in planning and executing necessary tests and validations required for BIS certification.

- Documentation and Compliance: The journey toward BIS certification demands meticulous documentation of processes, materials, and testing procedures. Omega aids manufacturers in creating comprehensive and accurate documentation that aligns with BIS requirements, reducing the risk of errors and rejections.

- Audit Support: Omega prepares manufacturers for BIS audits, which are a crucial part of the certification process. With its expertise, the organization ensures that manufacturers are well-prepared for audits, addressing any issues that may arise and increasing the likelihood of a successful outcome.

- Customized Approach: Each manufacturer’s journey toward BIS certification is unique. Omega understands this and tailors its services to fit the specific needs, challenges, and goals of individual manufacturers, ensuring a personalized and effective approach.

- Global Experience: With presence in over 40 countries, Omega brings global experience to the table. This international exposure allows the organization to offer insights into varying regulatory environments and industry practices, enabling manufacturers to excel globally.

Omega QMS Pvt. Ltd. functions as a strategic partner for manufacturers aiming to achieve BIS Certification. Its multifaceted approach encompasses expert guidance, process control, testing and validation support, documentation assistance, audit preparation, training, and a global perspective. By collaborating with Omega, manufacturers gain a competitive edge in their pursuit of certification while upholding the highest standards of product quality and consumer satisfaction.

For more details you can reach out to Omega at info@globalomega.com

In conclusion, BIS certification for stainless steel sinks, as governed by IS 13983:1994, underscores the commitment to quality and safety in the manufacturing of domestic kitchen fixtures. This certification ensures that consumers can confidently choose sinks that meet rigorous quality benchmarks. Partnering with Omega QMS Pvt Ltd in this endeavor not only simplifies the certification process but also positions manufacturers for success in a competitive market. As stainless steel sinks continue to grace kitchens across the nation, BIS certification stands as a testament to their reliability, durability, and aesthetic appeal.

Leave a Reply