BIS CERTIFICATION OF WATER METERS (DOMESTIC TYPE), WATER METERS (BULK TYPE) AND FERRULES FOR WATER SERVICES AS PER IS 779:1994, 2373:1981 AND IS 2692:1989

INTRODUCTION

In today’s rapidly evolving world, ensuring the quality and reliability of products has become paramount. This is particularly true in sectors critical to public health and infrastructure, such as the water supply industry. Water meters, both for domestic and bulk usage, along with ferrules for water services, play crucial roles in monitoring and managing water distribution systems. To uphold the highest standards of quality and performance in these products, regulatory bodies like the Bureau of Indian Standards (BIS) have instituted certification schemes.

BIS certification serves as a mark of quality, safety, and reliability for products in various industries, including water management. Compliance with BIS standards ensures that products meet specific criteria related to performance, durability, and safety, as outlined in the respective Indian Standards (IS). For water meters (domestic type), water meters (bulk type), and ferrules for water services, adherence to IS 779, IS 2373, and IS 2692 respectively is essential.

INDIAN STANDARDS

IS 779:1994 WATER METERS (DOMESTIC TYPE)

IS 779:1994 WATER METERS (DOMESTIC TYPE)

This standard covers terminology, construction, technical characteristics, metrological characteristics and other requirements of water meters with threaded end connections of size up to and including 50 mm, having nominal flow rates in the range of 1.5to 15kl/b, suitable for measuring the flow of cold potable water at a nominal pressure of 1 MPa1) (Max) and ambient temperature. This standard is applicable both for semi positive (piston type) and inferential (turbine type) including magnetic type water meters having dry or wet dial. Based on the maximum verification scale interval and metrological characteristics, meters have been classified as class ‘0’, class ‘N and class ‘B’. Indicating device shall be able to record 9999 kJ (min) for meter size of 15, 20 and 25 nun and 99999 kJ (min) for size 40 and 5O mm and shall thereafter indicate zero. Pressure Tightness, Loss of Pressure, Metering Accuracy, Minimum Starting Flow and Temperature suitability are some of the performance tests specified for water meters.

IS 2373:1981 WATER METERS (BULK TYPE)

This standard covers bulk type water meters of the following types: a) Vane-wheel (impeller) type water meters from 50 to 300 mm and b) Helical type water meters from 50 to 500 mm. Water meters and their parts, especially parts coming in continuous contact with water, shall be made of materials resistant to corrosion and shall be non-toxic and non-tainting; where cast iron is used, it shall be protected suitably against corrosion. Use of dissimilar metals in contact under water shall be avoided, as far as possible, to minimize electrolytic corrosion. The water meter shall be provided with flanges at both the ends, the internal diameter of which shall be equal to the nominal size of the meter. The flanges shall be machined flat, that is, without a raised joint face. The meter shall be suitable for use with water up to 45ºC. Meters shall satisfactorily withstand a pressure of 1.6 MPa (16 kgf/cm2). The metering accuracy shall be ± 2 percent for both types of water meters.

IS 2692:1989 FERRULES FOR WATER SERVICES

IS 2692:1989 FERRULES FOR WATER SERVICES

This standard lays down nominal sizes and requirements regarding material, manufacture and workmanship, construction, sampling and testing of copper alloy screw-down ferrules for use on water supply mains. Ferrules shall be of the following nominal sizes: 8, 10, 15,20, 25, 32,40 and 50 mm . The nominal sizes of the ferrule shall be designated by the nominal bore of the inlet connection. All castings shall be sound, free from laps, blow holes and pittings; and both the external and internal surfaces shall be clean, smooth and free from sand. They shall be neatly dressed and no castings shall be burned, plugged, stopped or patched. Bodies, plugs and other parts shall be truly machined so that when assembled the parts shall be axial, parallel and cylindrical, with surfaces smoothly finished. Every ferrule, complete with its component parts, shall withstand a hydraulic pressure of at least 1.5 MPa, applied for two minutes, and during this period it shall neither leak nor sweat.

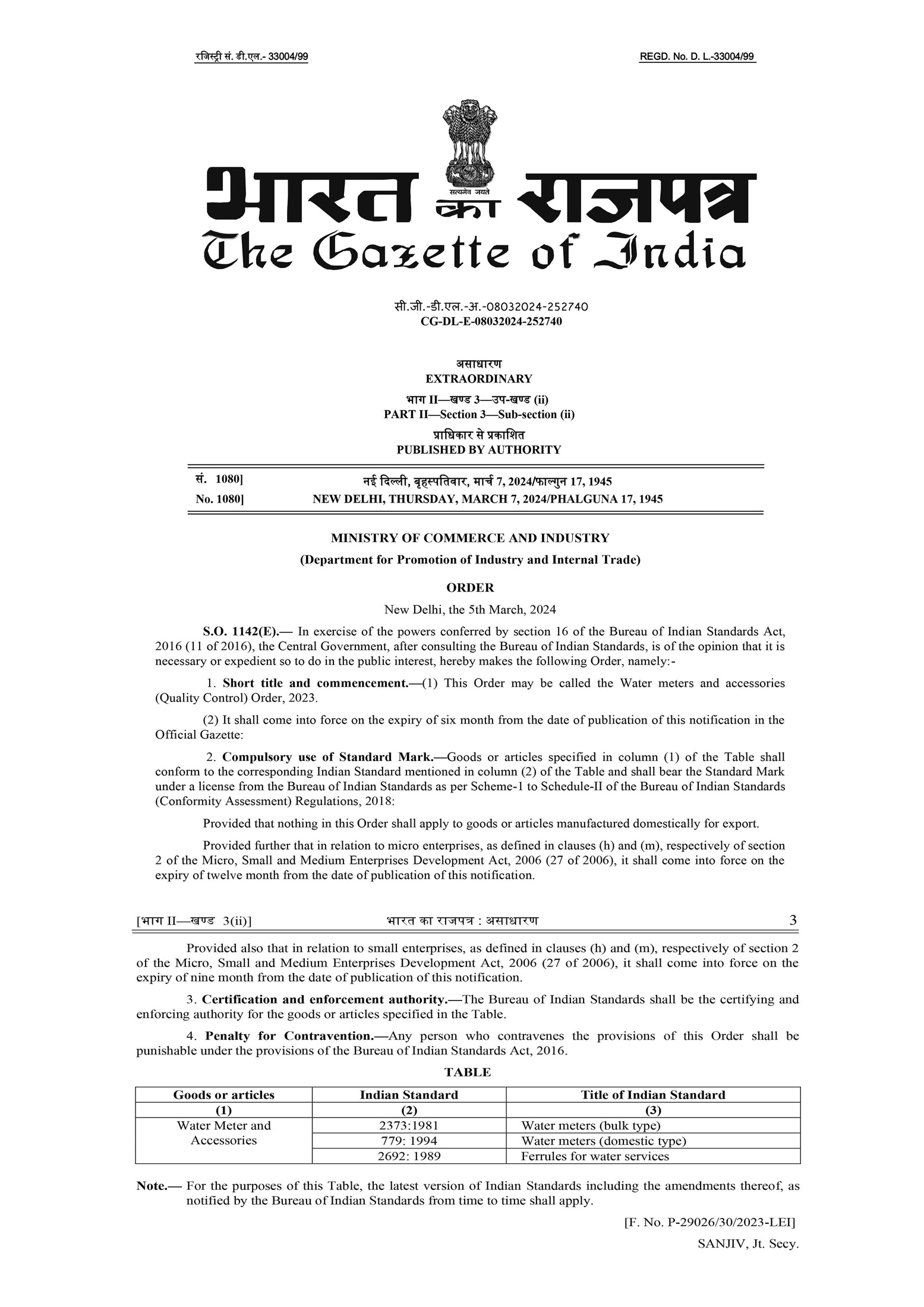

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 05 MARCH 2024 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for water meters as mentioned above to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark (ISI Mark ) of the Bureau of Indian Standards under a valid BIS license. In short, it has become obligatory for all the manufacturers of water meters, whether in India or overseas, to immediately apply for BIS license and obtain a valid BIS certification license before that the last date of implementation of the order, i.e., 04 September 2024.

BIS CERTIFICATION SCHEME FOR WATER METERS AND FERRULES

BIS CERTIFICATION SCHEME FOR WATER METERS AND FERRULES

The BIS Certification Scheme is a crucial framework established by the Indian government to ensure that products available in the market meet high standards of quality, safety, and reliability. This scheme is designed to protect consumer interests by establishing rigorous benchmarks and guidelines that products must adhere to before being considered compliant. BIS certification applies across various industries and products, covering a broad spectrum of industrial and manufacturing activities. Here’s a simplified breakdown of the steps involved in the BIS Certification process:

- Standard Identification: Manufacturers identify the relevant BIS standard applicable to their product category, such as IS 779, 2373 and 2692. These standards outline specific requirements for quality, safety, and performance that the product must meet.

- Application Submission: Manufacturers submit an application for BIS certification to the Bureau of Indian Standards (BIS), providing detailed information about the product, its specifications, and the desired certification mark.

- Factory Inspection: BIS conducts an inspection of the manufacturer’s production facility to evaluate quality control processes, infrastructure, and adherence to relevant standards.

- Sample Testing: BIS collects samples of the product from the manufacturer for testing in authorized BIS laboratories or recognized testing centres. These tests assess various parameters specified by the BIS standard.

- Certification Decision: Based on satisfactory test results and compliance with standards, BIS decides whether to grant certification to the product. If approved, the manufacturer is issued a BIS certification license.

- Regular Monitoring: BIS monitors the manufacturing process of certified products through periodic audits and market surveillance to ensure ongoing compliance with quality control processes and standards.

OMEGA QMS PVT. LTD. – YOUR PARTNER FOR SUCCESS

In the journey to achieve BIS certification and maintain exceptional product quality, Omega QMS Pvt. Ltd. stands out as a valuable partner for manufacturers. With a global presence and a proven track record of successful collaborations with Fortune 500 companies, Omega QMS offers a comprehensive range of services tailored to streamline the certification process and ensure compliance with industry standards.

Expert Guidance: Omega provides access to a team of seasoned experts with extensive knowledge of regulatory requirements, industry best practices, and the intricacies of the certification process. These experts guide manufacturers through the complex landscape, offering insights and strategies to navigate the process efficiently.

Testing and Validation: Omega assists manufacturers in planning and executing necessary tests and validations required for BIS certification.

Documentation and Compliance: Achieving BIS certification demands meticulous documentation of processes, materials, and testing procedures. Omega supports manufacturers in creating comprehensive and accurate documentation aligned with BIS requirements, minimizing the risk of errors and rejections.

Inspection Support: Omega prepares manufacturers for BIS audits, ensuring they are well-prepared to address any issues that may arise and increase the likelihood of a successful outcome.

Customized Approach: Recognizing that each manufacturer’s journey toward BIS certification is unique, Omega tailors its services to fit specific needs, challenges, and goals, ensuring a personalized and effective approach.

Global Experience: With a presence in over 40 countries, Omega brings global experience to the table, offering insights into varying regulatory environments and industry practices, enabling manufacturers to excel globally.

Omega QMS Pvt. Ltd. serves as a strategic partner for manufacturers seeking BIS Certification for water meters and ferrules. Its comprehensive approach encompasses expert guidance, process control, testing and validation support, documentation assistance, audit preparation, training, and a global perspective. By collaborating with Omega, manufacturers gain a competitive edge in their pursuit of certification while upholding the highest standards of product quality and consumer satisfaction.

CONCLUSION

The BIS certification scheme for water meters (domestic type), water meters (bulk type), and ferrules for water services underscores the commitment to quality and reliability in the water supply industry. By adhering to the stringent requirements set forth in IS 779, IS 2373, and IS 2692 respectively, manufacturers demonstrate their dedication to producing products that meet the highest standards of performance and safety.

In this journey towards certification, organizations like Omega QMS PVT. Ltd. serve as valuable partners, guiding manufacturers through the complexities of quality certification processes. In essence, the BIS certification scheme, coupled with the support of organizations like Omega QMS Pvt. Ltd., not only elevates the quality and reliability of water meters and ferrules for water services but also contributes to the overarching goal of ensuring the efficient and sustainable management of water resources.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply