BIS CERTIFICATION FOR PRELAMINATED PARTICLE BOARDS FROM WOOD AND OTHER LIGNOCELLULOSIC MATERIAL AS PER IS 12823:2015

INTRODUCTION

Prelaminated particle boards play a crucial role in various construction and furniture applications due to their versatility, durability, and aesthetic appeal. These boards, conforming to the Indian Standard IS 12823, are manufactured through a meticulous process involving the lamination of particle boards with synthetic resin-impregnated papers or overlays. This standard ensures that prelaminated particle boards meet stringent quality requirements for both general and special purposes. In this article, we’ll delve into the specifics of IS 12823, its testing procedures, and the significance of certification schemes and quality management systems in ensuring adherence to standards. In the realm of manufacturing and quality assurance, ensuring adherence to standards and certifications is paramount. Organizations like Omega QMS Pvt. Ltd. and the Bureau of Indian Standards (BIS) play crucial roles in this regard.

IS 12823:2015 PRELAMINATED PARTICLE BOARDS FROM WOOD AND OTHER LIGNOCELLULOSIC MATERIAL

IS 12823 is an Indian Standard that outlines the requirements for prelaminated particle boards used in various applications, both general and specialized. The standard covers aspects such as materials, manufacturing processes, dimensions, testing procedures, and quality parameters. It specifies two grades (Grades I and II) and four types within each grade, categorized based on surface abrasion characteristics. Materials used in prelaminated particle boards, including particle boards, impregnated base papers, and overlays, are detailed, with specific requirements for their properties and compositions. Manufacturing processes involve heat and pressure lamination of particle boards with impregnated papers or overlays, ensuring a strong bond and high-quality finish. IS 12823 prescribes comprehensive testing protocols to assess the quality and performance of prelaminated particle boards. Tests include density, moisture content, water absorption, mechanical properties (such as modulus of rupture and tensile strength), surface characteristics (including abrasion resistance), and resistance to environmental factors like steam, cracks, cigarette burns, and stains.

IS 12823 is an Indian Standard that outlines the requirements for prelaminated particle boards used in various applications, both general and specialized. The standard covers aspects such as materials, manufacturing processes, dimensions, testing procedures, and quality parameters. It specifies two grades (Grades I and II) and four types within each grade, categorized based on surface abrasion characteristics. Materials used in prelaminated particle boards, including particle boards, impregnated base papers, and overlays, are detailed, with specific requirements for their properties and compositions. Manufacturing processes involve heat and pressure lamination of particle boards with impregnated papers or overlays, ensuring a strong bond and high-quality finish. IS 12823 prescribes comprehensive testing protocols to assess the quality and performance of prelaminated particle boards. Tests include density, moisture content, water absorption, mechanical properties (such as modulus of rupture and tensile strength), surface characteristics (including abrasion resistance), and resistance to environmental factors like steam, cracks, cigarette burns, and stains.

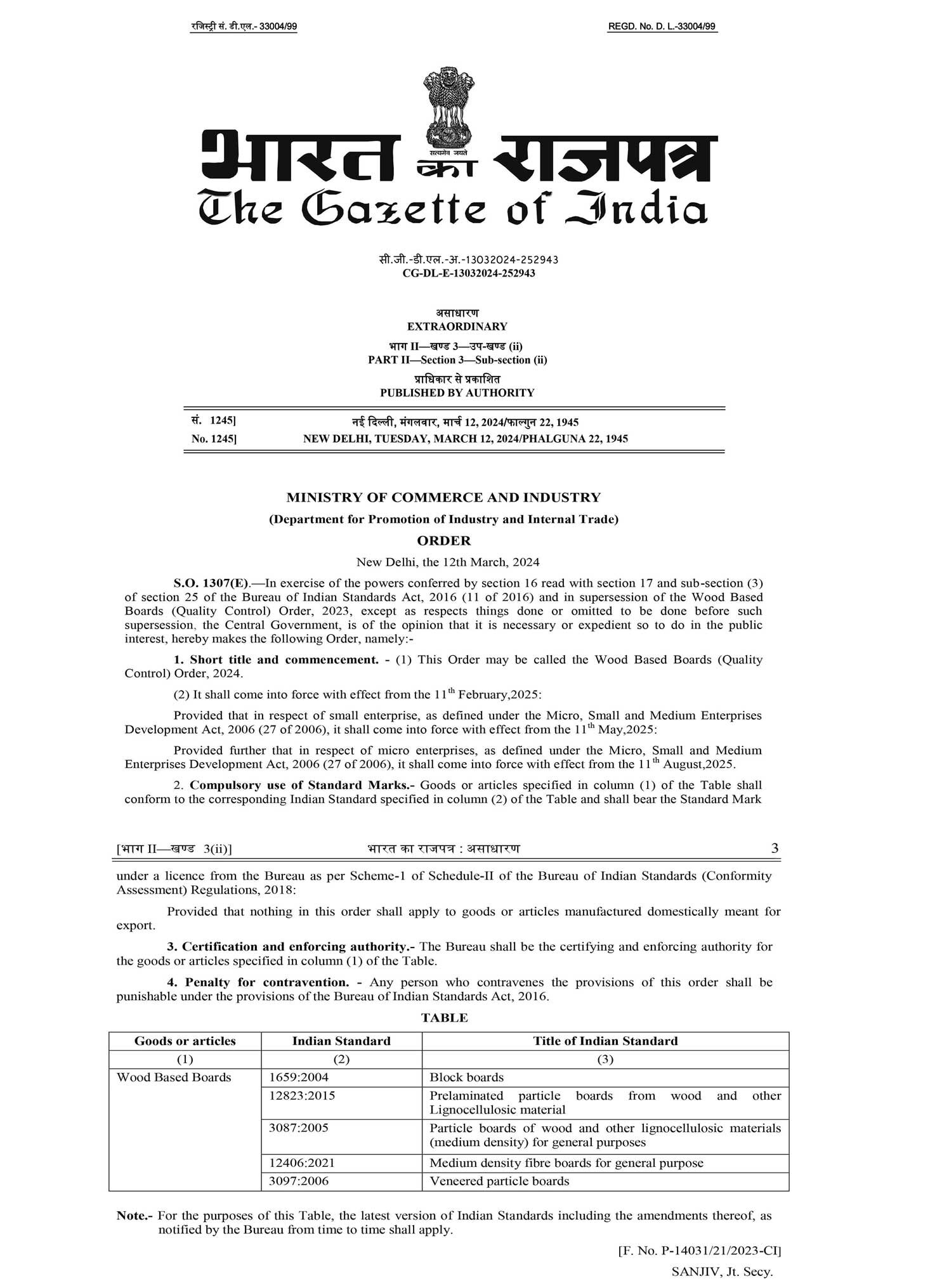

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 12 MARCH 2024 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for prelaminated particle boards as mentioned above to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark (ISI Mark ) of the Bureau of Indian Standards under a valid BIS license. In short, it has become obligatory for all the manufacturers of block boards, whether in India or overseas, to immediately apply for BIS license and obtain a valid BIS certification license before that the last date of implementation of the order, i.e., 11 February 2025.

BIS CERTIFICATION SCHEME FOR PRELAMINATED PARTICLE BOARDS

The Bureau of Indian Standards (BIS) is the national standards body of India responsible for developing and promoting quality benchmarks across various industries. BIS certification is a mark of quality and compliance with Indian standards, ensuring that products meet specified safety, reliability, and performance criteria. For prelaminated particle boards, adherence to IS 12823 is essential to obtain BIS certification, signifying conformity to established quality norms.

ROLE OF OMEGA QMS PVT. LTD

Omega QMS Pvt. Ltd. plays a pivotal role in facilitating BIS certification and ensuring compliance with IS 12823. As a quality management consultancy firm, Omega specializes in assisting businesses in implementing robust quality management systems aligned with relevant standards and regulatory requirements. Omega’s expertise in training, and audit services empowers manufacturers of prelaminated particle boards to streamline their processes, enhance product quality, and achieve BIS certification seamlessly. Omega QMS Pvt. Ltd. specializes in facilitating compliance with standards and regulatory requirements for businesses across various sectors. Omega’s expertise extends to guiding manufacturers through the intricacies of standards such as IS 12823, assisting them in achieving BIS certification, and enhancing their overall quality assurance practices. Omega’s collaboration with businesses seeking BIS certification streamlines the certification process, facilitates adherence to standards, and reinforces the credibility and marketability of certified products

CONCLUSION

In conclusion, IS 12823 serves as a benchmark for ensuring the quality, reliability, and performance of prelaminated particle boards in India. Compliance with this standard not only enhances product quality but also instills confidence among consumers, architects, and builders regarding the suitability and durability of these boards for diverse applications. BIS certification, facilitated by reputable quality management firms like Omega QMS Pvt. Ltd., underscores manufacturers’ commitment to excellence and adherence to established quality norms, thereby fostering trust and credibility in the market. In essence, adherence to IS 12823, coupled with BIS certification and effective quality management practices, reinforces the position of prelaminated particle boards as a preferred choice in the construction and furniture industries, offering a harmonious blend of functionality, aesthetics, and durability.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply