BIS CERTIFICATION OF ENDLESS V-BELTS FOR INDUSTRIAL PURPOSES PART 1 GENERAL PURPOSE, ENDLESS V-BELTS FOR INDUSTRIAL PURPOSES PART 2 FIRE RESISTANT AND ANTISTATIC V-BELTS AND ENDLESS NARROW V-BELTS FOR INDUSTRIAL USE AS PER IS 2494 (PART 1):1994, IS 2484 (PART 2):1993 AND IS 14261:1995

INTRODUCTION

In the intricate web of industrial machinery, the seamless transmission of power relies heavily on the efficiency and reliability of endless V-belts. To ensure these crucial components meet stringent quality standards, the Bureau of Indian Standards (BIS) has meticulously crafted a series of specifications, delineated in IS 2494 and is 14261. These standards provide a comprehensive framework covering various aspects such as dimensions, materials, workmanship, and transmission capacities of endless V-belts tailored for specific industrial applications. In the realm of industrial compliance, BIS certification stands as a hallmark of quality assurance and adherence to national standards. In this article, we delve into the intricacies of IS 2494 (Part 1), (Part 2), and IS 14261, shedding light on their significance, implications, and the role of BIS certification in upholding industry standards. Additionally, we explore how Omega QMS Pvt Ltd plays a pivotal role in assisting manufacturers in obtaining BIS certification for their endless V-belts, ultimately contributing to the seamless functioning of industrial machinery and the overall safety and reliability of industrial operations.

INDIAN STANDARDS

IS 2494 (PART 1) :1994 1 GENERAL PURPOSE

IS 2494 (Part 1) outlines the dimensions, materials, workmanship, and transmission capacities of endless V-belts used in general industrial applications. It mandates the use of elastomeric compounds with polyester reinforcement, coated with suitable compounds like polychloroprene. The standard emphasizes the importance of manufacturing belts free from defects such as lumps, sponginess, and loose fabric joints. It also provides guidelines for testing the reinforcement cord/fabric and the outer jacket of the V-belt to ensure quality and reliability. Cross-section dimensions and the nominal included angle of belts are specified in the standard, ensuring compatibility with pulley grooves. Designation of V-belts follows a prescribed format, incorporating standard pitch lengths and belt reference numbers. The standard further elaborates on belt pitch length and tolerances, recommending the use of standard belts for new installations and replacement purposes. Matched belts are recommended for multi-belt drives to prevent load imbalance, with a system of coding provided for ease of identification. Transmitting capacities of V-belts are outlined in annexes for the guidance of designers and users, ensuring proper selection and application in industrial drives.

IS 2494 (Part 1) outlines the dimensions, materials, workmanship, and transmission capacities of endless V-belts used in general industrial applications. It mandates the use of elastomeric compounds with polyester reinforcement, coated with suitable compounds like polychloroprene. The standard emphasizes the importance of manufacturing belts free from defects such as lumps, sponginess, and loose fabric joints. It also provides guidelines for testing the reinforcement cord/fabric and the outer jacket of the V-belt to ensure quality and reliability. Cross-section dimensions and the nominal included angle of belts are specified in the standard, ensuring compatibility with pulley grooves. Designation of V-belts follows a prescribed format, incorporating standard pitch lengths and belt reference numbers. The standard further elaborates on belt pitch length and tolerances, recommending the use of standard belts for new installations and replacement purposes. Matched belts are recommended for multi-belt drives to prevent load imbalance, with a system of coding provided for ease of identification. Transmitting capacities of V-belts are outlined in annexes for the guidance of designers and users, ensuring proper selection and application in industrial drives.

IS 2494 (PART 2): 1993 V-BELTS — ENDLESS V-BELTS FOR INDUSTRIAL PURPOSES PART 2 FIRE RESISTANT AND ANTISTATIC V-BELTS

IS 2494 (PART 2): 1993 V-BELTS — ENDLESS V-BELTS FOR INDUSTRIAL PURPOSES PART 2 FIRE RESISTANT AND ANTISTATIC V-BELTS

The BIS standard for fire resistant and antistatic V-belts (Part 2) encompasses requirements and testing methodologies to guarantee their performance in challenging conditions. The standard defines fire resistant V-belts as those incapable of propagating fire and antistatic V-belts as those able to dissipate static charges effectively. It outlines tests such as fire resistance and electrical resistance to assess compliance. For fire resistance, the standard specifies extinguishing time criteria for different V-belt cross sections. Additionally, it mandates tensile tests to ensure mechanical strength.

IS 14261:1995 V-BELTS – ENDLESS NARROW V-BELTS FOR INDUSTRIAL USE

IS 14261 for endless narrow V-belts encompasses specifications regarding dimensions, materials, workmanship, and transmission capacities. It defines the composition of V-belts, including elastomeric compounds, polyester reinforcement, and outer fabric coatings. Manufacturing processes must adhere to stringent quality control measures to ensure V-belts are free from defects. The standard also addresses cross-section dimensions, recommending nominal values while allowing slight variations to fit pulley grooves within specified limits. Additionally, it emphasizes the importance of matched belts in multi-belt drives to prevent load imbalance. Recommendations for coding V-belts and guidelines for transmitting capacities are also provided, aiding users in proper belt selection and application.

IS 14261 for endless narrow V-belts encompasses specifications regarding dimensions, materials, workmanship, and transmission capacities. It defines the composition of V-belts, including elastomeric compounds, polyester reinforcement, and outer fabric coatings. Manufacturing processes must adhere to stringent quality control measures to ensure V-belts are free from defects. The standard also addresses cross-section dimensions, recommending nominal values while allowing slight variations to fit pulley grooves within specified limits. Additionally, it emphasizes the importance of matched belts in multi-belt drives to prevent load imbalance. Recommendations for coding V-belts and guidelines for transmitting capacities are also provided, aiding users in proper belt selection and application.

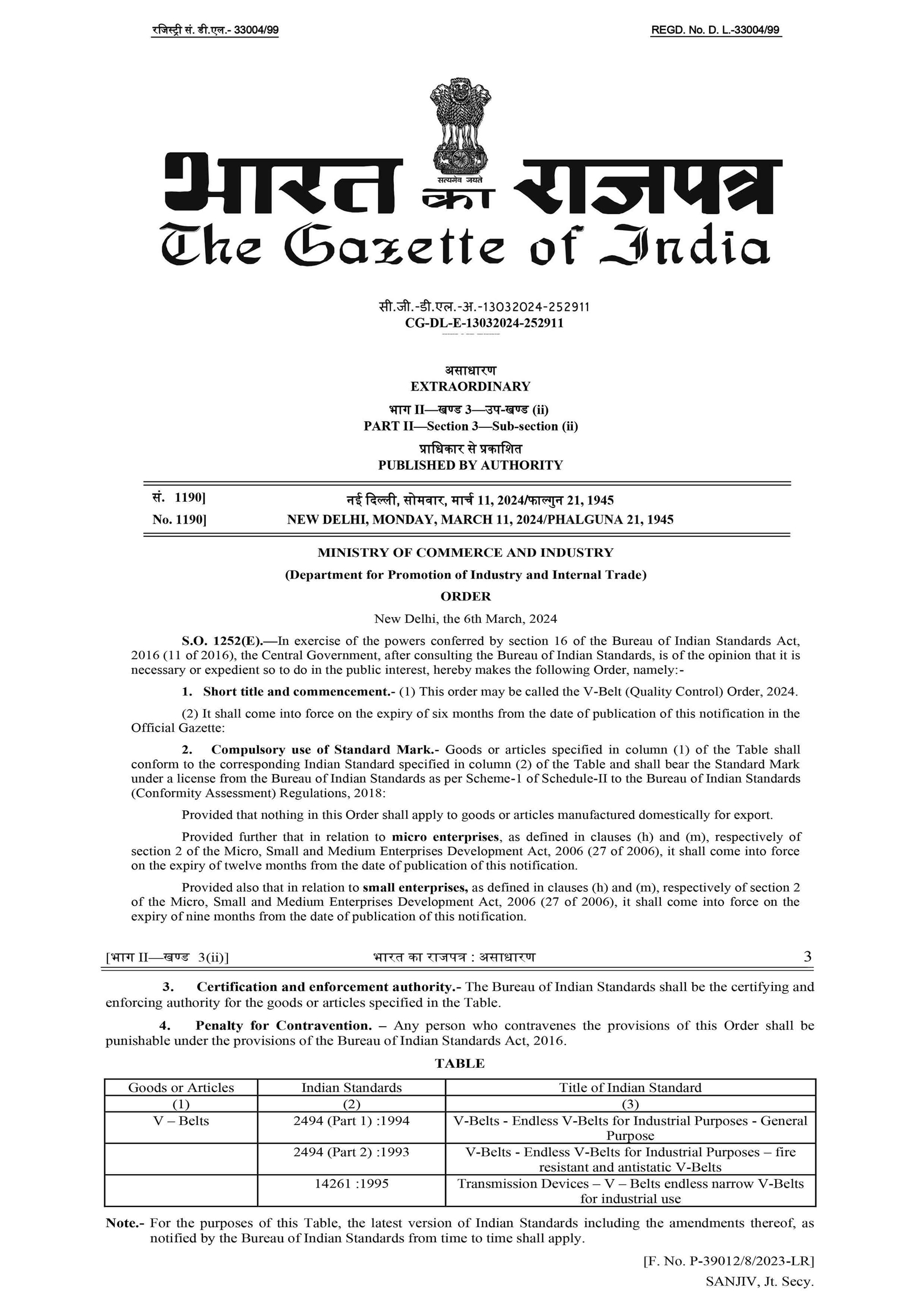

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 06 MARCH 2024 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for all V-Belts to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence. In short, it has become obligatory for all the manufacturers of V-Belts, whether in India or overseas, to immediately apply for BIS licence and obtain a valid BIS certification licence before that the last date of implementation of the order, i.e., 05 September 2024.

BIS CERTIFICATION SCHEME

The BIS Standards, IS 2494 and IS 14261, establish a comprehensive framework encompassing various quality parameters that V-Belts must adhere to. The Bureau of Indian Standards Certification Scheme is a vital framework established by the Indian government to ensure the quality, safety, and reliability of products available in the market. This scheme aims to safeguard consumer interests by setting stringent benchmarks and guidelines that products must meet before they can be deemed compliant. BIS certification covers a wide range of industries and products, encompassing the entire gamut of industrial and manufacturing activity. Various steps involved in the BIS Certification process are enumerated below:

- Standard Identification: Manufacturers identify the relevant BIS standard that applies to their chosen product category. These standards outline the specific quality, safety, and performance requirements that the product must meet.

- Application Submission: Manufacturers submit an application for BIS certification to the Bureau of Indian Standards (BIS), providing details about the product, its specifications, and the desired certification mark.

- Factory Inspection: BIS conducts an inspection of the manufacturer’s production facility to assess the quality control processes, infrastructure, and adherence to relevant standards.

- Sample Testing: BIS collects samples of the product from the manufacturer for testing in authorized BIS laboratories or recognized testing centers. These tests evaluate various parameters specified by the BIS standard.

- Certification Decision: Based on the satisfactory test results and compliance with standards, BIS decides whether to grant certification to the product. If approved, the manufacturer is issued a BIS certification license.

- Regular Monitoring: BIS monitors the manufacturing process of certified products through periodic audits and market surveillance to ensure ongoing compliance with quality control processes and standards.

OMEGA QMS PVT. LTD. – PARTNERING FOR SUCCESS

In the pursuit of achieving BIS certification and maintaining the highest levels of product quality, Omega QMS Pvt. Ltd. emerges as an invaluable partner for manufacturers. Backed by a global presence and a stellar track record of successful collaborations with Fortune 500 companies, Omega QMS provides an extensive array of services designed to streamline the certification process and ensure compliance with industry standards.

- Expert Guidance: Omega brings together a team of seasoned experts who possess in-depth knowledge of regulatory requirements, industry best practices, and intricacies of certification process. These experts guide manufacturers through the complex landscape, offering insights and strategies to navigate the process efficiently.

- Testing and Validation: Omega assists manufacturers in planning and executing necessary tests and validations required for BIS certification.

- Documentation and Compliance: The journey toward BIS certification demands meticulous documentation of processes, materials, and testing procedures. Omega aids manufacturers in creating comprehensive and accurate documentation that aligns with BIS requirements, reducing the risk of errors and rejections.

- Audit Support: Omega prepares manufacturers for BIS audits, which are a crucial part of the certification process. With its expertise, the organization ensures that manufacturers are well-prepared for audits, addressing any issues that may arise and increasing the likelihood of a successful outcome.

- Customized Approach: Each manufacturer’s journey toward BIS certification is unique. Omega understands this and tailors its services to fit the specific needs, challenges, and goals of individual manufacturers, ensuring a personalized and effective approach.

- Global Experience: With presence in over 40 countries, Omega brings global experience to the table. This international exposure allows the organization to offer insights into varying regulatory environments and industry practices, enabling manufacturers to excel globally.

Omega QMS Pvt. Ltd. functions as a strategic partner for manufacturers aiming to achieve BIS Certification. Its multifaceted approach encompasses expert guidance, process control, testing and validation support, documentation assistance, audit preparation, training, and a global perspective. By collaborating with Omega, manufacturers gain a competitive edge in their pursuit of certification while upholding the highest standards of product quality and consumer satisfaction.

For more details you can reach out to Omega at info@globalomega.com

CONCLUSION

In conclusion, the Indian Standards IS 2494 (Part 1), (Part 2), and (Part 2) play a pivotal role in ensuring the quality, reliability, and safety of endless V-belts used in industrial applications. These standards, meticulously crafted by the Bureau of Indian Standards (BIS), provide manufacturers, engineers, and users with comprehensive guidelines covering dimensions, materials, workmanship, transmission capacities, and selection procedures for endless V-belts.

As manufacturers strive to meet these stringent standards and obtain BIS certification, Omega QMS Pvt Ltd emerges as a beacon of support and expertise. By offering tailored assistance and guidance, Omega QMS Pvt Ltd aids manufacturers in navigating the complexities of the BIS certification scheme, ensuring compliance with national standards and fostering trust and reliability in the industrial sector.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Comment (1)

I enjoy what you guys are up too. This type of clever work and exposure!

Keep up the terrific works guys I’ve added you guys to blogroll.