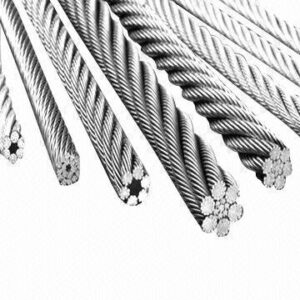

BIS Ceritifcation for an Array of Steel & Wire Ropes

Ensuring optimal quality and safety is of paramount importance in industries reliant on steel wire products, whose applications span from general engineering and mining to elevators and oil well drilling. Adhering to stringent certification standards is imperative to avert accidents, fortify performance, and preserve the integrity of industries. The Bureau of Indian Standards (BIS) has meticulously formulated exacting criteria for diverse steel wire products, including IS 2266, IS 2365, IS 1855, IS 1856, IS 2141, IS 4521, IS 6590, IS 278, and IS 16014. In this discourse, we delve into the profound significance of BIS certification for these products and elucidate how Omega QMS Pvt Ltd, a preeminent consultancy firm, can seamlessly navigate and facilitate the certification process.

IS 2266:2019 – Steel Wire Ropes for General Engineering Purpose

IS 2266:2019 delineates requisites for steel wire ropes employed in general engineering applications. Omega QMS Pvt Ltd ensures meticulous adherence to these standards, encompassing tensile strength, diameter, and corrosion resistance. Certification guarantees the safety and reliability of steel wire ropes, thus mitigating the potential risk of accidents and equipment failure.

IS 2266:2019 delineates requisites for steel wire ropes employed in general engineering applications. Omega QMS Pvt Ltd ensures meticulous adherence to these standards, encompassing tensile strength, diameter, and corrosion resistance. Certification guarantees the safety and reliability of steel wire ropes, thus mitigating the potential risk of accidents and equipment failure.

IS 2365:2018 – Steel Wire Suspension Ropes for Lifts, Elevators, and Hoists

Elevators and hoists necessitate an extra layer of scrutiny owing to the critical nature of their operations. IS 2365:2018 meticulously outlines standards for steel wire suspension ropes. BIS certification ensures unwavering adherence to stringent safety and performance standards, thus preemptively averting potential hazards associated with elevator failures.

Elevators and hoists necessitate an extra layer of scrutiny owing to the critical nature of their operations. IS 2365:2018 meticulously outlines standards for steel wire suspension ropes. BIS certification ensures unwavering adherence to stringent safety and performance standards, thus preemptively averting potential hazards associated with elevator failures.

IS 1855:2022 – Stranded Steel Wire Ropes for Winding and Man-Riding Haulages in Mines

Mines inherently pose multifaceted risks, accentuating the imperative for uncompromised safety standards. IS 1855:2022 establishes the gold standard for stranded steel wire ropes in mining applications. BIS certification not only vouchsafes durability and strength but also ensures the utmost safety in mining operations, thereby forestalling potential accidents.

Mines inherently pose multifaceted risks, accentuating the imperative for uncompromised safety standards. IS 1855:2022 establishes the gold standard for stranded steel wire ropes in mining applications. BIS certification not only vouchsafes durability and strength but also ensures the utmost safety in mining operations, thereby forestalling potential accidents.

IS 1856:2005 – Steel Wire Ropes for Haulage Purposes

Haulage operations in mines and construction sites hinge crucially on the reliability of steel wire ropes. IS 1856:2005 meticulously stipulates requirements for these ropes. BIS certification ensures an unassailable commitment to strength and durability standards, thereby enhancing safety and operational efficiency across diverse industries.

Haulage operations in mines and construction sites hinge crucially on the reliability of steel wire ropes. IS 1856:2005 meticulously stipulates requirements for these ropes. BIS certification ensures an unassailable commitment to strength and durability standards, thereby enhancing safety and operational efficiency across diverse industries.

IS 2141:2005 – Hot Dip Galvanized Stay Strand

Stability in structures is not a mere consideration but a categorical necessity. IS 2141:2005 articulates specifications for hot-dip galvanized stay strands. BIS certification meticulously attests to corrosion resistance and requisite tensile strength, underscoring the longevity and reliability of structures reliant on stay strands.

Stability in structures is not a mere consideration but a categorical necessity. IS 2141:2005 articulates specifications for hot-dip galvanized stay strands. BIS certification meticulously attests to corrosion resistance and requisite tensile strength, underscoring the longevity and reliability of structures reliant on stay strands.

IS 4521:2001 – Wire Ropes Used in Oil Wells and Oil Well Drilling

The exigencies of oil well drilling necessitate equipment of the highest order. IS 4521:2001 provides exacting specifications for wire ropes in oil wells. BIS certification ensures the utmost reliability under extreme conditions, thereby significantly mitigating the risk of accidents and equipment failure in the demanding oil and gas industry.

IS 6590:1972 – Braided Nylon Ropes for Mountaineering Purposes

The safety of mountaineers hinges profoundly on the quality of their equipment. IS 6590:1972 meticulously lays down requirements for braided nylon ropes. BIS certification unequivocally guarantees the strength and durability of these ropes, affording climbers the confidence needed to navigate the most challenging terrains.

IS 278:2009 – Galvanized Steel Barbed Wire for Fencing

Security, particularly in diverse settings such as agriculture, industry, and residential areas, is non-negotiable. IS 278:2009 elucidates the standards for galvanized steel barbed wire used in fencing. BIS certification meticulously ensures corrosion resistance and requisite strength, thus enhancing the security and longevity of fencing systems.

Security, particularly in diverse settings such as agriculture, industry, and residential areas, is non-negotiable. IS 278:2009 elucidates the standards for galvanized steel barbed wire used in fencing. BIS certification meticulously ensures corrosion resistance and requisite strength, thus enhancing the security and longevity of fencing systems.

IS 16014:2018 – Mechanically Woven, Double-Twisted, Hexagonal Wire Mesh Gabions, Revet Mattresses, and Rock Fall Netting

Civil engineering projects demand not just functionality but uncompromising reliability in wire mesh products. IS 16014:2018 meticulously delineates standards for various wire mesh products. BIS certification unequivocally assures the mechanical and corrosion resistance properties, rendering them eminently suitable for the rigors of civil engineering applications.

OMEGA QMS PVT. LTD.: Your Pinnacle Certification Partner

Obtaining BIS certification for steel wire products is an intricate process demanding scrupulous attention to standards and comprehensive documentation. Omega QMS Pvt Ltd, with its seasoned professionals, stands as a paragon in facilitating businesses through this intricate process with finesse.

Here’s how Omega QMS Pvt Ltd can elevate your certification journey:

Expert Guidance: With a cadre of seasoned professionals, Omega QMS Pvt Ltd offers sagacious guidance on the requisite steps and documentation necessary for certification.

Documentation Support: The consultancy goes beyond mere assistance, actively aiding in the preparation and meticulous organization of the extensive documentation indispensable for BIS standards compliance.

Compliance Assessment: Antecedent to the application, Omega QMS Pvt Ltd undertakes a meticulous assessment to ensure your products not only meet but exceed the relevant standards, deftly identifying areas for refinement.

Testing and Inspection: Collaborating with accredited laboratories, Omega QMS Pvt Ltd orchestrates the necessary battery of tests and inspections essential for certification.

Application Processing: Omega QMS Pvt Ltd is not just a facilitator but an active partner in completing and submitting the BIS certification application, ensuring unimpeachable accuracy and completeness.

Follow-Up and Support: Throughout the intricate certification process, Omega QMS Pvt Ltd remains a steadfast ally, providing unwavering support and addressing any queries or issues that may arise.

Certification Acquisition: When your products unequivocally meet the BIS standards, Omega QMS Pvt Ltd actively assists in obtaining BIS certification, bestowing upon you the imprimatur to market your products with unassailable confidence.

BIS certification for steel wire products is not merely a regulatory benchmark; it is a testament to an unwavering commitment to quality, safety, and industry-leading standards. In any industry, Omega QMS Pvt Ltd stands not just as a consultancy but as a beacon, guiding businesses through the complex terrain of BIS certification with consummate expertise and efficiency, reaffirming your commitment to excellence in the industry.

Leave a Reply