BIS CERTIFICATION OF CROSS RECESSED SCREWS

INTRODUCTION

Cross-recessed screws play a vital role in various industries, ensuring secure fastening in a wide range of applications. To maintain quality, reliability, and safety standards, adherence to technical specifications is essential. The Bureau of Indian Standards (BIS) provides a framework for ensuring the quality and performance of cross-recessed screws through certification standards such as IS 18471, IS 7483, IS 18507, and others. This article explores the importance of BIS certification for cross-recessed screws, its benefits, and the role of Omega QMS Pvt. Ltd in assisting manufacturers in obtaining BIS certification.

INDIAN STANDARDS

IS 18471 (PART 1):2023 FASTENERS – CROSS RECESSED DRILLING SCREWS WITH TAPPING SCREW THREAD PART 1 PAN HEAD

IS 18471 (Part 1):2023 specifies the technical requirements for cross recessed drilling screws with tapping screw thread, specifically detailing the Pan Head type. This includes specifications for the dimensions and tolerances of the screw’s various components such as the head diameter, head height, thread length, pitch, and thread form. Additionally, the standard outlines the permissible materials, surface finish, and hardness requirements for these screws to ensure adequate strength, corrosion resistance, and durability. It also provides guidelines for the testing methods to assess the screws’ mechanical properties, such as tensile strength, torsional strength, and hardness. Adherence to this standard ensures uniformity and reliability in the manufacturing and use of these screws across different applications.

IS 18471 (PART 2):2023 FASTENERS – CROSS RECESSED DRILLING SCREWS WITH TAPPING SCREW THREAD PART 2 COUNTERSUNK HEAD

IS 18471 (Part 2):2023 outlines the technical specifications for cross recessed drilling screws with tapping screw thread, specifically focusing on the Countersunk Head type. This standard provides detailed requirements for the dimensions, tolerances, materials, and performance characteristics of these screws.

Technical aspects covered in the standard include:

Dimensions and tolerances: Specifications for the head diameter, head height, thread length, pitch, and thread form are provided to ensure consistency and compatibility with corresponding components and tools.

Material requirements: Guidelines are given for the permissible materials used in the manufacturing of these screws, ensuring adequate strength, corrosion resistance, and durability based on the intended application.

Surface finish: Requirements for surface finish are specified to meet certain standards of appearance, corrosion resistance, and frictional properties.

Mechanical properties: Testing methods and criteria are outlined to assess the screws’ mechanical properties, such as tensile strength, torsional strength, and hardness, ensuring they meet the desired performance standards.

Compatibility and usability: The design of the cross recessed head ensures compatibility with corresponding tools for efficient installation, facilitating usability across various applications where secure fastening is essential.

IS 18471 (PART 3):2023 FASTENERS – CROSS RECESSED DRILLING SCREWS WITH TAPPING SCREW THREAD PART 3 RAISED COUNTERSUNK HEAD

IS 18471 (Part 3):2023 delineates the technical requirements for cross recessed drilling screws with tapping screw thread, focusing specifically on the Raised Countersunk Head type. This standard provides comprehensive specifications regarding the dimensions, tolerances, materials, and performance characteristics of these screws.

Key technical aspects addressed in the standard include:

Dimensional specifications: Detailed requirements are provided for the head diameter, head height, thread length, pitch, and thread form to ensure uniformity and compatibility with corresponding components and tools.

Material considerations: Guidelines are established for the permissible materials utilized in the production of these screws, emphasizing factors such as strength, corrosion resistance, and durability tailored to the intended application.

Surface finish criteria: Specifications for surface finish are outlined to meet desired standards of appearance, corrosion resistance, and frictional properties, ensuring optimal performance and longevity.

Mechanical properties assessment: The standard outlines testing methodologies and criteria to evaluate the mechanical properties of the screws, including tensile strength, torsional strength, and hardness, thereby ensuring they meet the required performance standards.

Usability and compatibility: The design of the cross recessed head is engineered to facilitate compatibility with corresponding tools for efficient installation, enhancing usability across various applications requiring secure fastening.

IS 18476:2023 FASTENERS – HEXAGON WASHER HEAD DRILLING SCREWS WITH TAPPING SCREW THREAD

IS 18476:2023 specifies the technical requirements for hexagon washer head drilling screws with tapping screw thread. Here’s a summary of the standard’s technical specifications:

Dimensional Requirements: Detailed specifications are provided for the dimensions and tolerances of the screws, including the diameter and height of the hexagon washer head, thread length, pitch, and thread form. These specifications ensure uniformity and compatibility with corresponding components and tools.

Material Specifications: Guidelines are outlined for the permissible materials used in manufacturing the screws, emphasizing factors such as strength, corrosion resistance, and durability suitable for the intended application.

Surface Finish Criteria: The standard defines requirements for surface finish to meet desired standards of appearance, corrosion resistance, and frictional properties, ensuring optimal performance and longevity.

Mechanical Properties Assessment: Testing methodologies and criteria are provided to evaluate the mechanical properties of the screws, such as tensile strength, torsional strength, and hardness, ensuring they meet required performance standards.

Usability and Compatibility: The design of the hexagon washer head is engineered for compatibility with corresponding tools for efficient installation, enhancing usability across various applications requiring secure fastening.

IS 18480 (PART 1):2023 CROSS RECESSED TAPPING SCREWS: PART 1 PAN HEAD

IS 18480 (Part 1):2023 specifies the technical requirements for cross recessed tapping screws with a Pan Head design. Here’s a summary of the standard’s technical specifications:

Dimensional Requirements: Detailed specifications are provided for the dimensions and tolerances of the screws, including the diameter and height of the pan head, thread length, pitch, and thread form. These specifications ensure uniformity and compatibility with corresponding components and tools.

Material Specifications: Guidelines are outlined for the permissible materials used in manufacturing the screws, emphasizing factors such as strength, corrosion resistance, and durability suitable for the intended application.

Surface Finish Criteria: The standard defines requirements for surface finish to meet desired standards of appearance, corrosion resistance, and frictional properties, ensuring optimal performance and longevity.

Mechanical Properties Assessment: Testing methodologies and criteria are provided to evaluate the mechanical properties of the screws, such as tensile strength, torsional strength, and hardness, ensuring they meet required performance standards.

Usability and Compatibility: The design of the cross recessed head is engineered for compatibility with corresponding tools for efficient installation, enhancing usability across various applications requiring secure fastening.

IS 18480 (PART 2):2023 CROSS RECESSED TAPPING SCREWS PART 2 COUNTERSUNK FLAT HEAD

IS 18480 (Part 2):2023 delineates the technical specifications for cross recessed tapping screws with a Countersunk Flat Head design. Here’s a summary of the standard’s technical specifications:

Dimensional Requirements: The standard provides detailed specifications for the dimensions and tolerances of the screws, including the diameter and height of the countersunk flat head, thread length, pitch, and thread form. These specifications ensure uniformity and compatibility with corresponding components and tools.

Material Specifications: Guidelines are outlined for the permissible materials used in manufacturing the screws, emphasizing factors such as strength, corrosion resistance, and durability tailored to the intended application.

Surface Finish Criteria: Requirements for surface finish are defined to meet desired standards of appearance, corrosion resistance, and frictional properties, ensuring optimal performance and longevity.

Mechanical Properties Assessment: The standard outlines testing methodologies and criteria to evaluate the mechanical properties of the screws, such as tensile strength, torsional strength, and hardness, ensuring they meet required performance standards.

Usability and Compatibility: The design of the cross recessed head is engineered for compatibility with corresponding tools for efficient installation, enhancing usability across various applications requiring secure fastening.

IS 18480 (PART 3):2023 CROSS RECESSED TAPPING SCREW PART 3 RAISED COUNTERSUNK OVAL HEAD

IS 18480 (Part 3):2023 specifies the technical requirements for cross recessed tapping screws with a Raised Countersunk Oval Head design. Here’s a summary of the standard’s technical specifications:

Dimensional Requirements: The standard provides detailed specifications for the dimensions and tolerances of the screws, including the diameter and height of the raised countersunk oval head, thread length, pitch, and thread form. These specifications ensure uniformity and compatibility with corresponding components and tools.

Material Specifications: Guidelines are outlined for the permissible materials used in manufacturing the screws, emphasizing factors such as strength, corrosion resistance, and durability tailored to the intended application.

Surface Finish Criteria: Requirements for surface finish are defined to meet desired standards of appearance, corrosion resistance, and frictional properties, ensuring optimal performance and longevity.

Mechanical Properties Assessment: The standard outlines testing methodologies and criteria to evaluate the mechanical properties of the screws, such as tensile strength, torsional strength, and hardness, ensuring they meet required performance standards.

Usability and Compatibility: The design of the cross recessed head is engineered for compatibility with corresponding tools for efficient installation, enhancing usability across various applications requiring secure fastening.

IS 7483:2018 PAN HEAD SCREWS WITH TYPE H OR TYPE Z CROSS RECESS – PRODUCT GRADE A

IS 7483:2018 specifies the technical requirements for Pan Head Screws with Type H or Type Z Cross Recess, classified under Product Grade A. Here’s a summary of the standard’s technical specifications:

Dimensional Requirements: The standard provides detailed specifications for the dimensions and tolerances of the screws, including the diameter and height of the pan head, thread length, pitch, and thread form. These specifications ensure uniformity and compatibility with corresponding components and tools.

Material Specifications: Guidelines are outlined for the permissible materials used in manufacturing the screws, emphasizing factors such as strength, corrosion resistance, and durability tailored to the intended application.

Surface Finish Criteria: Requirements for surface finish are defined to meet desired standards of appearance, corrosion resistance, and frictional properties, ensuring optimal performance and longevity.

Mechanical Properties Assessment: The standard outlines testing methodologies and criteria to evaluate the mechanical properties of the screws, such as tensile strength, torsional strength, and hardness, ensuring they meet required performance standards.

Product Grade A Classification: Classification under Product Grade A signifies screws with high-quality standards, meeting stringent requirements for precision and performance.

Usability and Compatibility: The design of the pan head screws with Type H or Type Z cross recess is engineered for compatibility with corresponding tools for efficient installation, enhancing usability across various applications requiring secure fastening.

IS 7485 (PART 1):2018 COUNTERSUNK FLAT HEAD SCREWS (COMMON HEAD STYLE) WITH TYPE H OR TYPE Z CROSS RECESS – PRODUCT GRADE A PART 1 STEEL SCREWS OF PROPERTY CLASS 4.8

IS 7485 (Part 1):2018 specifies the technical requirements for Countersunk Flat Head Screws with Type H or Type Z Cross Recess, categorized under Product Grade A. Here’s a summary of the standard’s technical specifications:

Dimensional Requirements: Detailed specifications are provided for the dimensions and tolerances of the screws, including the diameter and depth of the countersunk flat head, thread length, pitch, and thread form. These specifications ensure uniformity and compatibility with corresponding components and tools.

Material Specifications: Guidelines are outlined for the permissible materials used in manufacturing the screws, emphasizing factors such as strength, corrosion resistance, and durability, with a specific focus on steel screws of Property Class 4.8.

Surface Finish Criteria: Requirements for surface finish are defined to meet desired standards of appearance, corrosion resistance, and frictional properties, ensuring optimal performance and longevity, particularly for steel screws.

Mechanical Properties Assessment: The standard outlines testing methodologies and criteria to evaluate the mechanical properties of the screws, ensuring they meet the required performance standards for screws of Property Class 4.8, including tensile strength, yield strength, elongation, and hardness.

Product Grade A Classification: Classification under Product Grade A signifies screws with high-quality standards, meeting stringent requirements for precision and performance.

Usability and Compatibility: The design of the countersunk flat head screws with Type H or Type Z cross recess is engineered for compatibility with corresponding tools for efficient installation, enhancing usability across various applications requiring secure fastening.

IS 7485 (PART 2):2018 COUNTERSUNK FLAT HEAD SCREWS (COMMON HEAD STYLE) WITH TYPE H OR TYPE Z CROSS RECESS – PRODUCT GRADE A PART 2 STEEL SCREWS OF PROPERTY CLASS 8.8, STAINLESS STEEL SCREWS AND NON – FERROUS METAL SCREWS

IS 7485 (Part 2):2018 specifies the technical requirements for Countersunk Flat Head Screws with Type H or Type Z Cross Recess, classified under Product Grade A. Here’s a summary of the standard’s technical specifications:

Dimensional Requirements: Detailed specifications are provided for the dimensions and tolerances of the screws, including the diameter and depth of the countersunk flat head, thread length, pitch, and thread form. These specifications ensure uniformity and compatibility with corresponding components and tools.

Material Specifications: Guidelines are outlined for the permissible materials used in manufacturing the screws, including steel screws of Property Class 8.8, stainless steel screws, and non-ferrous metal screws. Emphasis is placed on factors such as strength, corrosion resistance, and durability, tailored to the specific material type.

Surface Finish Criteria: Requirements for surface finish are defined to meet desired standards of appearance, corrosion resistance, and frictional properties, ensuring optimal performance and longevity, particularly tailored to the material type used.

Mechanical Properties Assessment: The standard outlines testing methodologies and criteria to evaluate the mechanical properties of the screws, ensuring they meet the required performance standards for screws of Property Class 8.8, stainless steel screws, and non-ferrous metal screws, including tensile strength, yield strength, elongation, and hardness.

Product Grade A Classification: Classification under Product Grade A signifies screws with high-quality standards, meeting stringent requirements for precision and performance.

Usability and Compatibility: The design of the countersunk flat head screws with Type H or Type Z cross recess is engineered for compatibility with corresponding tools for efficient installation, enhancing usability across various applications requiring secure fastening.

IS 7486:2018 RAISED COUNTERSUNK HEAD SCREWS (COMMON HEAD STYLE) WITH TYPE H OR TYPE Z CROSS RECESS – PRODUCT GRADE A

IS 7486:2018 specifies the technical requirements for Raised Countersunk Head Screws with Type H or Type Z Cross Recess, classified under Product Grade A. Here’s a summary of the standard’s technical specifications:

Dimensional Requirements: Detailed specifications are provided for the dimensions and tolerances of the screws, including the diameter and height of the raised countersunk head, thread length, pitch, and thread form. These specifications ensure uniformity and compatibility with corresponding components and tools.

Material Specifications: Guidelines are outlined for the permissible materials used in manufacturing the screws, emphasizing factors such as strength, corrosion resistance, and durability, tailored to the intended application.

Surface Finish Criteria: Requirements for surface finish are defined to meet desired standards of appearance, corrosion resistance, and frictional properties, ensuring optimal performance and longevity.

Mechanical Properties Assessment: The standard outlines testing methodologies and criteria to evaluate the mechanical properties of the screws, ensuring they meet the required performance standards, including tensile strength, yield strength, elongation, and hardness.

Product Grade A Classification: Classification under Product Grade A signifies screws with high-quality standards, meeting stringent requirements for precision and performance.

Usability and Compatibility: The design of the raised countersunk head screws with Type H or Type Z cross recess is engineered for compatibility with corresponding tools for efficient installation, enhancing usability across various applications requiring secure fastening.

IS 18507:2024 DRYWALL SCREWS

IS 18507:2024 presumably specifies the technical requirements for drywall screws. Here’s a summary of the technical specifications that might be included:

Dimensional Requirements: Detailed specifications for the dimensions and tolerances of drywall screws, including length, diameter, thread pitch, and head type.

Material Specifications: Guidelines for the materials used in manufacturing drywall screws, focusing on factors such as strength, corrosion resistance, and suitability for use in drywall applications.

Thread Design: Specifications for the thread design, including the type of thread (e.g., fine thread, coarse thread) and the thread geometry optimized for secure attachment to drywall and studs.

Head Type: Requirements for the head type, such as bugle head or Phillips head, ensuring compatibility with corresponding tools for installation.

Coating or Finish: Specifications for any coatings or finishes applied to the screws to enhance corrosion resistance, improve aesthetics, or facilitate easier installation.

Performance Testing: Guidelines for testing the mechanical properties of drywall screws, including tensile strength, shear strength, and pull-out resistance, to ensure they meet required performance standards.

Packaging and Labeling: Requirements for packaging and labeling of drywall screws, including information about size, material, quantity, and any relevant standards compliance.

IS 18508:2024 CHIPBOARD SCREWS

IS 18508:2024 presumably specifies the technical requirements for chipboard screws. Here’s a summary of the technical specifications that might be included:

Dimensional Requirements: Detailed specifications for the dimensions and tolerances of chipboard screws, including length, diameter, thread pitch, and head type.

Material Specifications: Guidelines for the materials used in manufacturing chipboard screws, focusing on factors such as strength, corrosion resistance, and suitability for use in chipboard and other similar materials.

Thread Design: Specifications for the thread design, including the type of thread (e.g., fine thread, coarse thread) and the thread geometry optimized for secure attachment to chipboard and other materials.

Head Type: Requirements for the head type, such as countersunk head or pan head, ensuring compatibility with corresponding tools for installation.

Coating or Finish: Specifications for any coatings or finishes applied to the screws to enhance corrosion resistance, improve aesthetics, or facilitate easier installation.

Performance Testing: Guidelines for testing the mechanical properties of chipboard screws, including tensile strength, shear strength, and pull-out resistance, to ensure they meet required performance standards.

Packaging and Labeling: Requirements for packaging and labeling of chipboard screws, including information about size, material, quantity, and any relevant standards compliance.

IS 18509:2023 CROSS-RECESSED COUNTERSUNK HEAD WOOD SCREWS

IS 18509:2023 specifies the technical requirements for cross-recessed countersunk head wood screws. Here’s a summary of the standard’s technical specifications:

Dimensional Requirements: Detailed specifications for the dimensions and tolerances of the wood screws, including length, diameter, thread pitch, and head diameter and depth. These specifications ensure uniformity and compatibility with wood materials and corresponding tools.

Material Specifications: Guidelines for the materials used in manufacturing wood screws, focusing on factors such as strength, corrosion resistance, and suitability for use in wood applications. This may include specifications for different types of wood screws based on the material they are intended to be used with (e.g., hardwood, softwood).

Thread Design: Specifications for the thread design, including the type of thread (e.g., fine thread, coarse thread) and the thread geometry optimized for secure attachment to wood materials.

Head Type: Requirements for the head type, such as countersunk head or flat head, ensuring compatibility with corresponding tools for installation and achieving flush or recessed finishes.

Coating or Finish: Specifications for any coatings or finishes applied to the screws to enhance corrosion resistance, improve aesthetics, or facilitate easier installation in wood materials.

Performance Testing: Guidelines for testing the mechanical properties of wood screws, including tensile strength, shear strength, and pull-out resistance, to ensure they meet required performance standards for use in wood applications.

Packaging and Labeling: Requirements for packaging and labeling of wood screws, including information about size, material, quantity, and any relevant standards compliance.

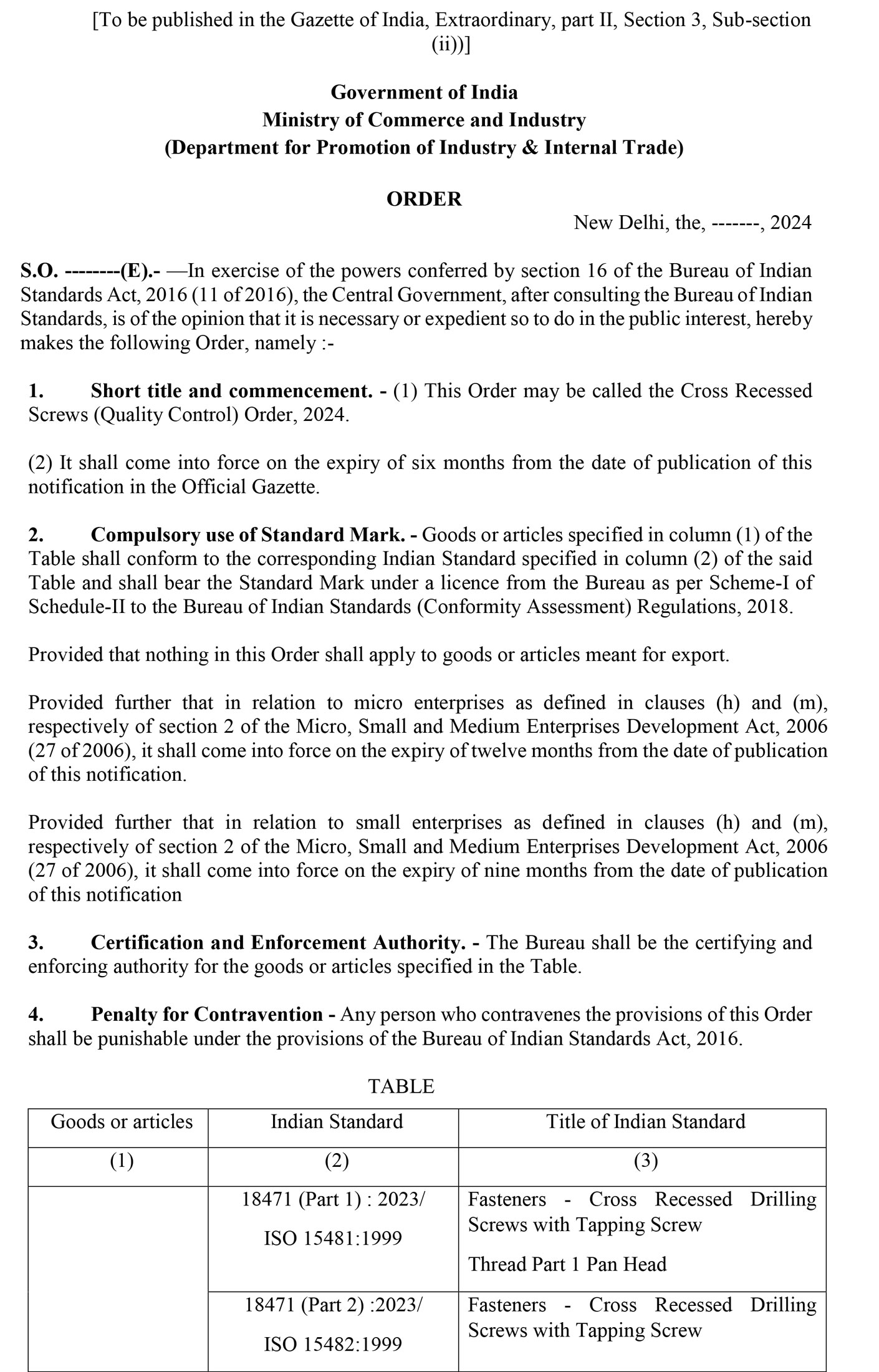

DRAFT QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued a draft Quality Control Order proposing to making it mandatory for all cross recessed screws as mentioned above to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence.

BIS CERTIFICATION MARKING

The BIS certification marking is a symbol of conformity with Indian standards and regulations. For cross recessed screws falling under above mentioned Indian Standards, the BIS certification mark indicates that the product has undergone rigorous testing and evaluation processes to ensure compliance with specified parameters. This mark instils trust and confidence among consumers, indicating that the screws meets the requisite quality standards and is suitable for its intended application. It also facilitates market access, both domestically and internationally, by signaling adherence to recognized standards.

OMEGA QMS PVT. LTD. – PARTNERING FOR SUCCESS

In the pursuit of BIS Certification and maintaining the highest product quality, Omega QMS Pvt. Ltd. emerges as an invaluable partner. With a global presence and a track record of successful collaborations, Omega QMS provides services to streamline the BIS certification process, ensuring compliance with IS 14493.

Expert Guidance: Omega’s seasoned experts guide manufacturers through the BIS certification process efficiently, ensuring alignment with relevant IS.

Testing and Validation: Assisting in planning and executing necessary tests and validations required for BIS certification as per relevant Indian standard.

Documentation and Compliance: Assisting in creating comprehensive and accurate documentation aligning with BIS requirements for communication cables

Inspection Support: Preparing manufacturers for BIS inspections/audits, ensuring preparedness and addressing any issues that may arise during the certification process.

Customized Approach: Tailoring services to fit the specific needs, challenges, and goals of individual manufacturers in the context of IS mentioned above.

Global Experience: Leveraging a presence in over 40 countries to offer insights into varying regulatory environments and industry practices, ensuring a comprehensive approach to BIS certification.

Omega QMS Pvt. Ltd. functions as a strategic partner for manufacturers seeking BIS Certification for cross recessed screws as per Indian Standards mentioned above. Its multifaceted approach encompasses expert guidance, process control, testing and validation support, documentation assistance, audit preparation, training, and a global perspective, providing a competitive edge while upholding the highest standards of product quality and consumer satisfaction.

CONCLUSION

BIS certification for cross-recessed screws is instrumental in ensuring quality, safety, and compliance with established standards. The ISI mark signifies adherence to stringent quality benchmarks, instilling confidence in consumers and stakeholders. Omega QMS Pvt. Ltd plays a pivotal role in assisting manufacturers in obtaining BIS certification, thereby enhancing their competitiveness, reputation, and market acceptance. By embracing BIS certification and partnering with Omega QMS, manufacturers can unlock opportunities for growth, innovation, and excellence in the manufacturing of cross-recessed screws.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply