BIS CERTIFICATION OF ADHESIVES FOR USE WITH CERAMIC, MOSAIC AND STONE TILES AS PER IS 15477:2019

INTRODUCTION

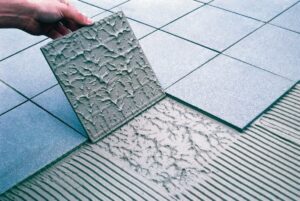

Adhesives play a crucial role in the installation of ceramic, mosaic, and stone tiles, ensuring their proper fixation and longevity. Recognizing this significance, the Bureau of Indian Standards (BIS) introduced IS 15477:2019 to set forth the requirements and classifications for these adhesives. This standard provides guidance on selecting the appropriate adhesive type based on factors like tile porosity, size, substrate, and application area, ensuring safe and effective tile installations.

IS 15477:2019 ADHESIVES FOR USE WITH CERAMIC, MOSAIC AND STONE TILES

IS 15477:2019 outlines five types of adhesives, each tailored to specific tile types, porosities, and installation conditions:

IS 15477:2019 outlines five types of adhesives, each tailored to specific tile types, porosities, and installation conditions:

Type 1 Adhesive: Suitable for tiles with apparent porosity greater than 3 percent, primarily for clay and non-vitrified ceramic tiles in interior dry areas.

Type 2 Adhesive: Designed for tiles with an apparent porosity less than or equal to 3 percent, including vitrified, glass mosaic, and large dimension tiles, suitable for both interior and exterior applications, especially in wet areas.

Type 3 Adhesive: Intended for exterior wall substrates, accommodating various tile types including ceramic, clay, basalt, and natural stone tiles.

Type 4 Adhesive: Suitable for drywall board substrates, offering versatility for installing tiles and stones on materials like gypsum boards, plywood, and fiber cement boards.

Type 5 Adhesive: Specifically formulated for tiles and engineered stones to be installed on metallic substrates or different cement-based substrates, featuring synthetic resin and mineral fillers for enhanced adhesion and durability.

Additionally, the standard specifies requirements for adhesion strength, open time, slip resistance, and deformability, ensuring the adhesives meet performance criteria for different applications. Adhesives are tested for tensile and shear adhesion strength, open time, slip, and deformability to ensure they meet the specified standards.

BIS CERTIFICATION SCHEME AT A GLANCE

The BIS Certification Scheme for IS 15477 is a vital framework established by the Indian government to ensure the quality, safety, and reliability of products available in the market. This scheme aims to safeguard consumer interests by setting stringent benchmarks and guidelines that products must meet before they can be deemed compliant. BIS certification covers a wide range of industries and products, encompassing the entire gamut of industrial and manufacturing activity. Various steps involved in the BIS Certification process are enumerated below:

- Standard Identification: Manufacturers identify the relevant BIS standard that applies to their chosen product category. These standards outline the specific quality, safety, and performance requirements that the product must meet.

- Application Submission: Manufacturers submit an application for BIS certification to the Bureau of Indian Standards (BIS), providing details about the product, its specifications, and the desired certification mark.

- Factory Inspection: BIS conducts an inspection of the manufacturer’s production facility to assess the quality control processes, infrastructure, and adherence to relevant standards.

- Sample Testing: BIS collects samples of the product from the manufacturer for testing in authorized BIS laboratories or recognized testing centers. These tests evaluate various parameters specified by the BIS standard.

- Certification Decision: Based on the satisfactory test results and compliance with standards, BIS decides whether to grant certification to the product. If approved, the manufacturer is issued a BIS certification license.

- Regular Monitoring: BIS monitors the manufacturing process of certified products through periodic audits and market surveillance to ensure ongoing compliance with quality control processes and standards.

OMEGA QMS PVT. LTD. – THE SOLUTION PROVIDER

Omega QMS Pvt Ltd boasts over two decades of unparalleled experience in providing regulatory compliance consultancy services to businesses across more than 40 countries. This extensive experience has enabled us to cultivate steadfast partnerships with esteemed Fortune 500 companies, reaffirming our commitment to delivering exceptional services that help our clients meet rigorous regulatory standards within their respective industries.

Central to our approach is the recognition that each client is unique, with specific needs and challenges. Our dedicated team works closely with clients, forging strong relationships and gaining a deep understanding of their operations, objectives, and regulatory requirements. This allows us to provide tailored solutions that not only ensure compliance but also drive efficiency, productivity, and ultimately, business growth.

We firmly believe that regulatory compliance goes beyond mere adherence to legal obligations; it is a fundamental aspect of ethical and responsible business conduct. By upholding the highest standards of integrity and diligence, we help organizations build trust with stakeholders, mitigate risks, and safeguard their reputation. Our aim is to empower clients to navigate complex regulatory landscapes with confidence and integrity, fostering a culture of compliance throughout their operations.

At Omega QMS Pvt Ltd, our mission extends beyond achieving compliance; it is about fostering a culture of excellence and accountability that drives sustainable success in today’s dynamic business environment. We are committed to staying abreast of evolving regulations and industry best practices, ensuring that our clients remain ahead of the curve. By leveraging our expertise and resources, we help organizations not only meet current regulatory requirements but also anticipate and prepare for future challenges.

Through our unwavering dedication to our clients’ success, we continue to set the benchmark for regulatory compliance consultancy worldwide. Our passion for excellence, combined with our proven track record of delivering results, makes us the trusted partner of choice for businesses seeking to navigate regulatory complexities with confidence and achieve their strategic objectives.

CONCLUSION

IS 15477:2019 serves as a comprehensive guide for selecting and using adhesives in tile installations, promoting safety, durability, and performance. By categorizing adhesives based on tile types, porosity, and application areas, the standard aids in the proper selection of adhesives, thereby enhancing the quality and longevity of tile installations. Adherence to this standard ensures that tile installations meet the necessary performance criteria, contributing to the overall reliability and safety of structures. As the construction industry continues to evolve, standards like IS 15477:2019 play a vital role in facilitating consistent and high-quality tile installations, ultimately benefiting both industry professionals and end-users. The BIS Certification of Adhesive as per IS 15477:2019 provides a framework for ensuring the quality, safety, and performance of adhesives used in tile installations. By obtaining a BIS license for Tile Adhesives as per IS 15477, manufacturers demonstrate their commitment to producing adhesive products that meet the highest standards of quality and reliability, instilling confidence in consumers and contributing to the overall integrity of the construction industry.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply