ENSURING QUALITY IN NICKEL PRODUCTION: A GUIDE TO BIS CERTIFICATION FOR REFINED NICKEL AS PER IS 2782 WITH OMEGA QMS PVT. LTD.

INTRODUCTION

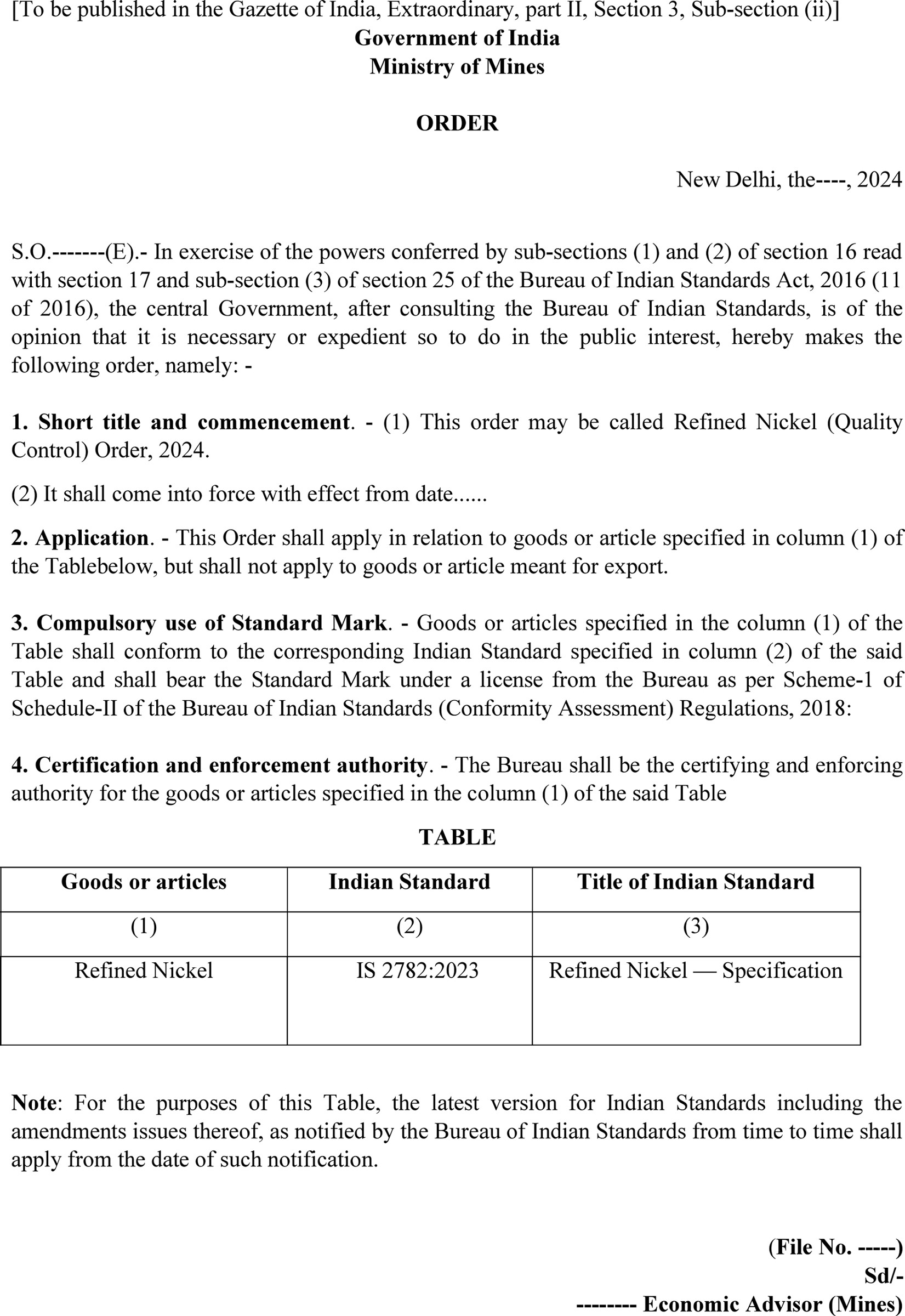

Refined nickel plays a crucial role in various industries, including aerospace, electronics, and manufacturing. Its demand for purity and consistent quality makes it essential to adhere to stringent standards, ensuring its performance and reliability. In India, the Bureau of Indian Standards (BIS) governs the certification process for refined nickel to ensure quality control and standardization across the sector. The Indian Standard IS 2782 specifies the quality and requirements for refined nickel, ensuring that only top-quality nickel reaches the market.

For manufacturers and suppliers looking to certify their refined nickel, obtaining BIS certification under IS 2782 is an indispensable step. The certification guarantees that the refined nickel meets the necessary safety and performance criteria, making it suitable for diverse applications. This article explores the significance of IS 2782, outlines the BIS certification process, and highlights how Omega QMS Pvt. Ltd. assists manufacturers in achieving seamless certification.

SUMMARY OF IS 2782: THE STANDARD FOR REFINED NICKEL

IS 2782, the Indian Standard for Refined Nickel, lays out the specifications, testing methodologies, and quality requirements for refined nickel produced or marketed in India. The standard ensures the chemical composition, purity, and physical properties of the refined nickel meet the required parameters. Key highlights of IS 2782 include:

Chemical Composition: IS 2782 specifies the permissible levels of various elements in refined nickel, ensuring its purity. The standard emphasizes the control of impurities such as sulfur, carbon, and iron to meet specific thresholds.

Grades : Refined nickel shall be of six grades, designated as, NR9995, NR9990, NR9982, NR9980, NR9960 and R9900 based on the minimum percentage of nickel in each grade

Physical Properties: The standard provides a detailed breakdown of the physical properties of refined nickel, such as density, tensile strength, and ductility, which are essential for its use in various applications.

Testing and Sampling Methods: The standard prescribes the procedures for sampling and testing refined nickel to confirm compliance with its chemical and physical property requirements. These methods ensure that the nickel is of consistent quality, with rigorous inspections at various stages of production.

This standard provides a reliable framework for nickel producers, allowing them to manufacture high-quality products suitable for demanding applications. For businesses seeking to penetrate the Indian market or secure customer trust, aligning with IS 2782 and obtaining BIS certification is crucial.

BIS CERTIFICATION OF REFINED NICKEL AS PER IS 2782

Achieving BIS certification under IS 2782 is a crucial step for manufacturers of refined nickel ingots. The certification ensures that the nickel produced complies with the highest quality standards, both in terms of chemical composition and physical properties. This certification acts as a mark of quality, increasing the product’s credibility and marketability, especially in regulated industries such as batteries and construction.

The BIS certification process involves several stages, each designed to rigorously evaluate the manufacturer’s compliance with IS 2782:

Application Submission: The process begins with the submission of a detailed application to BIS, where the manufacturer provides key information about the product, including the grade of nickel, the production process, and quality control measures in place.

Factory Inspection: BIS officials conduct a thorough inspection of the manufacturing facilities to ensure that the production processes meet the required standards. During the inspection, the BIS team assesses the manufacturing environment, raw material sources, and quality control systems to ensure consistent product quality.

Sample Testing: Samples of the nickel are then sent to BIS-authorized laboratories for testing. These samples undergo rigorous testing to confirm that their chemical composition and physical properties match the specifications outlined in IS 2782. The testing focuses on the purity levels, ensuring that the nickel meets the required grade and contains only the permissible levels of impurities.

Grant of Licence: Once the samples pass the tests and the factory inspection is complete, BIS grants the licence to the manufacturer. This licence allows the manufacturer to affix the BIS Standard Mark on their nickel ingots, signifying compliance with IS 2782.

For international manufacturers, additional steps such as nominating authorized Indian representatives and arranging performance bank guarantees are required. These steps ensure that overseas producers can also achieve BIS certification and comply with Indian standards.

OMEGA QMS PVT. LTD.: YOUR PARTNER IN BIS CERTIFICATION

Navigating the BIS certification process can be complex and time-consuming, especially for manufacturers unfamiliar with the procedures. This is where Omega QMS Pvt. Ltd. steps in. With over 30 years of experience in BIS regulations, Omega QMS provides comprehensive support throughout the certification process, ensuring that manufacturers can achieve compliance efficiently.

Services Provided by Omega QMS:

Application Assistance: Omega QMS guides manufacturers through the application submission process, ensuring all necessary details are correctly documented. By handling the paperwork and submission, Omega QMS minimizes the risk of application delays or rejections.

Factory Inspection Preparation: Preparing for a BIS inspection can be daunting. Omega QMS works closely with manufacturers to ensure their facilities meet the required standards. This includes setting up quality control systems and conducting mock audits to identify potential areas of improvement before the actual inspection.

Sample Testing Coordination: Omega QMS manages the submission of samples to BIS-accredited labs, ensuring that the testing process is smooth and efficient. They provide guidance on sample selection and ensure that the lead ingots submitted for testing meet the necessary quality standards.

Ongoing Compliance Support: BIS certification is not a one-time event. To maintain certification, manufacturers must undergo periodic audits and testing. Omega QMS offers ongoing support to ensure that manufacturers remain compliant with evolving regulations. This includes monitoring changes in BIS standards and helping clients update their production processes accordingly.

For international manufacturers, Omega QMS also assists with:

Nominating local representatives for BIS.

Signing necessary agreements with BIS.

Handling performance bank guarantees to meet financial compliance requirements.

BENEFITS OF PARTNERING WITH OMEGA QMS PVT. LTD.

Working with Omega QMS offers numerous benefits for manufacturers aiming to achieve BIS certification:

Expertise: With an experienced team well-versed in BIS regulations, Omega QMS ensures a smooth certification process.

Time and Cost Efficiency: By streamlining the certification process, Omega QMS helps manufacturers save both time and money.

Compliance Assurance: Omega QMS’s meticulous approach ensures that manufacturers meet all required standards, minimizing the risk of certification rejection.

Ongoing Support: With continuous assistance, Omega QMS helps manufacturers stay compliant with any changes in BIS regulations.

CONCLUSION AND FINAL THOUGHTS

BIS certification under IS 2782 is essential for manufacturers of refined nickel looking to establish themselves in the Indian market. It provides assurance to buyers and end-users that the nickel meets the highest quality standards and performs reliably in various industrial applications. However, navigating the certification process can be challenging without proper guidance.

This is where Omega QMS Pvt. Ltd. excels, offering manufacturers the expertise and support they need to successfully obtain BIS certification. With its in-depth knowledge of the certification process, Omega QMS ensures a seamless, efficient journey from application to certification, allowing manufacturers to focus on what they do best—producing high-quality refined nickel.

By aligning with IS 2782 and securing BIS certification, manufacturers demonstrate their commitment to quality and pave the way for long-term success in a highly competitive market.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply