BIS CERTIFICATION OF A.C. STATIC DIRECT CONNECTED WATTHOUR SMART METER CLASS 1 AND 2 A.C. STATIC TRANSFORMER OPERATED WATTHOUR AND VAR-HOUR SMART METERS, CLASS 0.2S, 0.5S AND 1.0S AS PER IS 16444 :2015 AND IS 16444(PART 2):2017

INTRODUCTION

In today’s dynamic energy landscape, accurate measurement and management of electrical energy consumption play a pivotal role in ensuring efficiency, sustainability, and cost-effectiveness. Recognizing this critical need, regulatory bodies and standards organizations have laid down comprehensive guidelines to govern the design, manufacturing, and deployment of smart meters. Among these, the Bureau of Indian Standards (BIS) has spearheaded the initiative to establish stringent benchmarks through standards such as IS 16444 and its subsequent parts.

In today’s dynamic energy landscape, accurate measurement and management of electrical energy consumption play a pivotal role in ensuring efficiency, sustainability, and cost-effectiveness. Recognizing this critical need, regulatory bodies and standards organizations have laid down comprehensive guidelines to govern the design, manufacturing, and deployment of smart meters. Among these, the Bureau of Indian Standards (BIS) has spearheaded the initiative to establish stringent benchmarks through standards such as IS 16444 and its subsequent parts.

In this article, we delve deeper into the nuances of IS 16444 and IS 16444 (Part 2), exploring their significance in the realm of energy measurement, and shedding light on the pivotal role played by Omega QMS Pvt Ltd in ensuring compliance and quality assurance in smart meter manufacturing.

INDIAN STANDARDS

IS 16444:2015 A.C. STATIC DIRECT CONNECTED WATTHOUR SMART METER CLASS 1 AND 2

Scope of the Standard : IS 16444:2015 delineates the specifications for static watt-hour smart meters designed to measure alternating current electrical active energy at a frequency of 50 Hz. It encompasses single-phase and three-phase systems, catering to both balanced and unbalanced loads. The standard covers type tests, routine tests, and acceptance tests, ensuring the accuracy and reliability of these meters.

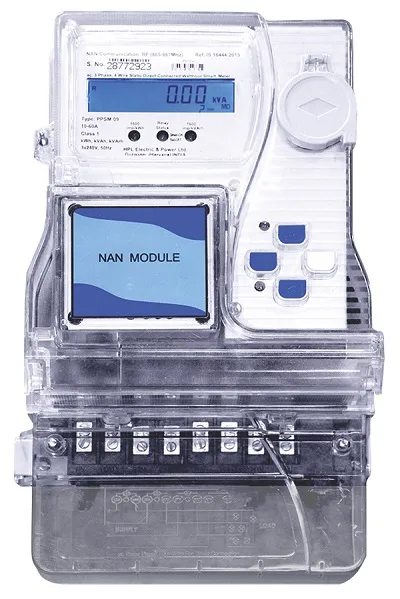

Smart Meter Architecture : The standard conceptualizes the smart meter as a single unit comprising four functional zones: metering, load switch, metering protocol, and communication modules.

Load Switch Requirement :Smart meters are equipped with load switching capabilities integral to the meter enclosure. These switches facilitate the control of electricity flow to the load, adhering to performance requirements specified in IS 15884.

Tests and Test Conditions : To ensure compliance, smart meters undergo various tests, including metrology tests, load switching capability tests, and tests for data exchange protocols. The standard prescribes the number of samples and criteria for conformity, ensuring consistency and reliability across smart meter deployments.

Smart Meter Functional Requirements IS 16444:2015 outlines functional requirements such as disconnection and reconnection mechanisms, event logging, and responsiveness to utility commands. It emphasizes the importance of status indication and communication with HES for seamless energy management.

IS 16444 (PART2 ):2017 A.C. STATIC TRANSFORMER OPERATED WATTHOUR AND VAR-HOUR SMART METERS, CLASS 0.2S, 0.5S AND 1.0S

The standard IS 16444 (Part 2) : 2017 outlines the specifications for AC static transformer-operated watthour and var-hour smart meters of accuracy classes 0.2S, 0.5S, and 1.0S. It applies to single-phase and three-phase balanced and unbalanced loads within a frequency range of 50 Hz. The standard covers type tests, routine tests, and acceptance tests for these meters. Key provisions of the standard include:

The standard IS 16444 (Part 2) : 2017 outlines the specifications for AC static transformer-operated watthour and var-hour smart meters of accuracy classes 0.2S, 0.5S, and 1.0S. It applies to single-phase and three-phase balanced and unbalanced loads within a frequency range of 50 Hz. The standard covers type tests, routine tests, and acceptance tests for these meters. Key provisions of the standard include:

Scope: Covers transformer-operated static watthour and var-hour meters with measuring elements, registers, operation indicators, and test outputs enclosed within the meter case. It also applies to multirate tariff meters and meters measuring energy in both directions.

Smart Meter Architecture: Defines functional zones including metering, data exchange, communication protocols, and communication modules. Provides flexibility in choosing desired features based on system objectives and site conditions.

Metering Requirements: Specifies metering and metrology requirements according to IS 14697, including classification, ratings, general constructional requirements, clearance and creepage distances, resistance to heat and fire, mechanical requirements, display of values, output device, marking of smart meter, climatic conditions, and electrical requirements.

Data Exchange Protocol: Adopts IS 15959 (Part 1) for data exchange protocol with specific requirements for smart meters. The protocol primarily utilizes DLMS/COSEM.

Communication Requirement: Mandates the use of either NAN or WAN module for communication with DCU or HES, and optionally an IHD. Specifies connectivity technologies, RF technology requirements, and communication layer protocol.

Tests and Test Conditions: Describes type tests, routine tests, and acceptance tests for metrology, data exchange protocol, and smart meter communicability. Specifies the number of samples and criteria for conformity.

Smart Meter Functional Requirements: Requires smart meters to respond to meter readings on demand, scheduled meter reading, remote firmware upgrade, and programming requests from HES. Additionally, smart meters must detect “First breath” (power on) and “Last gasp” (power off) conditions and communicate them to HES.

Overall, the standard aims to ensure the accuracy, reliability, and interoperability of AC static transformer-operated watthour and var-hour smart meters for various energy measurement applications.

QUALITY ASSURANCE FRAMEWORKS: GOVERNMENTAL APPROACH

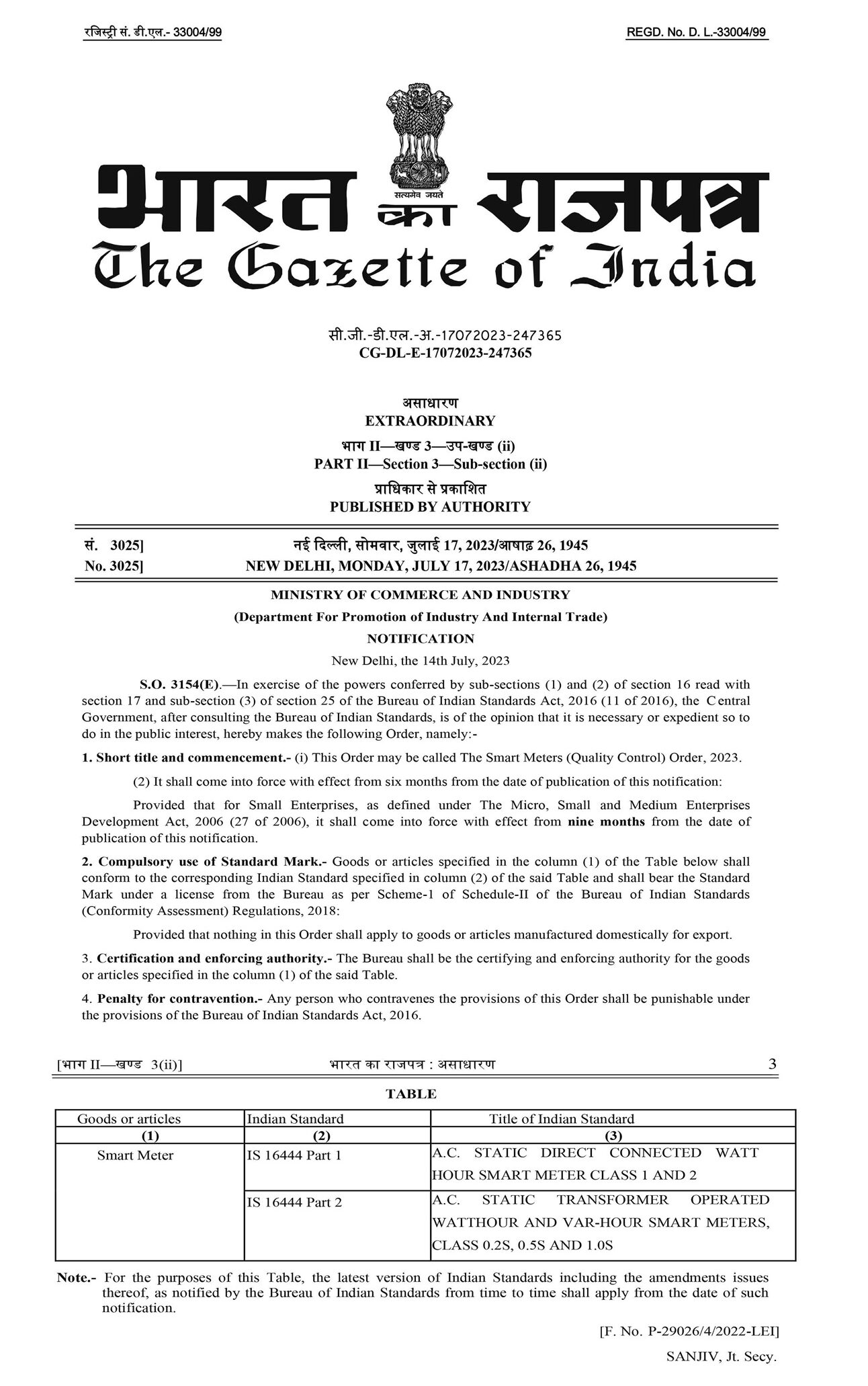

The Govt. of India periodically updates the Quality Control Orders (QCO), expanding its coverage to include more and more products. Recently, Govt. of India has included smart energy meters as per IS 16444 in the ambit of QCO for smart meters. One of the most significant provisions of this order is that the product imported into India must have a BIS Certification of Smart Meters as per IS 16444.

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 23 JULY 2023 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for smart energy meters to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark (ISI Mark) of the Bureau of Indian Standards under a valid BIS licence.

BIS CERTIFICATION SCHEME OF SMART ENERGY METERS AS PER IS 16444 AT A GLANCE

The BIS Certification Scheme is a vital framework established by the Indian government to ensure the quality, safety, and reliability of products available in the market. This scheme aims to safeguard consumer interests by setting stringent benchmarks and guidelines that products must meet before they can be deemed compliant. BIS certification covers a wide range of industries and products, encompassing the entire gamut of industrial and manufacturing activity. Various steps involved in the BIS Certification process are enumerated below:

Standard Identification: Manufacturers identify the relevant BIS standard (IS 16444 in this case) that applies to their chosen product category. These standards outline the specific quality, safety, and performance requirements that the product must meet.

Application Submission: Manufacturers submit an application for BIS certification to the Bureau of Indian Standards (BIS), providing details about the product, its specifications, and the desired certification mark.

Factory Inspection: BIS conducts an inspection of the manufacturer’s production facility to assess the quality control processes, infrastructure, and adherence to relevant standards.

Sample Testing: BIS collects samples of the product from the manufacturer for testing in authorized BIS laboratories or recognized testing centers. These tests evaluate various parameters specified by the BIS standard.

Certification Decision: Based on the satisfactory test results and compliance with standards, BIS decides whether to grant certification to the product. If approved, the manufacturer is issued a BIS certification license.

Regular Monitoring: BIS monitors the manufacturing process of certified products through periodic audits and market surveillance to ensure ongoing compliance with quality control processes and standards.

OMEGA QMS PVT. LTD. – PARTNERING FOR SUCCESS

In the pursuit of achieving BIS certification and maintaining the highest levels of product quality, Omega QMS Pvt. Ltd. emerges as an invaluable partner for manufacturers. Backed by a global presence and a stellar track record of successful collaborations with Fortune 500 companies, Omega QMS provides an extensive array of services designed to streamline the certification process and ensure compliance with industry standards.

Expert Guidance: Omega brings together a team of seasoned experts who possess in-depth knowledge of regulatory requirements, industry best practices, and intricacies of the certification process. These experts guide manufacturers through the complex landscape, offering insights and strategies to navigate the process efficiently.

Testing and Validation: Omega assists manufacturers in planning and executing necessary tests and validations required for BIS certification.

Documentation and Compliance: The journey toward BIS certification demands meticulous documentation of processes, materials, and testing procedures. Omega aids manufacturers in creating comprehensive and accurate documentation that aligns with BIS requirements, reducing the risk of errors and rejections.

Audit Support: Omega prepares manufacturers for BIS audits, which are a crucial part of the certification process. With its expertise, the organization ensures that manufacturers are well-prepared for audits, addressing any issues that may arise and increasing the likelihood of a successful outcome.

Customized Approach: Each manufacturer’s journey toward BIS certification is unique. Omega understands this and tailors its services to fit the specific needs, challenges, and goals of individual manufacturers, ensuring a personalized and effective approach.

Global Experience: With a presence in over 40 countries, Omega brings global experience to the table. This international exposure allows the organization to offer insights into varying regulatory environments and industry practices, enabling manufacturers to excel globally.

Omega QMS Pvt. Ltd. functions as a strategic partner for manufacturers aiming to achieve BIS Certification of Castings as per IS 210. Its multifaceted approach encompasses expert guidance, process control, testing and validation support, documentation assistance, audit preparation, training, and a global perspective. By collaborating with Omega, manufacturers gain a competitive edge in their pursuit of certification while upholding the highest standards of product quality and consumer satisfaction.

CONCLUSION

In conclusion, adherence to standards such as IS 16444 and IS 16444 (Part 2) is essential for ensuring accuracy and reliability in energy measurement devices, particularly smart meters. These standards, established by the Bureau of Indian Standards (BIS), provide comprehensive guidelines for the design, testing, and certification of smart meters, ensuring their performance in diverse operational conditions.

Omega QMS Pvt Ltd plays a crucial role in this ecosystem by offering specialized quality solutions tailored to the needs of smart meter manufacturers. Through their expertise in certification processes and quality assurance protocols, Omega QMS Pvt Ltd facilitates compliance with BIS standards, enabling manufacturers to deliver products of exceptional quality and reliability to consumers.

As the energy sector continues to evolve, adherence to stringent standards like IS 16444 becomes increasingly important. By upholding these standards, manufacturers can ensure the accuracy and reliability of smart meters, contributing to the efficiency and sustainability of energy systems.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply