BIS Certification for Hinges as per IS 1341:2018, IS 205:1992, IS 206 :2010, IS 362 :1991, IS 3818:1992, IS 3843:1995, IS 453 :1993 AND IS 18297:2023

In the world of construction and hardware, hinges play a pivotal role in ensuring the functionality and durability of doors, windows, cabinets, and other essential fixtures. To guarantee that these hinges meet specific quality standards, the Bureau of Indian Standards (BIS) has established certification protocols for various types of hinges. In this article, we delve into the significance of BIS certification for a range of hinges, including stainless steel butt hinges, steel butt hinges, non-ferrous metal butt hinges, tee and strap hinges, parliament hinges, continuous (piano) hinges, steel back flap hinges, double-acting spring hinges, and cabinet hinges, as per the relevant Indian Standards.

INDIAN STANDARDS

IS 12817:2020 STAINLESS STEEL BUTT HINGES

This standard covers types and requirements for materials, dimensions, manufacture and finish of stainless steel butt hinges. The stainless steel for flap shall conform to any grade mentioned in IS 6911. The stainless steel for pin shall conform to any grade mentioned in IS 6528. Besides dimensions number of holes and position of holes have been specified in the standard.

This standard covers types and requirements for materials, dimensions, manufacture and finish of stainless steel butt hinges. The stainless steel for flap shall conform to any grade mentioned in IS 6911. The stainless steel for pin shall conform to any grade mentioned in IS 6528. Besides dimensions number of holes and position of holes have been specified in the standard.

IS 1341:2018 STEEL BUTT HINGES

This standard lays down the requirements for materials, dimensions, manufacture and finish of steel butt hinges. Steel butt hinges shall be of the following types: a) Light weight ‘LW’ steel butt hinges b) Light weight ‘LWU’ unequal flap hinges c) Medium weight ‘MWU’ unequal flap hinges d) Medium weight ‘MW’ steel butt hinges e) Broad type ‘BR’ steel butt hinges f) Square type ‘SQ’ steel butt hinges g) Heavy weight (Type 1) ‘HW1’ steel butt hinges h) Heavy weight (Type 2) ‘HW2’ steel butt hinges

This standard lays down the requirements for materials, dimensions, manufacture and finish of steel butt hinges. Steel butt hinges shall be of the following types: a) Light weight ‘LW’ steel butt hinges b) Light weight ‘LWU’ unequal flap hinges c) Medium weight ‘MWU’ unequal flap hinges d) Medium weight ‘MW’ steel butt hinges e) Broad type ‘BR’ steel butt hinges f) Square type ‘SQ’ steel butt hinges g) Heavy weight (Type 1) ‘HW1’ steel butt hinges h) Heavy weight (Type 2) ‘HW2’ steel butt hinges

IS 205:1992 NON-FERROUS METAL BUTT HINGES

This standard lays down requirements for butt hinges made from non-ferrous metals. Butt hinges shall be of the following four types according to the material used: a) Extruded aluminum alloy butt hinges, b) Extruded brass butt hinges, c) Cast brass butt hinges, and d) Sheet brass butt hinges. The hinge pin shall be made of mild steel or brass or stainless steel, in the case of brass hinges. It may also be made of phosphor bronze, if so required by the purchaser. The hinge pin shall be of aluminum alloy or mild steel (galvanized ) or stainless steel in case of aluminum alloy hinges. The aluminum alloy hinge pin shall be hard anodized to a minimum thickness of 0.015 mm and sealed with oil, wax or lanolin. All screw holes shall be countersunk. The screw holes shall be suitable for countersunk head wood screws conforming to IS 6760:1972

This standard lays down requirements for butt hinges made from non-ferrous metals. Butt hinges shall be of the following four types according to the material used: a) Extruded aluminum alloy butt hinges, b) Extruded brass butt hinges, c) Cast brass butt hinges, and d) Sheet brass butt hinges. The hinge pin shall be made of mild steel or brass or stainless steel, in the case of brass hinges. It may also be made of phosphor bronze, if so required by the purchaser. The hinge pin shall be of aluminum alloy or mild steel (galvanized ) or stainless steel in case of aluminum alloy hinges. The aluminum alloy hinge pin shall be hard anodized to a minimum thickness of 0.015 mm and sealed with oil, wax or lanolin. All screw holes shall be countersunk. The screw holes shall be suitable for countersunk head wood screws conforming to IS 6760:1972

IS 206 :2010 TEE AND STRAP HINGES

Tee hinges are used in garden or big wooden plank doors, whereas strap hinges are used in boxes to strengthen their corners, in addition to big wooden gate doors. This standard lays down requirements for mild steel tee and strap hinges that are commonly used in general building construction. Light weight (Type 1) 2 Light weight (Type 2) 3 Medium weight (Type 1) 4 Medium weight (Type 2) 5 Heavy weight (Type 1) 6 Heavy weight (Type 2) 7 Heavy weight (Type 3). Tee and strap hinges shall be either bright finished or stove enameled black, as specified by the purchaser

Tee hinges are used in garden or big wooden plank doors, whereas strap hinges are used in boxes to strengthen their corners, in addition to big wooden gate doors. This standard lays down requirements for mild steel tee and strap hinges that are commonly used in general building construction. Light weight (Type 1) 2 Light weight (Type 2) 3 Medium weight (Type 1) 4 Medium weight (Type 2) 5 Heavy weight (Type 1) 6 Heavy weight (Type 2) 7 Heavy weight (Type 3). Tee and strap hinges shall be either bright finished or stove enameled black, as specified by the purchaser

IS 362 :1991 PARLIAMENT HINGES

This standard lays down the requirements regarding materials, manufacture, finish, marking and packing of parliament hinges. Parliament hinges shall be of the following three types: Type 1 Cast Type 2 Pressed Type 3 Fabricated. Materials for different types of parliament hinges shall be as follows: Type 1 Cast Brass Type 2 Mild Steel, Aluminum Alloy Type 3 Extruded Aluminum Alloy. The sides of the knuckle shall be straight and at right angles to the flap. The movement of the hinges shall be free, easy and square and shall not have any play or shake. Washer shall be provided between the knuckles for Type 1 and Type 3 binges. The washer shall be of the same diameter as the butt and shall be made of nylon, plastic or any other suitable material.

This standard lays down the requirements regarding materials, manufacture, finish, marking and packing of parliament hinges. Parliament hinges shall be of the following three types: Type 1 Cast Type 2 Pressed Type 3 Fabricated. Materials for different types of parliament hinges shall be as follows: Type 1 Cast Brass Type 2 Mild Steel, Aluminum Alloy Type 3 Extruded Aluminum Alloy. The sides of the knuckle shall be straight and at right angles to the flap. The movement of the hinges shall be free, easy and square and shall not have any play or shake. Washer shall be provided between the knuckles for Type 1 and Type 3 binges. The washer shall be of the same diameter as the butt and shall be made of nylon, plastic or any other suitable material.

IS 3818:1992 CONTINUOUS (PIANO) HINGES

This standard Jays down the requirements for continuous ( piano ) hinges. The sides of the-knuckles shall be straight and at right angle to the flap. The movement of hinge shall be free and easy and working shall not have any play or shake. All screw holes shall be clean and countersunk suitably for screws conforming to IS 6760 : 1972. Mild steel hinges shall be protected with anti corrosive treatment, such as bright polished, chromium plated or oxidized finish. Aluminum hinges shall be anodized and the quality of anodized finish shall not be less than that of Grade AC 10 of IS 1868 : 1982

This standard Jays down the requirements for continuous ( piano ) hinges. The sides of the-knuckles shall be straight and at right angle to the flap. The movement of hinge shall be free and easy and working shall not have any play or shake. All screw holes shall be clean and countersunk suitably for screws conforming to IS 6760 : 1972. Mild steel hinges shall be protected with anti corrosive treatment, such as bright polished, chromium plated or oxidized finish. Aluminum hinges shall be anodized and the quality of anodized finish shall not be less than that of Grade AC 10 of IS 1868 : 1982

IS 3843:1995 STEEL BACK FLAP HINGES

This standard covers types and the requirements regarding materials, dimensions, manufacture and finish of steel back flap hinges. Steel back flap hinges shall be of the following two types : a) Light weight hinges and b) Heavy weight hinges. Back flap hinges shall be well made and shall be tree from flaws and defects of any kind. All hinges shall be cut clean and square and shall be provided with mild steel hinge pins. The hole for the hinge pin shall be central and square to the knuckles. All sharp edges and corners shall be removed. The sides of knuckles shall be straight, at right angle and shall flush with the flap. The movement of the hinges shall be free and easy, and working shall not have any play or shake. Unless specified otherwise, the hinges shall be oxidized or finished bright with smooth and rust free surface.

This standard covers types and the requirements regarding materials, dimensions, manufacture and finish of steel back flap hinges. Steel back flap hinges shall be of the following two types : a) Light weight hinges and b) Heavy weight hinges. Back flap hinges shall be well made and shall be tree from flaws and defects of any kind. All hinges shall be cut clean and square and shall be provided with mild steel hinge pins. The hole for the hinge pin shall be central and square to the knuckles. All sharp edges and corners shall be removed. The sides of knuckles shall be straight, at right angle and shall flush with the flap. The movement of the hinges shall be free and easy, and working shall not have any play or shake. Unless specified otherwise, the hinges shall be oxidized or finished bright with smooth and rust free surface.

IS 453 :1993 DOUBLE-ACTING SPRING HINGES

This standard lays down the requirements for material, dimensions manufacture, finish and tests of doule-acting spring hinges and corresponding blank hinges used generally for swing doors. Double-acting spring hinges shall be of the following two types according to the material used : a) Mild steel double-acting spring hinges, and b) Brass double-acting spring hinges. Mild steel sheets and plates used in the manufacture of mild steel double-acting spring hinges shall conform to Grade 0 of IS 1079 : 1989 and shall satisfy the following bend test: ‘Suitable test pieces when cold, shall withstand without fracture, being doubled over, either by pressure or by blows from a hammer, until the internal diameter is equal to twice the thickness of the test piece and the sides become parallel’. Mild steel wire used for hinge pin shall have a tensile strength of 40 kgf/mm2, Min conforming to 1/4 H of IS 280 : 1978 and shall satisfy the wrapping test given below: ‘It shall withstand without breaking or splitting being wrapped 8 times round its own diameter and subsequently straightened’. Cast brass used in the manufacture of brass double-acting spring hinges shall conform to Grade 3 of IS 292 : 1983. Brass sheets used in the manufacture of brass double-acting spring hinges shall conform to alloy designation CuZn 40 of IS 410 : 1977. Brass rods used in the manufacture of brass double-acting spring hinges shall have copper contents not less than 60 percent and tensile strength 40 kgf/mm2, Min ( Grade 2 or 3 ) and shall conform to IS 319 : 1989. Steel wire for springs shall conform to Grade I or Grade 2 of IS 4454 ( Part 1 ) : 1991. ‘Phosphor bronze wire for springs shall conform to Grade 1 of IS 7608 : 1987

This standard lays down the requirements for material, dimensions manufacture, finish and tests of doule-acting spring hinges and corresponding blank hinges used generally for swing doors. Double-acting spring hinges shall be of the following two types according to the material used : a) Mild steel double-acting spring hinges, and b) Brass double-acting spring hinges. Mild steel sheets and plates used in the manufacture of mild steel double-acting spring hinges shall conform to Grade 0 of IS 1079 : 1989 and shall satisfy the following bend test: ‘Suitable test pieces when cold, shall withstand without fracture, being doubled over, either by pressure or by blows from a hammer, until the internal diameter is equal to twice the thickness of the test piece and the sides become parallel’. Mild steel wire used for hinge pin shall have a tensile strength of 40 kgf/mm2, Min conforming to 1/4 H of IS 280 : 1978 and shall satisfy the wrapping test given below: ‘It shall withstand without breaking or splitting being wrapped 8 times round its own diameter and subsequently straightened’. Cast brass used in the manufacture of brass double-acting spring hinges shall conform to Grade 3 of IS 292 : 1983. Brass sheets used in the manufacture of brass double-acting spring hinges shall conform to alloy designation CuZn 40 of IS 410 : 1977. Brass rods used in the manufacture of brass double-acting spring hinges shall have copper contents not less than 60 percent and tensile strength 40 kgf/mm2, Min ( Grade 2 or 3 ) and shall conform to IS 319 : 1989. Steel wire for springs shall conform to Grade I or Grade 2 of IS 4454 ( Part 1 ) : 1991. ‘Phosphor bronze wire for springs shall conform to Grade 1 of IS 7608 : 1987

IS 18297:2023 CABINET HINGES

A cabinet hinge is a type of hardware used to attach doors to the cabinet frame. It allows the door to swing open and close, while also providing support for the weight of the door. These cabinet hinges have advantage over other hinges due to its capability to serve most of the requirement of cabinet and are mostly installed as concealed. These hinges are typically made of metal and can be installed using basic tools. This standard lays down the requirements for materials, type, dimensions, finish and functional performance of cabinet hinges. On the basis of installation of cabinet doors, cabinet hinges can be classified into three types : a) Full overlay b) Half overlay and c) Inset . The size of the cabinet hinge (L) shall be denoted by the length of the hinge in closed condition (mm). Cabinet hinges are manufactured in different sizes (L), the most common sizes of cabinet hinge are 30 mm, 50 mm, 75 mm, 100 mm, 125 mm, 150 mm, 175 mm and –200 mm. Cabinet hinge may be manufactured from any suitable material for example steel and stainless steel. However, the material selected shall not affect the performance of cabinet hinge in accordance with this standard. Manufactures shall declare the grade/type/variety/class of raw material used as per the relevant Indian Standards.

A cabinet hinge is a type of hardware used to attach doors to the cabinet frame. It allows the door to swing open and close, while also providing support for the weight of the door. These cabinet hinges have advantage over other hinges due to its capability to serve most of the requirement of cabinet and are mostly installed as concealed. These hinges are typically made of metal and can be installed using basic tools. This standard lays down the requirements for materials, type, dimensions, finish and functional performance of cabinet hinges. On the basis of installation of cabinet doors, cabinet hinges can be classified into three types : a) Full overlay b) Half overlay and c) Inset . The size of the cabinet hinge (L) shall be denoted by the length of the hinge in closed condition (mm). Cabinet hinges are manufactured in different sizes (L), the most common sizes of cabinet hinge are 30 mm, 50 mm, 75 mm, 100 mm, 125 mm, 150 mm, 175 mm and –200 mm. Cabinet hinge may be manufactured from any suitable material for example steel and stainless steel. However, the material selected shall not affect the performance of cabinet hinge in accordance with this standard. Manufactures shall declare the grade/type/variety/class of raw material used as per the relevant Indian Standards.

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 08 DECEMBER 2023 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for all hinges as listed above to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence. In short, it has become obligatory for all the manufacturers of hinges, whether in India or overseas, to immediately apply for BIS licence and obtain a valid BIS certification licence before that the last date of implementation of the order, i.e., 07 June 2024.

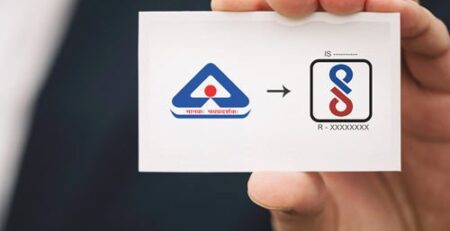

BIS CERTIFICATION SCHEME

The BIS Standards listed above establish a comprehensive framework encompassing various quality parameters that hinges must adhere to. The Bureau of Indian Standards Certification Scheme is a vital framework established by the Indian government to ensure the quality, safety, and reliability of products available in the market. This scheme aims to safeguard consumer interests by setting stringent benchmarks and guidelines that products must meet before they can be deemed compliant. BIS certification covers a wide range of industries and products, encompassing the entire gamut of industrial and manufacturing activity. Various steps involved in the BIS Certification process are enumerated below:

- Standard Identification: Manufacturers identify the relevant BIS standard that applies to their chosen product category. These standards outline the specific quality, safety, and performance requirements that the product must meet.

- Application Submission: Manufacturers submit an application for BIS certification to the Bureau of Indian Standards (BIS), providing details about the product, its specifications, and the desired certification mark.

- Factory Inspection: BIS conducts an inspection of the manufacturer’s production facility to assess the quality control processes, infrastructure, and adherence to relevant standards.

- Sample Testing: BIS collects samples of the product from the manufacturer for testing in authorized BIS laboratories or recognized testing centers. These tests evaluate various parameters specified by the BIS standard.

- Certification Decision: Based on the satisfactory test results and compliance with standards, BIS decides whether to grant certification to the product. If approved, the manufacturer is issued a BIS certification license.

- Regular Monitoring: BIS monitors the manufacturing process of certified products through periodic audits and market surveillance to ensure ongoing compliance with quality control processes and standards.

OMEGA QMS PVT. LTD. – PARTNERING FOR SUCCESS

In the pursuit of achieving BIS certification and maintaining the highest levels of product quality, Omega QMS Pvt. Ltd. emerges as an invaluable partner for manufacturers. Backed by a global presence and a stellar track record of successful collaborations with Fortune 500 companies, Omega QMS provides an extensive array of services designed to streamline the certification process and ensure compliance with industry standards.

- Expert Guidance: Omega brings together a team of seasoned experts who possess in-depth knowledge of regulatory requirements, industry best practices, and intricacies of certification process. These experts guide manufacturers through the complex landscape, offering insights and strategies to navigate the process efficiently.

- Testing and Validation: Omega assists manufacturers in planning and executing necessary tests and validations required for BIS certification.

- Documentation and Compliance: The journey toward BIS certification demands meticulous documentation of processes, materials, and testing procedures. Omega aids manufacturers in creating comprehensive and accurate documentation that aligns with BIS requirements, reducing the risk of errors and rejections.

- Audit Support: Omega prepares manufacturers for BIS audits, which are a crucial part of the certification process. With its expertise, the organization ensures that manufacturers are well-prepared for audits, addressing any issues that may arise and increasing the likelihood of a successful outcome.

- Customized Approach: Each manufacturer’s journey toward BIS certification is unique. Omega understands this and tailors its services to fit the specific needs, challenges, and goals of individual manufacturers, ensuring a personalized and effective approach.

- Global Experience: With presence in over 40 countries, Omega brings global experience to the table. This international exposure allows the organization to offer insights into varying regulatory environments and industry practices, enabling manufacturers to excel globally.

Omega QMS Pvt. Ltd. functions as a strategic partner for manufacturers aiming to achieve BIS Certification. Its multifaceted approach encompasses expert guidance, process control, testing and validation support, documentation assistance, audit preparation, training, and a global perspective. By collaborating with Omega, manufacturers gain a competitive edge in their pursuit of certification while upholding the highest standards of product quality and consumer satisfaction.

For more details you can reach out to Omega at info@globalomega.com

In conclusion, BIS certification is instrumental in validating the quality and performance of various types of hinges, ranging from stainless steel butt hinges to cabinet hinges. By adhering to the prescribed standards and obtaining BIS certification, manufacturers can demonstrate their commitment to delivering safe, reliable, and high-quality products to consumers. With the support of organizations like Omega QMS Pvt Ltd, achieving BIS certification becomes a seamless and rewarding endeavor, fostering trust and confidence in the marketplace.

Comments (2)

Give me procedure for certification

I’m truly enjoying the design and layout of your website. It’s a very easy on the eyes which makes it much more enjoyable for me to come here and visit more often. Did you hire out a developer to create your theme? Exceptional work!