BIS CERTIFICATION FOR POLYPROPYLENE (PP) MATERIALS FOR MOULDING AND EXTRUSION AS PER IS 10951:2020

INTRODUCTION

Polypropylene (PP) has emerged as a widely used thermoplastic material due to its versatility, durability, and cost-effectiveness. With its applications spanning across industries such as packaging, automotive, textiles, and more, ensuring the quality and compliance of PP materials becomes paramount. The Indian Standard IS 10951 sets forth comprehensive specifications for PP materials, encompassing designation systems, properties, testing methods, and certification requirements, thereby ensuring that PP materials meet the stringent criteria laid out by the Bureau of Indian Standards (BIS).

IS 10951:2020 POLYPROPYLENE (PP) MATERIALS FOR MOULDING AND EXTRUSION

IS 10951 provides a comprehensive framework for the classification, properties, testing, and certification of PP materials in accordance with BIS regulations. Key provisions of this standard include:

IS 10951 provides a comprehensive framework for the classification, properties, testing, and certification of PP materials in accordance with BIS regulations. Key provisions of this standard include:

Designation system: PP materials classified based on processing methods, properties, and additives, facilitating clear identification and communication, as outlined by BIS guidelines.

Property requirements: Specifies minimum requirements for essential properties such as Melt Flow Rate (MFR), Flexural Modulus, and Izod Impact Strength, ensuring consistency and reliability in material performance, aligning with BIS standards.

Additional properties: Allows for customization based on specific application requirements, with agreed-upon additional properties and testing methods to be determined between purchasers and suppliers, adhering to BIS certification mandates.

Testing procedures: Defines type tests for product approval and acceptance tests for product identification, ensuring adherence to quality standards and regulatory compliance as mandated by BIS.

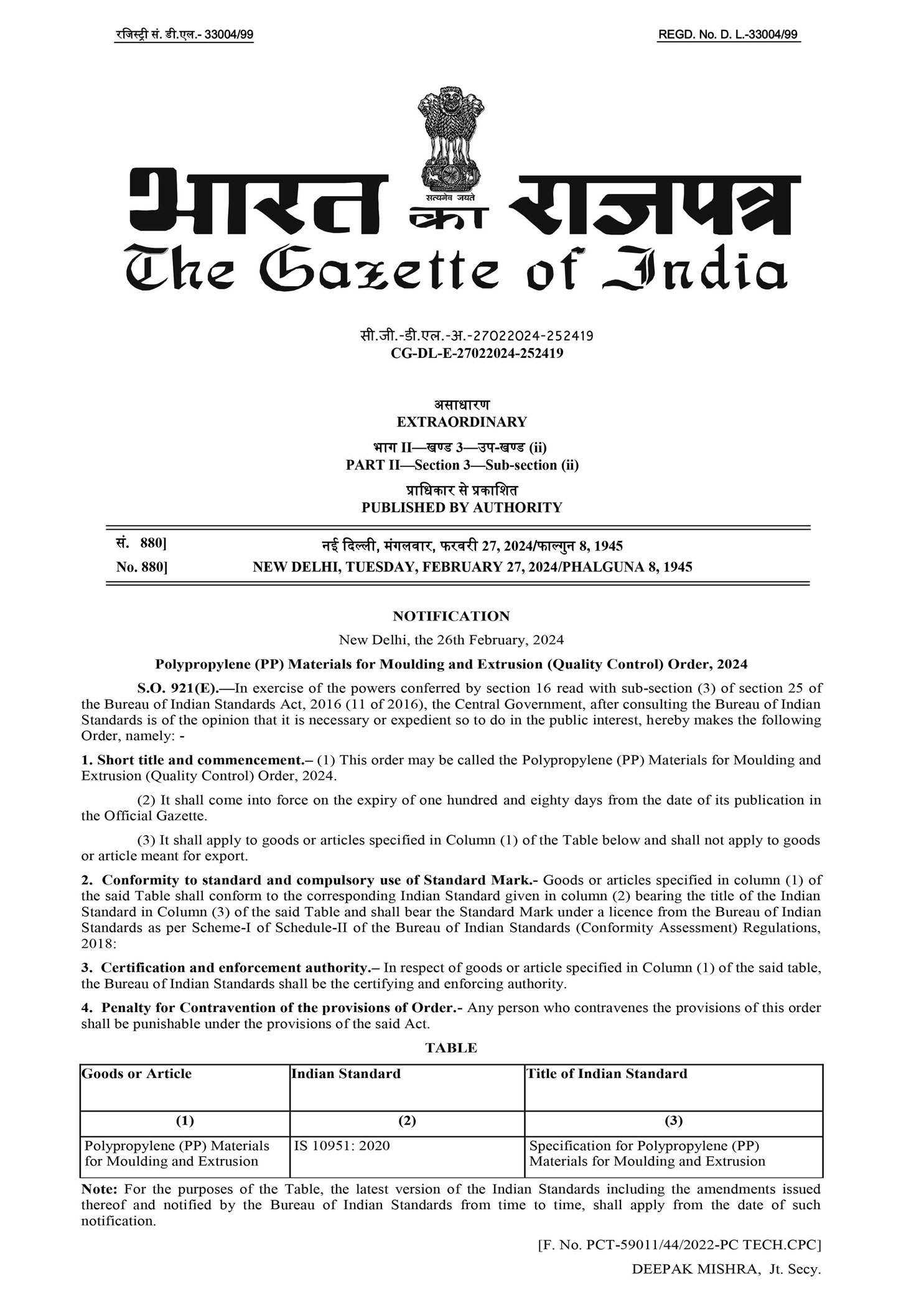

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT OF CHEMICALS AND PETROCHEMICAL, MINISTRY OF CHEMICALS AND FERTILIZERS, GOVT. OF INDIA ON 26 FEBRUARY 2024 FOR MANDATORY BIS CERTIFICATION

In addition to BIS standards, the government of India has issued Quality Control Orders (QCOs) to regulate the production and sale of PP material, thereby ensuring adherence to BIS certification requirements. These QCOs aim to safeguard public health and the environment by imposing restrictions on the use of hazardous substances, ensuring compliance with permissible limits, and mandating labeling requirements to inform consumers about product composition and usage guidelines, all in accordance with BIS guidelines.

The issuance of QCOs underscores the government’s commitment to promoting responsible manufacturing practices and safeguarding public health interests, as outlined by BIS regulations. By enforcing strict regulatory frameworks, QCOs contribute to the overall improvement of product quality, environmental sustainability, and occupational safety within the construction industry, in line with BIS certification directives.

The Department of Chemicals and Petrochemicals, Ministry of Chemicals and Fertilizers, Govt. of India, has issued an order, making it mandatory for all PP material to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark (ISI Mark) of the Bureau of Indian Standards under a valid BIS licence. In short, it has become obligatory for all the manufacturers of PP manufacturers, whether in India or overseas, to immediately apply for BIS licence and obtain a valid BIS certification licence before that the last date of implementation of the order, i.e., 25 August 2024.

BIS CERTIFICATION MARKING: ENSURING COMPLIANCE AND CONSUMER CONFIDENCE

BIS CERTIFICATION MARKING: ENSURING COMPLIANCE AND CONSUMER CONFIDENCE

The Bureau of Indian Standards (BIS) Certification Marking plays a crucial role in ensuring compliance with Indian standards and instilling consumer confidence in products, particularly in the case of PP materials as per IS 10951. Here’s an in-depth look at how BIS Certification Marking ensures compliance and fosters consumer confidence in PP materials:

Quality Assurance: The BIS Certification Marking signifies that the PP materials have undergone rigorous testing and assessment to ensure compliance with the standards set forth in IS 10951, meeting BIS requirements.

Regulatory Compliance: Compliance with BIS standards is mandatory for certain products, including PP materials as per IS 10951, and the BIS Certification Marking serves as proof of adherence to these statutory requirements outlined by regulatory authorities, in line with BIS directives.

Consumer Confidence: The presence of the BIS Certification Marking on PP materials instills confidence in consumers regarding the quality and reliability of the products, assuring them of adherence to established standards and regular quality checks mandated by BIS regulations.

Facilitating Trade: The BIS Certification Marking facilitates trade by establishing a common standard for PP materials across the supply chain, ensuring consistency and reliability in quality, as stipulated by BIS guidelines.

ROLE OF OMEGA QMS PVT LTD. – FACILITATING COMPLIANCE

At Omega QMS Pvt Ltd, we operate at the forefront of regulatory compliance consulting, leveraging over two decades of unparalleled experience to support businesses across more than 40 countries, including compliance with BIS standards for PP materials. Through steadfast partnerships with esteemed Fortune 500 companies, we uphold our commitment to delivering exceptional services that ensure our clients meet rigorous regulatory standards within their industries, including those set by BIS for PP materials.

Our dedicated team works hand in hand with clients, understanding their unique needs and challenges to provide tailored solutions that guarantee compliance with all pertinent regulations, including BIS certification requirements for PP materials. We firmly believe that regulatory compliance transcends mere legal obligation; it is a cornerstone of ethical and responsible business conduct, as mandated by BIS directives.

At Omega QMS Pvt Ltd, our mission extends beyond mere compliance; it’s about fostering a culture of excellence and accountability that drives sustainable success in today’s dynamic business environment, aligned with BIS regulations. Through our unwavering dedication to our clients’ success, we continue to set the benchmark for regulatory compliance consultancy worldwide, including for BIS certification for PP materials.

CONCLUSION

In conclusion, IS 10951 serves as a cornerstone for ensuring the quality, safety, and performance of PP materials in various applications, with BIS certification marking compliance. Compliance with this standard, marked by the BIS Certification, coupled with the expertise of Omega QMS Pvt Ltd., reinforces trust and reliability in the PP supply chain, in accordance with BIS directives. By adhering to the provisions of IS 10951 and leveraging the support of quality experts, manufacturers can enhance their competitiveness, meet regulatory requirements, and ultimately deliver superior quality products to consumers, meeting BIS standards.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply