NAVIGATING QUALITY: THE JOURNEY WITH OMEGA QMS PVT. LTD. IN BIS CERTIFICATION OF STAINLESS STEEL UTENSILS AS PER IS 14756

INTRODUCTION

In the realm of culinary craftsmanship, stainless steel utensils reign supreme, symbolizing durability, hygiene, and functionality. Behind every stainless steel pot, pan, or bowl lies a meticulous process of manufacturing and certification, ensuring adherence to stringent standards. This article embarks on a detailed exploration of Indian Standard IS 14756:2022, governing stainless steel utensils, alongside the BIS certification scheme associated with it. Central to this journey is the pivotal role played by Omega QMS Pvt. Ltd., guiding manufacturers through the certification process with expertise and precision.

UNRAVELLING INDIAN STANDARD IS 14756:2022

Indian Standard IS 14756 serves as the backbone of quality assurance in the stainless steel utensils industry. It meticulously delineates the minimum requirements for various types of utensils, encompassing cooking, serving, table, and storage utensils. From material specifications to detailed guidelines on shapes, dimensions, and finish, the standard leaves no stone unturned in ensuring the quality and durability of stainless steel products. It acts as a compass, guiding manufacturers towards excellence in craftsmanship and reliability in performance.

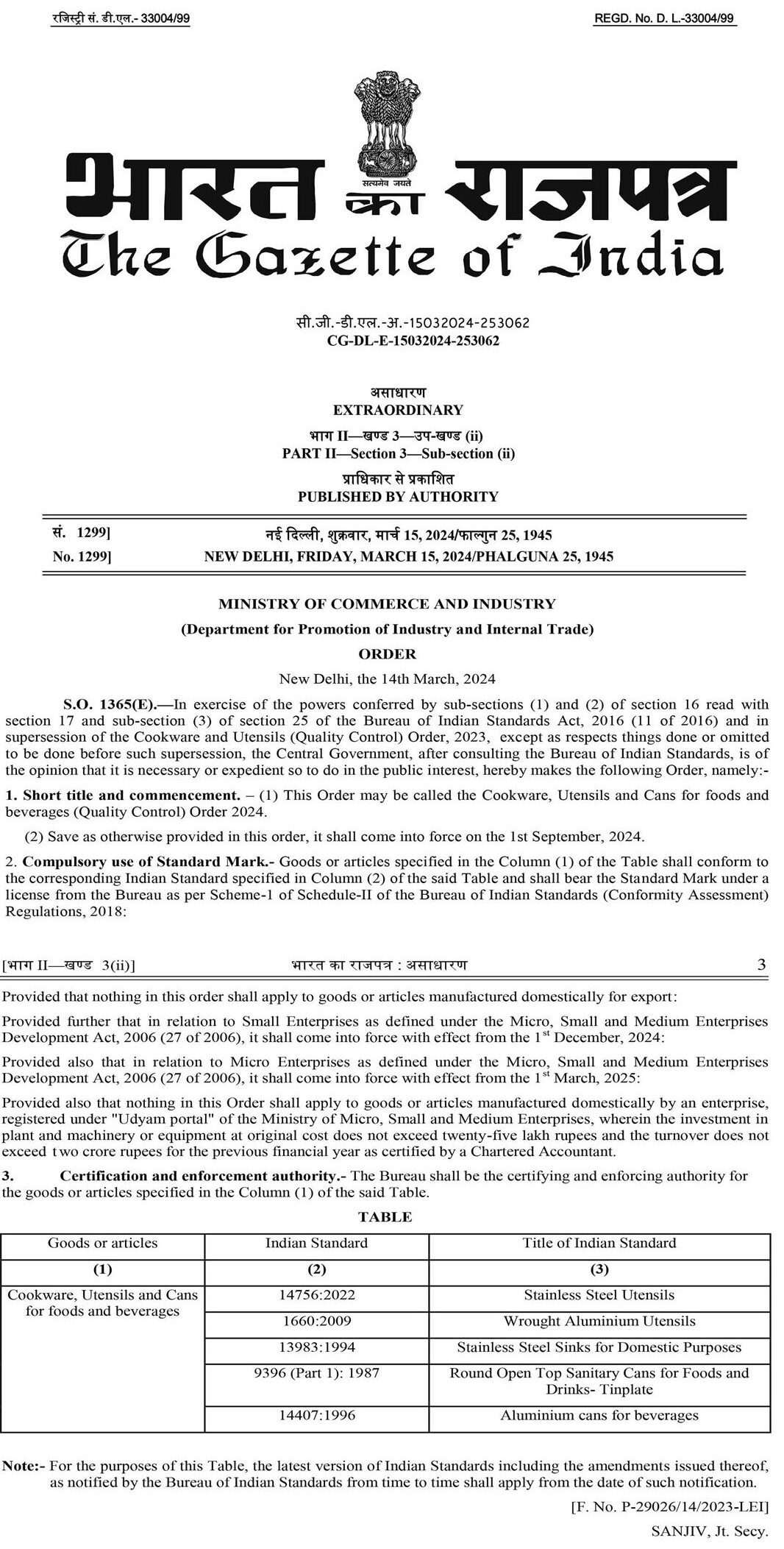

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 14 MARCH 2024 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for all stainless utensils to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence. In short, it has become obligatory for all the manufacturers of stainless steel utensils, wherein in India or overseas, to immediately apply forBIS licence and obtain a valid BIS certification licence before that the last date of implementation of the order, i.e., 01 September 2024.

BIS CERTIFICATION SCHEME FOR STAINLESS STEEL UTENSILS AS PER IS 14756

Under the vigilant eye of the Bureau of Indian Standards (BIS), the certification scheme for stainless steel utensils is a testament to adherence to IS 14756. This certification serves as a seal of approval, assuring consumers of the product’s compliance with rigorous quality and safety standards. The certification process entails a series of rigorous tests, audits, and documentation procedures, aimed at scrutinizing every aspect of production. From material composition to performance under stress tests, each criterion is meticulously evaluated to ensure the utmost quality and reliability.

EMBARKING ON THE JOURNEY WITH OMEGA QMS PVT. LTD.

Omega QMS Pvt Ltd offers comprehensive assistance to companies throughout the BIS certification process for stainless steel utensils. Our team of experienced professionals provides end-to-end support, including:

Registration and Profile Creation: Omega QMS assists manufacturers in this initial step, ensuring that they navigate the online registration process smoothly and accurately set up their profiles.

Pre Certification Factory Audit : Omega carries out pre-certification audit at manufacturer’s site to assess the gaps that exist vis-à-vis the requirements of the standard and assists in plugging the gaps.

Sample Development: Omega comprehensively assist the manufacturer in preparation of the samples in consonance with requirements of the standard and assists in testing the samples in-house to ensure that samples thus prepared meet the expectations of the standard.

Testing : We coordinate with client for the collection of product samples and submit to authorized BIS laboratories or recognized testing centers for testing. We oversee the entire testing process to ensure compliance with BIS standards.

Sample Lot Preparation: Omega extends all out support in preparation of lots of samples to be offered to BIS while inviting them for certification audit. Our assistance ensures that manufacturers present samples efficiently and effectively, facilitating a smoother certification process.

Application Submission: We support manufacturers in preparing and submitting the BIS certification application to the Bureau of Indian Standards (BIS). Our team ensures that the application contains all necessary details about the product, its specifications, and the desired certification mark, thus facilitating a smooth application process.

Factory Inspection: Omega QMS prepares manufacturers for the factory inspection conducted by BIS. We assist in establishing and implementing quality control processes, infrastructure improvements, and ensuring adherence to relevant standards. Our goal is to help manufacturers showcase their commitment to quality during the inspection process.

Sample Testing: We coordinate with client for the collection of product samples from the manufacturer’s facility. Omega QMS ensures that the samples are collected and submitted to authorized BIS laboratories or recognized testing centres for testing. We oversee the entire testing process to ensure compliance with BIS standards.

Grant of Licence: Upon receiving satisfactory test results and ensuring compliance with standards, Omega QMS liaises with BIS to facilitate the certification decision.

Regular Monitoring: Omega QMS continues to support manufacturers post-certification by assisting in regular monitoring activities conducted by BIS. We help manufacturers maintain compliance with quality control processes and standards through periodic audits. Our ongoing support ensures that certified products consistently meet BIS requirements.

Experienced Team: Omega QMS employs an efficient team led by a group of ex-BIS officers, each with over 30 years of experience in the field. Their expertise and insights ensure smooth navigation of the certification process and adherence to BIS standards.

BENEFITS OF CHOOSING OMEGA QMS PVT LTD

Partnering with Omega QMS Pvt Ltd for BIS certification of stainless steel utensils as per IS 14756 offers several advantages:

Expertise: Our team consists of seasoned professionals who possess extensive knowledge of regulatory requirements set forth by BIS. With over 30 years of experience in the field in BIS, our experts are well-equipped to navigate the intricacies of the certification process, ensuring a smooth and efficient experience for our clients.

Time and Cost Savings: We understand the importance of efficiency and cost-effectiveness for our clients. By leveraging our expertise and streamlined processes, we help reduce the time and resources required for certification. This not only saves our clients valuable time but also minimizes associated costs, making the certification process more affordable and accessible.

Assurance of Compliance: Compliance with regulatory standards is non-negotiable, especially in industries like water storage tanks manufacturing where quality and safety are paramount. At Omega QMS, we leave no stone unturned in ensuring that all aspects of the certification process are handled meticulously. This meticulous approach minimizes the risk of rejections or delays, providing our clients with the assurance that their products meet the necessary standards.

Continuous Support: Our commitment to our clients extends beyond the certification process itself. We provide ongoing support to ensure that our clients maintain compliance and adapt to evolving regulatory changes. Whether it’s updates to standards or changes in regulatory requirements, our team is there to provide guidance and assistance every step of the way.

CONCLUSION

In the dynamic landscape of culinary utensils, the journey towards certification is not merely a process but a testament to a commitment to quality and excellence. Indian Standard IS 14756, alongside the BIS certification scheme, serves as pillars of assurance, instilling trust and confidence among consumers and stakeholders. And in this journey, Omega QMS Pvt. Ltd. emerges as a guiding light, steering manufacturers towards the pinnacle of success with unwavering expertise and dedication. Together, they embody the spirit of quality, reliability, and excellence, ensuring that every stainless steel utensil that graces the kitchen bears the mark of distinction and trust

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply