ENSURING QUALITY: BIS CERTIFICATION FOR RING WRENCHES (SPANNERS) AS PER IS 2029 WITH OMEGA QMS PVT. LTD

INTRODUCTION

In the realm of manufacturing and industrial work, precision tools like ring wrenches (Spanners) play a critical role in ensuring that work is carried out with accuracy and efficiency. These tools, widely used in automotive, engineering, and construction industries, must conform to high standards to ensure reliability and durability. The Bureau of Indian Standards (BIS) provides certifications for such tools, ensuring that they meet stringent quality guidelines. The Indian Standard IS 2029:1998 outlines the specifications for ring wrenches, ensuring their conformity with international practices. This article will delve into the details of IS 2029, the BIS certification process for ring wrenches, and how manufacturers can benefit from obtaining this certification.

SUMMARY OF IS 2029:1998

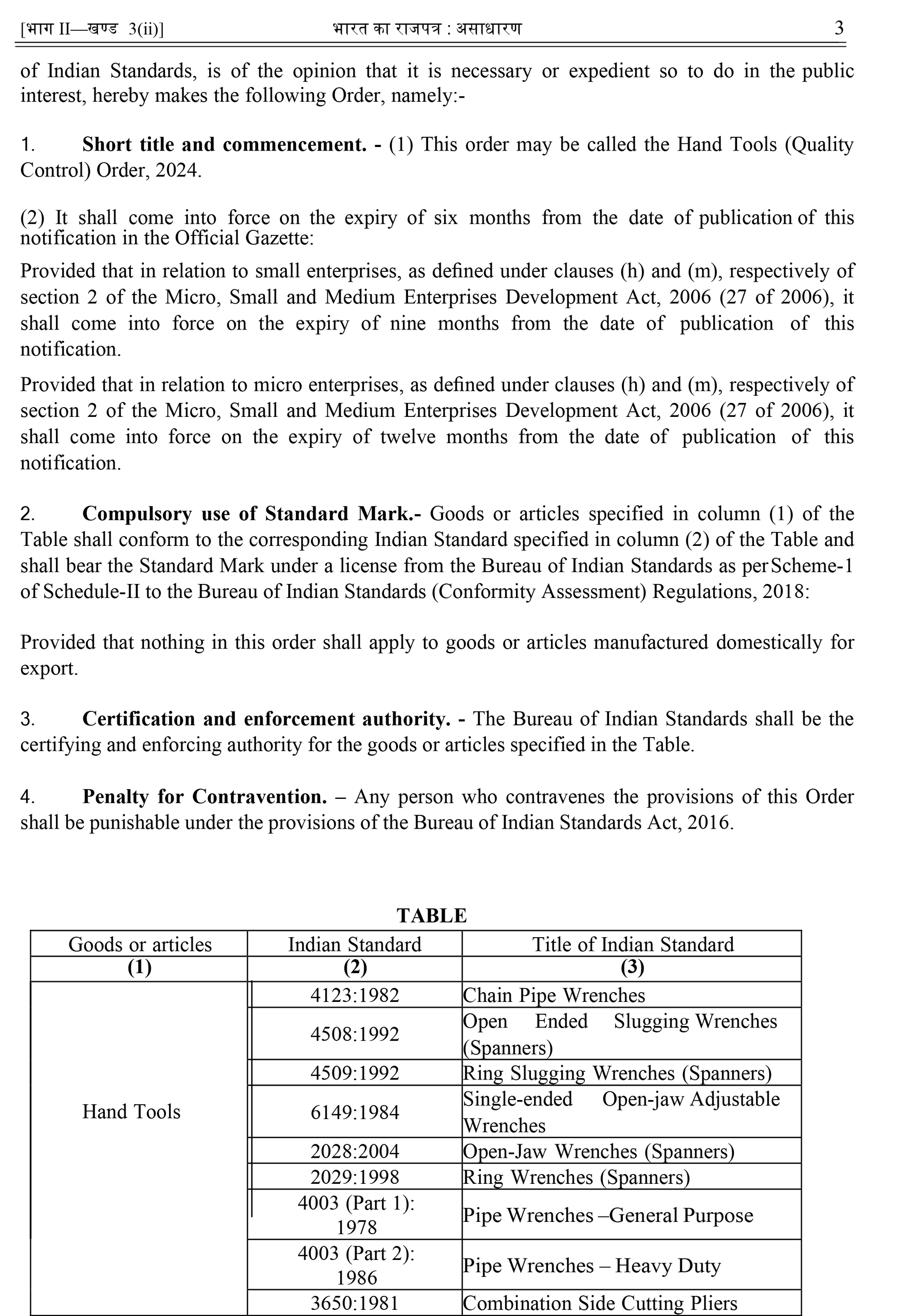

The Indian Standard IS 2029 is a comprehensive guide that specifies the requirements for double-ended, forged ring wrenches of various types—cranked, straight, angled, and offset. This standard ensures that the wrenches adhere to precise dimensions, hardness, and torque testing specifications. The key highlights of IS 2029 include:

Material: Ring wrenches should be made from suitable alloy steel (such as T50Cr4V2), hardened to meet the torque and hardness values as laid out in IS 6131.

Dimensions: The standard provides exact dimensions for various types of ring wrenches, including width across flats, and tolerances for all sizes.

Hardness: The entire length of the wrench must be uniformly hardened, with specific hardness values set for different size combinations. For example, wrenches with widths over 32 mm must have a minimum hardness of 345 HV (35 HRC).

Torque Testing: Wrenches are tested under specific torque values, conforming to Series A (alloy steel) or Series B (carbon steel) of IS 6131. This ensures the durability and strength of the tool under load.

QUALITY CONTROL ORDER (TECHNICAL REGULATION)

The Indian government has made BIS certification for all Ring Wrenches mandatory , whether produced domestically or imported, to ensure it meets the standards set by IS 2029.

BIS CERTIFICATION OF RING WRENCHES (SPANNERS) AS PER IS 2029

BIS offers a certification scheme for ring wrenches, where manufacturers undergo rigorous evaluation to demonstrate compliance with IS 2029. This certification is a mark of quality, enhancing market acceptance and competitiveness.

OMEGA QMS PVT. LTD.: YOUR PARTNER IN BIS CERTIFICATION

Omega QMS Pvt. Ltd. provides comprehensive support throughout the BIS certification process for these Ring Wrenches (Spanner), including:

Application Submission: Assisting in the accurate preparation and submission of the BIS certification application.

Factory Inspection Preparation: Helping manufacturers prepare for BIS inspections by setting up necessary quality control processes.

Sample Testing Coordination: Managing the submission of product samples to BIS- authorized labs for compliance testing.

Grant of Licence: Facilitating the certification process once testing is successfully completed.

For foreign manufacturers, Omega QMS also assists with the following in addition to the above:

Nominating Authorized Indian Representatives: Helping in appointing local representatives for BIS.

Signing Agreements: Guiding manufacturers through the necessary agreements with BIS.

Performance Bank Guarantees: Coordinating the submission of required financial guarantees.

Regular Monitoring: Providing ongoing support to ensure continuous compliance through periodic audits.

BENEFITS OF PARTNERING WITH OMEGA QMS PVT. LTD.

(Leading Provider of Regulatory Compliance & Certification Services since 2001)

Working with Omega QMS offers several key advantages:

Expertise: A team of seasoned professionals with over 30 years of experience in BIS regulations ensures a smooth certification process.

Time and Cost Efficiency: Omega QMS helps reduce the time and cost associated with obtaining BIS certification.

Compliance Assurance: Their thorough approach minimizes the risk of rejections, ensuring products meet all required standards.

Ongoing Support: Continuous assistance to help manufacturers stay compliant with evolving regulatory changes.

CONCLUSION AND FINAL THOUGHTS

In a competitive industrial market, obtaining BIS certification for ring wrenches as per IS 2029 is essential for manufacturers aiming to ensure their product’s quality, durability, and reliability. Omega QMS Pvt. Ltd. plays a pivotal role in guiding manufacturers through the certification process, ensuring compliance and helping them achieve a significant market advantage. Investing in BIS certification is a step toward building trust with consumers and ensuring the long-term success of the product in the marketplace.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply