BIS CERTIFICATION OF COVERED ELECTRODES FOR MANUAL METAL ARC WELDING OF CARBON AND CARBON MANGANESE STEEL

INTRODUCTION

Welding plays a crucial role in various industries, serving as the backbone of construction, manufacturing, automotive, aerospace, and many other sectors. It is a fundamental process for joining metals, enabling the fabrication of structures, machinery, and components essential for modern society. From towering skyscrapers to intricate machinery and pipelines spanning vast distances, welded joints are the invisible bonds that hold our world together. In the realm of welding, adherence to standards is paramount to ensure the safety, reliability, and quality of welded structures and components. One such standard that governs the production and use of welding consumables, particularly covered electrodes for manual metal arc welding, is the Indian Standard IS 814:2004.

IS 814:2004 COVERED ELECTRODES FOR MANUAL METAL ARC WELDING OF CARBON AND CARBON MANGANESE STEEL

IS 814:2004 is an Indian Standard established by the Bureau of Indian Standards (BIS) that outlines the requirements for covered electrodes used in manual metal arc welding processes involving carbon and carbon manganese steel. This standard plays a critical role in regulating the quality and performance of welding consumables, ensuring the integrity and reliability of welded joints across various industries. Key elements involved are as under :Scope: IS 814:2004 defines the scope of covered electrodes for manual metal arc welding, specifying the types of steel covered (carbon and carbon manganese steel) and the intended applications. Tensile Strength: The standard sets maximum limits for the tensile strength of the weld metal deposited by the electrodes, ensuring that it does not exceed 610 MPa.

Hydrogen Control: Certain electrodes are designed to control hydrogen levels in the weld metal, mitigating the risk of hydrogen-induced cracking.

Classification System: Electrodes are classified based on their properties and characteristics using a coding system, facilitating the selection of suitable electrodes for specific welding applications.

Type of Covering: Various types of electrode coverings, such as acid, basic, rutile, and semi-basic, are defined, each offering unique performance attributes.

Welding Positions: Electrodes are specified for use in various welding positions, including flat, vertical, horizontal, and overhead positions, ensuring versatility and adaptability in welding operations.

Current Conditions: Electrodes are designed to operate under specific welding current and voltage conditions, optimizing performance and efficiency during welding processes.

IS 6419 WELDING RODS AND BARE ELECTRODES FOR GAS SHIELDED ARC WELDING OF STRUCTURAL STEEL

IS 6419 WELDING RODS AND BARE ELECTRODES FOR GAS SHIELDED ARC WELDING OF STRUCTURAL STEEL

This standard prescribes of solid filler rods and wires for welding structural steel by inert gas tungsten arc welding (TIG), gas metal arc welding (MIG) or CO2 welding process. The chemical composition and tensile properties of filler rods and wires are also specified. This standard also prescribes mechanical properties of melt deposits. Rods supplied in straight lengths shall preferably have lengths 250, 350, 450, 500, 600, 750, 900 , 1000 mm. The temper of the filler metals shall be such that they are suitable for uninterrupted feeding on automatic or semi-automatic welding equipment. The cast of filler metals shall be such as to have imparted a curvature to the filler metal so that a specimen sufficient in length to found one loop or a maximum 3 m when cut from the package. Soundness test, all weld metal mechanical test, all weld impact test are some of the tests specified for wires and rods.

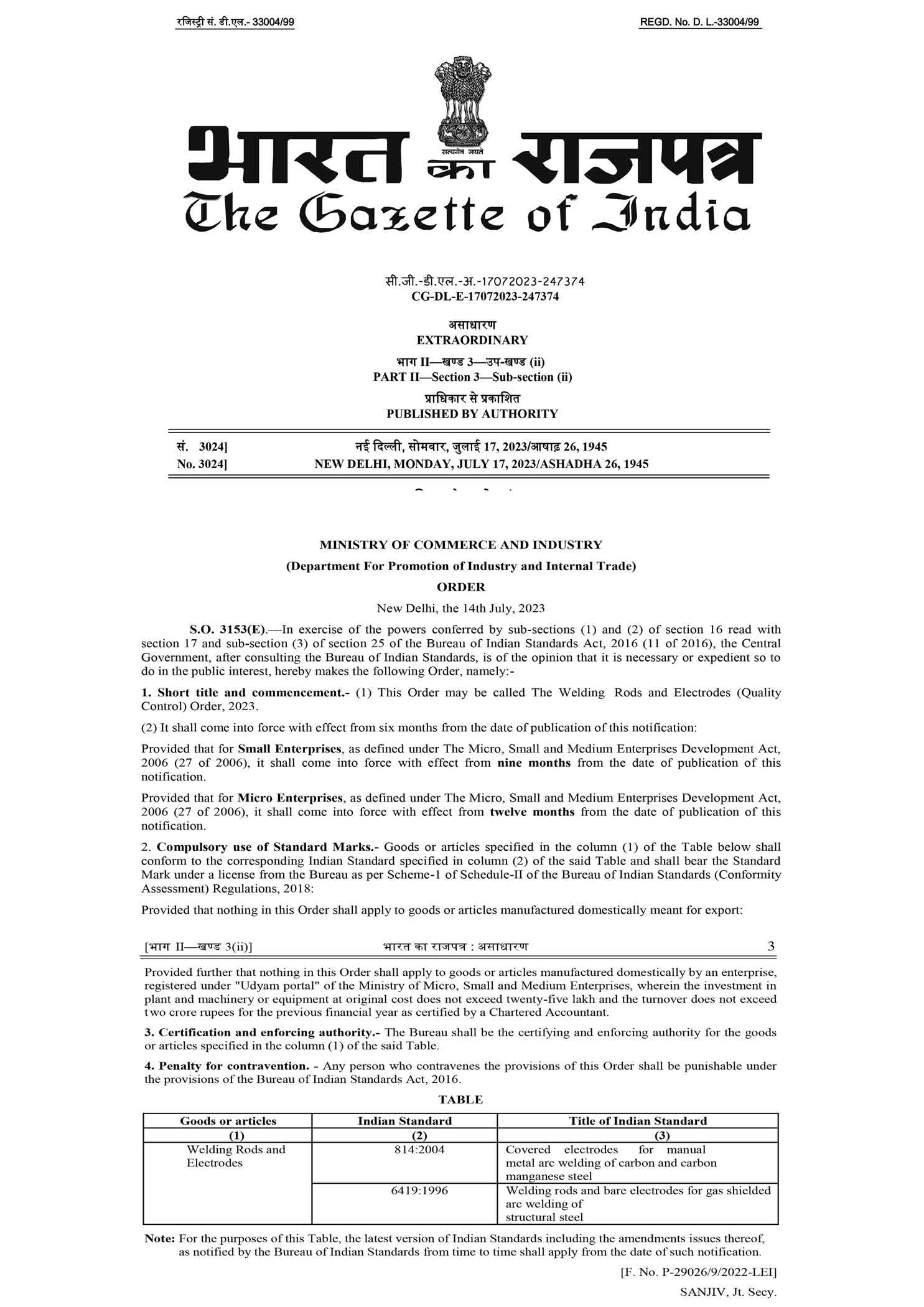

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 09 AUGUST 2023 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for electrodes to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark (ISI Mark) of the Bureau of Indian Standards under a valid BIS license. In short, it has become obligatory for all the manufacturers of aluminium cans, whether in India or overseas, to immediately apply for BIS license and obtain a valid BIS certification license for electrodes.

BIS CERTIFICATION SCHEME AT A GLANCE

The BIS Certification Scheme, a crucial framework by the Indian government, ensures the quality, safety, and reliability of products, including aluminium cans for beverages. The scheme covers various industries and products, involving standard identification, application submission, factory inspection, sample testing, certification decision, and regular monitoring, establishing compliance with IS 814.

OMEGA QMS PVT. LTD. (FACILITATING COMPLIANCE)

In the pursuit of achieving BIS certification and maintaining the highest levels of product quality, Omega QMS Pvt. Ltd. emerges as an invaluable partner for manufacturers. Backed by a global presence and a stellar track record of successful collaborations with Fortune 500 companies, Omega QMS provides an extensive array of services designed to streamline the certification process and ensure compliance with industry standards.

Expert Guidance: Omega brings together a team of seasoned experts who possess in-depth knowledge of regulatory requirements, industry best practices, and intricacies of the certification process. These experts guide manufacturers through the complex landscape, offering insights and strategies to navigate the process efficiently.

Testing and Validation: Omega assists manufacturers in planning and executing necessary tests and validations required for BIS certification.

Documentation and Compliance: The journey toward BIS certification demands meticulous documentation of processes, materials, and testing procedures. Omega aids manufacturers in creating comprehensive and accurate documentation that aligns with BIS requirements, reducing the risk of errors and rejections.

Inspection / Audit Support: Omega prepares manufacturers for BIS audits, which are a crucial part of the certification process. With its expertise, the organization ensures that manufacturers are well-prepared for audits, addressing any issues that may arise and increasing the likelihood of a successful outcome.

Customized Approach: Each manufacturer’s journey toward BIS certification is unique. Omega understands this and tailors its services to fit the specific needs, challenges, and goals of individual manufacturers, ensuring a personalized and effective approach.

Global Experience: With a presence in over 40 countries, Omega brings global experience to the table. This international exposure allows the organization to offer insights into varying regulatory environments and industry practices, enabling manufacturers to excel globally.

Omega QMS Pvt. Ltd. functions as a strategic partner for manufacturers aiming to achieve BIS Certification. Its multifaceted approach encompasses expert guidance, process control, testing and validation support, documentation assistance, audit preparation, training, and a global perspective. By collaborating with Omega, manufacturers gain a competitive edge in their pursuit of certification while upholding the highest standards of product quality and consumer satisfaction.

For more details, you can reach out to Omega at info@globalomega.com.

CONCLUSION

In conclusion, IS 814:2004 serves as a cornerstone in the realm of manual metal arc welding, providing essential guidelines and specifications for covered electrodes. By adhering to this standard, stakeholders can uphold the highest standards of quality, safety, and performance in welding operations, ensuring the longevity and reliability of welded structures and components.

In conclusion, IS 814:2004 stands as a beacon of quality and reliability in the world of manual metal arc welding. Through its comprehensive specifications and rigorous standards, this Indian Standard ensures that covered electrodes used in welding processes meet the highest levels of performance, safety, and integrity. By adhering to IS 814:2004, manufacturers can produce welding consumables that inspire confidence and trust among welders, inspectors, and end-users. Welders can rely on these electrodes to deliver consistent and dependable results, whether they’re working on structural projects, fabrication, repairs, or maintenance tasks.

Moreover, the BIS certification marking associated with IS 814:2004 provides an added layer of assurance, indicating that welding consumables have undergone stringent testing and comply with established quality benchmarks. Furthermore, the role of Omega QMS Pvt. Ltd. cannot be overstated in ensuring compliance with IS 814:2004 and other relevant standards. Omega QMS empowers manufacturers to implement robust quality control measures, track production processes, and continuously improve product quality and consistency.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Comments (2)

I can’t believe how amazing this article is! The author has done a phenomenal job of delivering the information in an compelling and educational manner. I can’t thank him enough for providing such priceless insights that have definitely enriched my understanding in this subject area. Hats off to her for producing such a masterpiece!

Wow, wonderful blog layout! How long have you been blogging for? you make blogging look easy. The overall look of your site is fantastic, as well as the content!