BIS CERTIFICATION FOR STEEL WIRE ROPES FOR GENERAL ENGINEERING PURPOSE AS PER IS 2266:2019

INTRODUCTION

Steel wire ropes play a pivotal role in diverse engineering applications, such as cranes and excavators, where safety and reliability are paramount. Adherence to quality standards, particularly the Indian Standard IS 2266:2019, is crucial. This article explores the essential facets of IS 2266, quality control orders, the BIS certification marking scheme, and the role of Omega QMS Pvt. Ltd. in ensuring compliance with BIS Certification of Steel Wire Ropes as per IS 2266:2019

ABSTRACT FROM IS 2266:2019 STEEL WIRE ROPES FOR GENERAL ENGINEERING PURPOSE

Scope: IS 2266 outlines general requirements for steel wire ropes used in cranes, excavators, and other engineering applications. The article emphasizes the necessity of obtaining BIS Certification of Steel Wire Ropes as per IS 2266 for compliance.

Minimum Breaking Force: The standard specifies minimum breaking forces for various types of steel wire ropes, as detailed in Table 1 to 13 of IS 2266, reinforcing the importance of BIS Certification.

Construction: Rope construction is specified in the standard, allowing variations based on engineering applications with user consent, all of which must align with BIS Certification of Steel Wire Ropes.

Core: IS 2266 provides specifications for both fibre core and steel core, essential considerations for obtaining BIS Certification.

Joints: Tucked joints are permitted for wires of 0.5 mm diameter and smaller during rope making, highlighting the need for precision in manufacturing for BIS Certification.

Galvanizing: Galvanizing requirements conform to Type (A, AB, or B) of IS 1835, reinforcing the importance of adhering to BIS Certification standards.

QUALITY ASSURANCE FRAMEWORKS: GOVERNMENTAL APPROACH

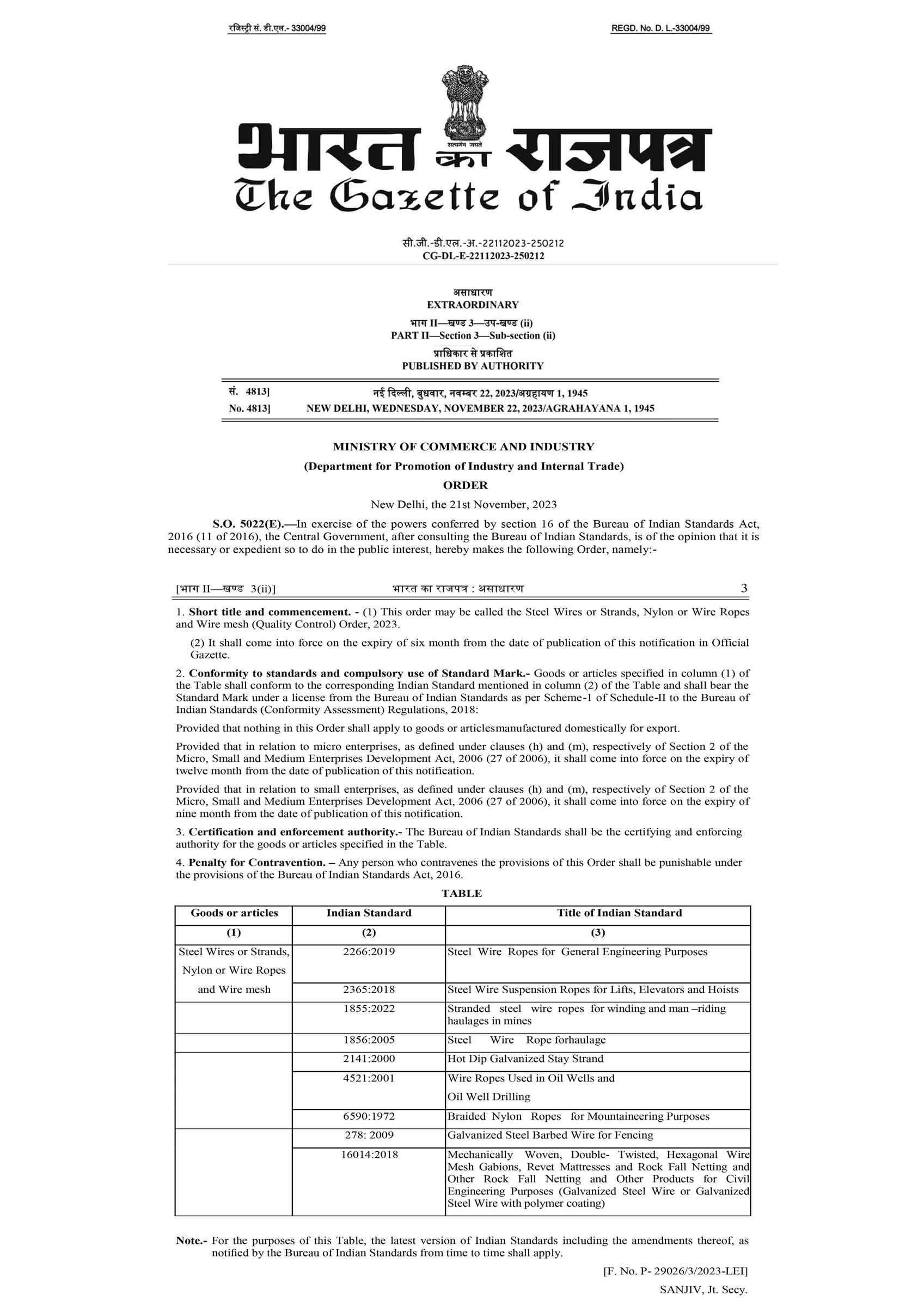

The Government of India periodically updates Quality Control Orders (QCO), recently including Steel Wire Ropes for General Engineering Purposes as per IS 2266:2019. The pivotal requirement is obtaining BIS Certification of Steel Wire Ropes as per IS 2266 for products imported into India.

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY DPIIT

The DPIIT, Ministry of Commerce & Industry, Govt. of India, issued an order on November 21, 2023, mandating BIS Certification for steel wire ropes used in India. The ISI Mark under a valid BIS license becomes obligatory from May 20, 2024, for both Indian and overseas manufacturers, emphasizing the significance of BIS Certification.

BIS CERTIFICATION SCHEME AT A GLANCE:

The BIS Certification Scheme, a pivotal framework by the Indian government, ensures product quality, safety, and reliability. The certification process involves standard identification, application submission, factory inspection, sample testing, certification decision, and regular monitoring, all essential steps for BIS Certification of Steel Wire Ropes.

OMEGA QMS PVT. LTD. – PARTNERING FOR SUCCESS

In the pursuit of BIS Certification of Steel Wire Ropes as per IS 2266, Omega QMS Pvt. Ltd. emerges as an invaluable partner. With global presence and a track record of collaborations with Fortune 500 companies, Omega QMS offers services for streamlining the certification process, ensuring compliance with industry standards and BIS Certification requirements.

Expert Guidance: Omega provides expert guidance, leveraging in-depth knowledge of regulatory requirements, industry best practices, and the intricacies of the certification process, a crucial aspect for BIS Certification of Steel Wire Ropes as per IS 2266.

Testing and Validation: Omega supports manufacturers in planning and executing necessary tests and validations required for BIS Certification of Steel Wire Ropes as per IS 2266, ensuring the ropes meet IS 2266 standards.

Documentation and Compliance: Meticulous documentation aligning with BIS requirements is crucial for BIS Certification of Steel Wire Ropes as per IS 2266, and Omega assists manufacturers in creating comprehensive and accurate records.

Audit Support: BIS audits are pivotal for certification, and Omega prepares manufacturers by addressing potential issues, increasing the likelihood of a successful outcome for BIS Certification.

Customized Approach: Recognizing the uniqueness of each manufacturer’s journey, Omega tailors its services to specific needs, challenges, and goals, ensuring a personalized and effective approach for BIS Certification.

Global Experience: With a presence in over 40 countries, Omega brings a global perspective, offering insights into varying regulatory environments and industry practices for manufacturers aiming for BIS Certification.

CONCLUSION

Adhering to Indian Standard IS 2266 is indispensable for ensuring the safety and reliability of steel wire ropes in engineering applications. Compliance with the standard, rigorous quality control, and obtaining BIS Certification of Steel Wire Ropes as per IS 2266 are imperative. With the support of organizations like Omega QMS Pvt. Ltd., manufacturers can navigate regulatory requirements, enhance product quality, and meet customer expectations effectively. Prioritizing compliance and quality assurance contributes to safer and more reliable engineering practices and ensures successful BIS Certification.

For your certification needs pls contact info@globalomega.com 011-41413939 (100 LINES)

For your certification needs pls contact info@globalomega.com 011-41413939 (100 LINES)

908-909, Hemkunt House, Rajendra Place,New Delhi – 110008, India

Leave a Reply