BIS CERTIFICATION FOR GENERAL PURPOSE PIPE WRENCHES AS PER IS 4003 (PART 1): A COMPREHENSIVE GUIDE TO CERTIFICATION BY OMEGA QMS PVT. LTD

INTRODUCTION

Pipe wrenches are indispensable tools in plumbing, mechanical, and construction industries. They are designed to grip and turn pipes or round fittings, playing a crucial role in a wide variety of applications. To ensure the safety, durability, and efficiency of pipe wrenches, they must meet strict manufacturing standards. The Bureau of Indian Standards (BIS) certification is essential for guaranteeing that pipe wrenches conform to such standards, specifically outlined in IS 4003 (Part 1). This article explores the key aspects of IS 4003 (Part 1) for general-purpose pipe wrenches, the BIS certification process, and the assistance provided by Omega QMS Pvt. Ltd. to manufacturers in obtaining this certification.

SUMMARY OF IS 4003 (PART 1) – GENERAL PURPOSE PIPE WRENCHES

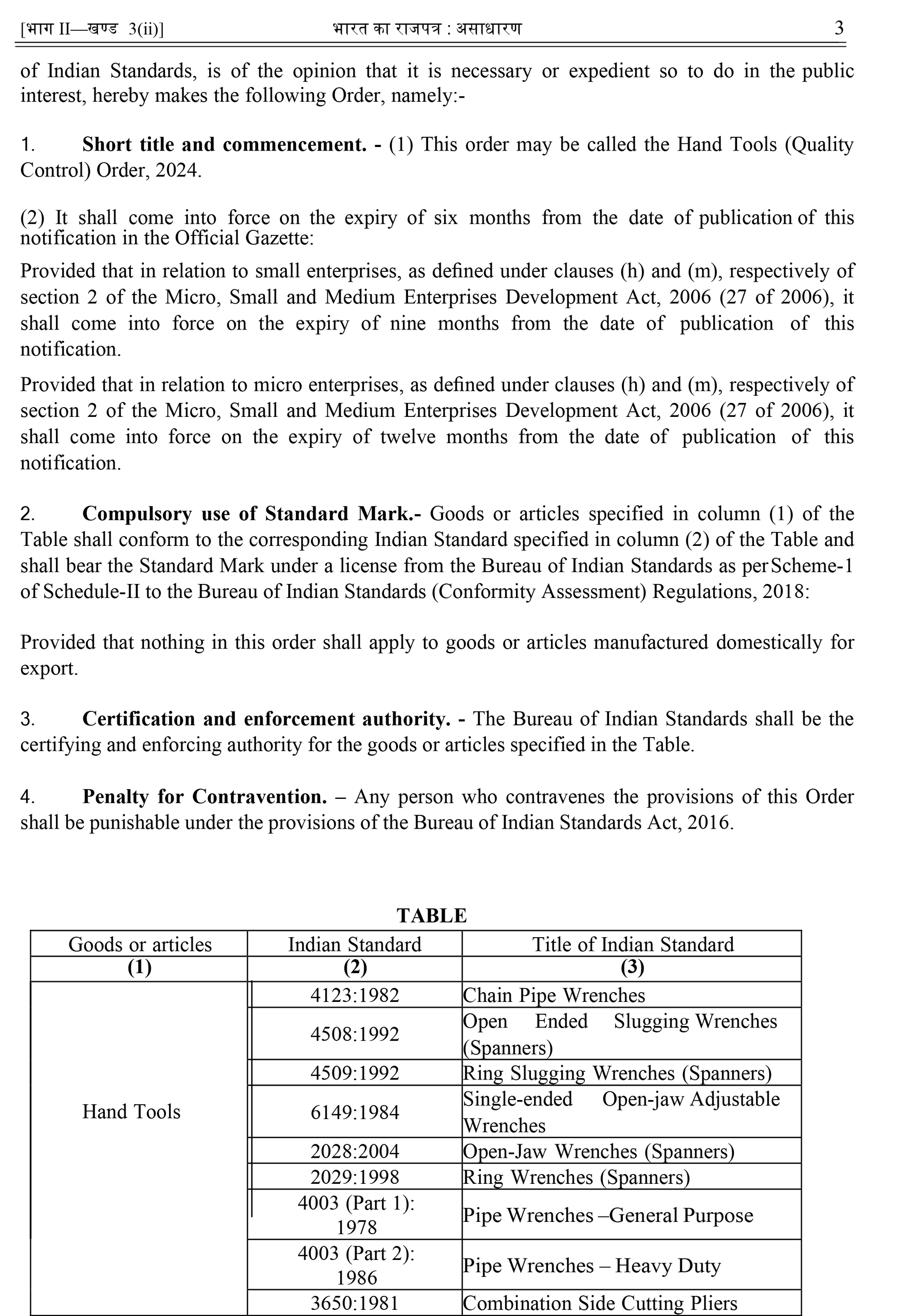

The Indian Standard IS 4003 (Part 1) specifies the requirements for general-purpose pipe wrenches, covering aspects such as material composition, hardness, dimensions, and operational performance. This standard aims to ensure that pipe wrenches maintain high levels of safety and reliability during use. Key highlights of the standard include:

Material: The components of pipe wrenches, including the handle, jaws, frame, and adjusting nut, must be made from suitable materials such as carbon steel or malleable cast iron, as per the specifications in IS 1570. For example, handles and movable jaws may use carbon steels like 40C8, 50C4, or 65C6, while springs are made of alloy steel like 50Cr4 (IS 4003 Part 1).

Hardness and Strength: The hardness requirements for pipe wrenches are essential to ensure durability and prevent wear. Jaws must have a hardness between 510 to 700 HV (50 to 60 HRC), ensuring that they grip pipes effectively without deformation. The handle and other components must also meet specific hardness levels (IS 4003 Part 1).

Dimensions and Capacity: IS 4003 (Part 1) specifies the nominal sizes of pipe wrenches, ranging from 200 mm to 1200 mm in length, with varying capacities for gripping pipes of different diameters. For example, a 200 mm wrench has a maximum pipe gripping capacity of 20 mm, while a 1200 mm wrench can handle pipes up to 130 mm in diameter (IS 4003 Part 1).

Performance Tests: The standard includes rigorous performance tests, such as the static load test and the static-shock load test. These tests ensure that the wrench can withstand high torques and forces without permanent deformation or cracking, proving its reliability during heavy-duty tasks(IS 4003 Part 1).

QUALITY CONTROL ORDER AND TECHNICAL REGULATION

The Indian government has mandated BIS certification for all General Purpose Pipe Wrenches, whether domestically produced or imported, to ensure compliance with IS 4003 (Part 1). This regulation aims to uphold safety and quality standards across the board, making certification essential for manufacturers to market their tools in India.

OMEGA QMS PVT. LTD.: YOUR PARTNER IN BIS CERTIFICATION

Omega QMS Pvt. Ltd. specializes in guiding manufacturers through the often complex BIS certification process. Their comprehensive support includes:

Application Submission: Assisting manufacturers in the precise preparation and submission of BIS certification applications.

- Factory Inspection Preparation: Helping set up essential quality control processes to ensure a smooth BIS inspection.

- Sample Testing Coordination: Managing the submission of product samples to BIS-authorized labs for compliance testing.

- Grant of Licence: Facilitating certification upon successful completion of testing.

For foreign manufacturers, Omega QMS also provides assistance with:

- Nominating Authorized Indian Representatives: Aiding in the appointment of local representatives for BIS.

- Signing Agreements: Guiding manufacturers through necessary agreements with BIS.

- Performance Bank Guarantees: Coordinating the submission of required financial guarantees.

- Ongoing Monitoring: Offering continuous support to maintain compliance through regular audits.

Why Partner with Omega QMS Pvt. Ltd.?

Working with Omega QMS provides several significant advantages:

- Expertise: With over 30 years of experience in BIS regulations, their team of experts ensures a smooth and efficient certification process.

- Time and Cost Efficiency: Omega QMS helps reduce both the time and cost involved in securing BIS certification.

- Compliance Assurance: Their meticulous approach minimizes the risk of rejection, ensuring that products meet all necessary standards.

- Ongoing Support: Omega QMS provides continuous assistance to keep manufacturers up to date with evolving regulatory changes.

CONCLUSION AND FINAL THOUGHTS

For manufacturers of general-purpose pipe wrenches, obtaining BIS certification as per IS 4003 (Part 1) is crucial for ensuring product quality and safety. This certification enhances the product’s credibility in the market, providing assurance to consumers about its reliability and durability. Omega QMS Pvt. Ltd. plays a pivotal role in facilitating this process, offering expert guidance from application to certification. By ensuring compliance with BIS standards, manufacturers can gain a competitive edge in the industry, contributing to safer and more efficient working environments.

Investing in BIS certification is a long-term commitment to quality, and with Omega QMS’s assistance, manufacturers can achieve this milestone with ease and efficiency.

For your Certification needs pls contact:

OMEGA QMS PVT. LTD.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Email: info@globalomega.com, Phone: 011-41413939(100 lines)

Leave a Reply