BIS CERTIFICATION FOR AUTOMOTIVE NON-WOVEN CARPETS AS PER IS 17758 WITH OMEGA QMS PVT. LTD.

INTRODUCTION

Automotive non-woven carpets and mats are essential for protecting the interior surfaces of vehicles from dirt, moisture, and wear, while also enhancing comfort and aesthetics. These non-woven materials are specifically designed for durability, ease of maintenance, and resistance to environmental factors, which is why their quality is regulated by the Bureau of Indian Standards (BIS) under IS 17758: 2022. This standard sets forth stringent guidelines for these products, covering essential aspects such as structural integrity, performance under stress, and environmental safety.

Obtaining BIS certification is crucial for manufacturers to ensure their automotive non-woven carpets meet these high standards, and Omega QMS Pvt. Ltd. provides invaluable assistance in navigating this certification process. In this article, we’ll explore the IS 17758 standard requirements and how Omega QMS facilitates certification, ensuring manufacturers meet regulatory requirements and bring top-quality products to market.

SUMMARY OF IS 17758: SPECIFICATIONS FOR AUTOMOTIVE NON-WOVEN CARPETS AND MATS

The IS 17758 standard provides comprehensive guidelines for manufacturing non-woven carpets and mats for automotive use, focusing on material durability, safety, and resistance to environmental stresses.

Scope and Classification:

This standard applies to non-woven carpets and mats used in various areas of a vehicle, such as floors, deck surfaces, seat backs, trunk sides, and trim surfaces. The products are classified into three types based on their intended application:

Type I: For vehicle flooring.

Type II: For trim surfaces.

Type III: For deck surfaces, seat backs, and luggage compartments.

Construction and Design:

Non-Woven Fabric: The carpets are constructed using needle-punched non-woven fabric, which ensures compactness and durability. This process involves compressing and interlocking fibre webs with barbed needles to form a robust, cohesive structure.

Backings and Adhesives: Appropriate backing is applied to support the carpet’s installation and stability, preventing issues such as curling or sliding. Specific adhesives may be used to increase stability and prevent detachment under stress.

Dimensional and Physical Specifications:

Dimensions: Carpet rolls must meet agreed-upon length and width measurements within a tolerance of ±1%.

Mass and Thickness: Manufacturers must adhere to their declared values for carpet mass and thickness with a tolerance of ±10%, ensuring product consistency.

Strength and Durability:

Tensile Strength: Type I and Type II carpets require a minimum tensile strength of 250 N/cm, while Type III carpets require 400 N/cm, to withstand wear and deformation.

Tear Strength: A minimum tear strength of 50 N is mandatory to ensure durability under regular vehicle use.

Wear Resistance: Carpets must achieve a minimum wear resistance grade of 3 under specified testing conditions, confirming their resilience to abrasion and rough handling.

Safety and Environmental Compliance:

Flame Resistance: All carpet types must meet strict flame resistance standards to reduce fire hazards. This includes conditions such as self-extinguishing capabilities and a maximum burn rate.

Odour and Fogging Tests: To ensure indoor air quality and passenger comfort, carpets undergo both dry and wet odour tests as well as fogging tests, which measure volatile organic compound (VOC) emissions that can cause windshield fogging.

Dimensional Stability: Carpets must show minimal changes under varied water and heat conditions, with a maximum of 2% allowable dimensional change.

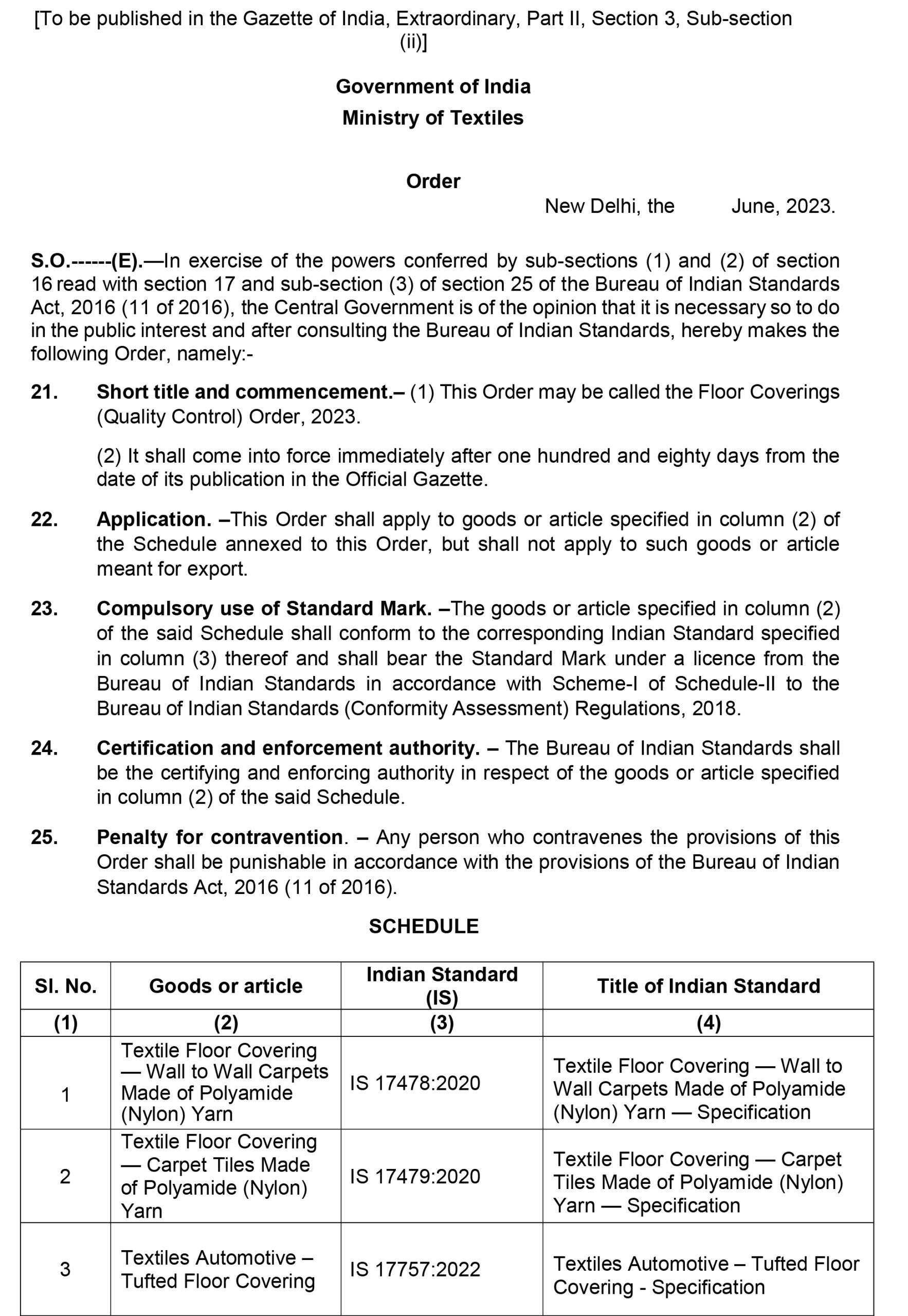

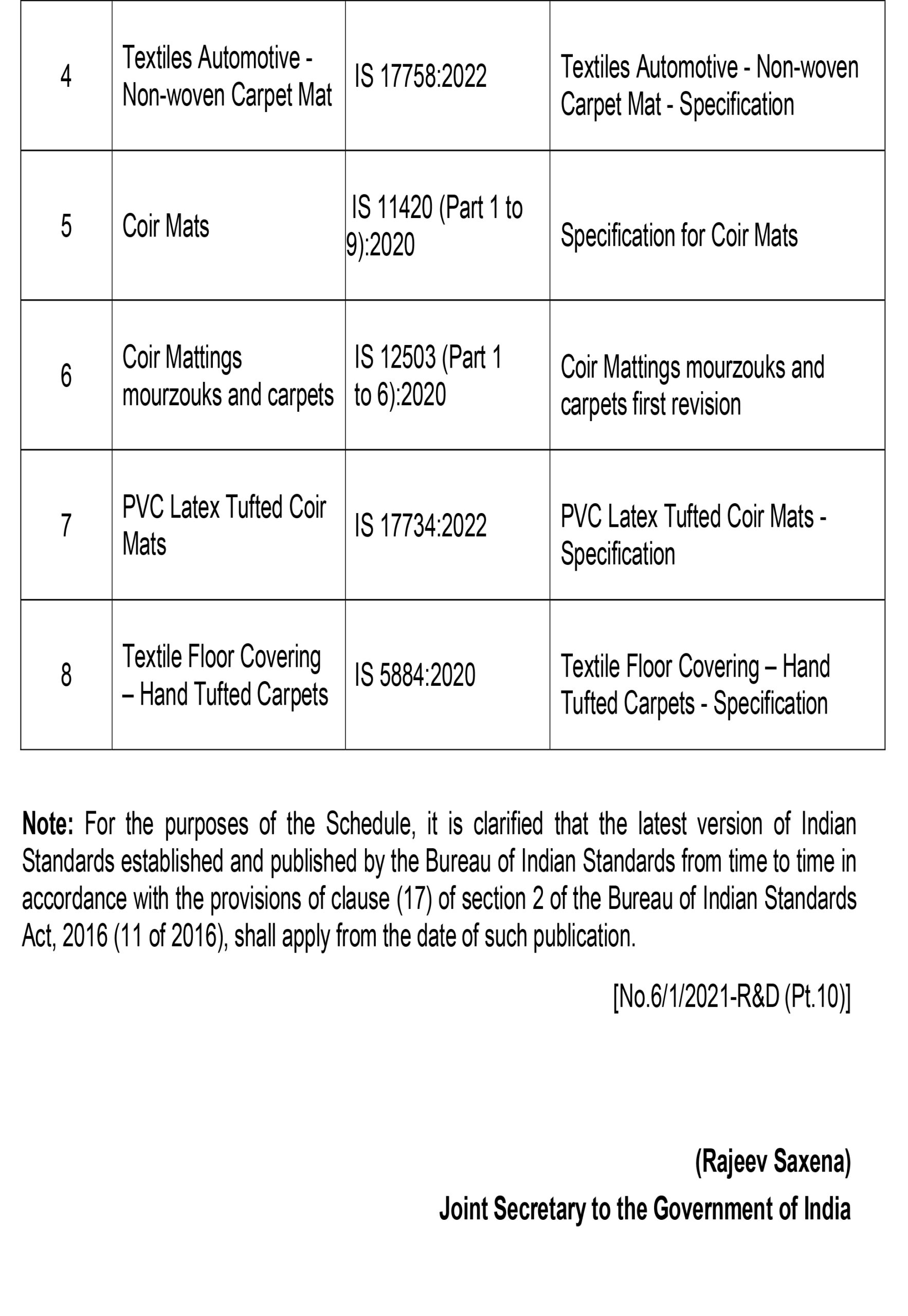

DRAFT QUALITY CONTROL ORDER AND TECHNICAL REGULATION

The Indian government proposes to make BIS certification for non-woven automotive carpets, whether domestically produced or imported, mandatory as per IS 17758 to ensure compliance. This regulation aims to uphold safety and quality standards across the board, making certification essential for manufacturers to market their product in India.

BIS CERTIFICATION FOR NON-WOVEN AUTOMOTIVE CARPETS AS PER IS 17758

BIS offers a comprehensive certification scheme for non-woven automotive carpets, requiring manufacturers to undergo rigorous evaluation to demonstrate their compliance with IS 17758. Achieving this certification not only guarantees a high-quality product but also boosts market credibility, enhancing the manufacturer’s competitiveness.

OMEGA QMS PVT. LTD.: YOUR PARTNER IN BIS CERTIFICATION

Omega QMS Pvt. Ltd. specializes in guiding manufacturers through the often complex BIS certification process. Their comprehensive support includes:

- Application Submission: Assisting manufacturers in the precise preparation and submission of BIS certification applications.

- Factory Inspection Preparation: Helping set up essential quality control processes to ensure a smooth BIS inspection.

- Sample Testing Coordination: Managing the submission of product samples to BIS-authorized labs for compliance testing.

- Grant of Licence: Facilitating certification upon successful completion of testing.

For foreign manufacturers, Omega QMS also provides assistance with:

- Nominating Authorized Indian Representatives: Aiding in the appointment of local representatives for BIS.

- Signing Agreements: Guiding manufacturers through necessary agreements with BIS.

- Performance Bank Guarantees: Coordinating the submission of required financial guarantees.

- Ongoing Monitoring: Offering continuous support to maintain compliance through regular audits.

WHY PARTNER WITH OMEGA QMS PVT. LTD.?

Working with Omega QMS provides several significant advantages:

- Expertise: With over 30 years of experience in BIS regulations, their team of experts ensures a smooth and efficient certification process.

- Time and Cost Efficiency: Omega QMS helps reduce both the time and cost involved in securing BIS certification.

- Compliance Assurance: Their meticulous approach minimizes the risk of rejection, ensuring that products meet all necessary standards.

- Ongoing Support: Omega QMS provides continuous assistance to keep manufacturers up to date with evolving regulatory changes.

CONCLUSION AND FINAL THOUGHTS

IS 17758 certification is essential for manufacturers of automotive non-woven carpets, ensuring that products meet high standards for durability, safety, and environmental impact. Certification assures consumers that the carpets will not only protect vehicle interiors but also contribute to a healthier, more comfortable in-car environment.

By partnering with Omega QMS Pvt. Ltd., manufacturers can streamline the BIS certification process, benefiting from expert guidance and comprehensive support at every stage. Omega QMS’s role in documentation, testing, inspection preparation, and compliance maintenance helps manufacturers bring BIS-certified products to market more efficiently. With Omega QMS’s assistance, manufacturers can confidently produce high-quality automotive carpets that meet Indian standards, providing both safety and comfort for vehicle occupants.

OMEGA QMS PVT. LTD.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Phone: 011-41413939(100 lines), Email: info@globalomega.com,

sales@globalomega.com, mktg@globalomega.com

Leave a Reply