REDEFINING CONSTRUCTION STANDARDS: BIS CERTIFICATION FOR GLASS FIBRE REINFORCED GYPSUM PANELS AS PER IS 17400 WITH OMEGA QMS PVT. LTD.

INTRODUCTION

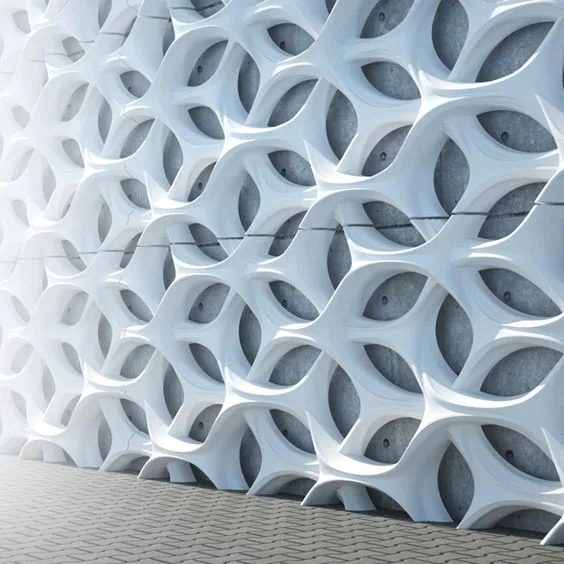

Glass Fibre Reinforced Gypsum (GFRG) panels are a revolutionary innovation in the construction industry, offering unparalleled strength, sustainability, and versatility. These panels, made primarily from gypsum plaster reinforced with glass fibres, are extensively used for constructing walls, roofs, and partitions. Their eco-friendly nature, combined with cost-effectiveness and energy efficiency, makes them a preferred choice for sustainable construction.

To ensure the quality, durability, and safety of GFRG panels, the Bureau of Indian Standards (BIS) has developed IS 17400: 2021. This standard defines the requirements for the materials, dimensions, manufacturing processes, and performance of GFRG panels. Achieving BIS certification as per IS 17400 is essential for manufacturers to validate their products’ compliance with national standards, enabling them to gain a competitive edge in the market.

Omega QMS Pvt. Ltd. plays a pivotal role in assisting manufacturers through the BIS certification process, ensuring a seamless journey from compliance to certification. This article delves into the specifics of IS 17400, the BIS certification process, and the expert guidance provided by Omega QMS.

SUMMARY OF IS 17400: GLASS FIBRE REINFORCED GYPSUM PANELS

IS 17400 is a comprehensive standard covering the specifications and quality requirements for GFRG panels used in building construction. Key highlights of the standard include:

- Scope: The standard applies to GFRG panels used in structural and non-structural applications such as walls, partitions, and ceilings. It encompasses both load-bearing (Class 1) and non-load-bearing (Class 2) panels.

- Material Requirements:

Gypsum: The primary material must meet the specified purity levels and mechanical properties, ensuring durability and fire resistance.

Glass Fibres: E-glass fibres with a diameter of 13 ± 2 µm and specified tensile properties must be used for reinforcement.

Water: Potable water, free from impurities, is mandated for the production process.

- Physical Properties:

Dimensions: Panels are manufactured in sizes up to 12 m × 3 m with precise tolerances to ensure uniformity.

Thickness: External flange thickness (15 mm) and internal rib thickness (20 mm) are critical parameters for structural stability.

Mechanical Strength:

Vertical load-bearing capacity: Minimum 160 kN/m for Class 1 panels and 90 kN/m for Class 2.

Fire resistance: 120 minutes of structural integrity and insulation.

BIS CERTIFICATION PROCESS FOR GFRG PANELS AS PER IS 17400

BIS offers a comprehensive certification scheme for GFRG panels, requiring manufacturers to undergo rigorous evaluation to demonstrate their compliance with IS 17400. Achieving this certification not only guarantees a high-quality product but also boosts market credibility, enhancing the manufacturer’s competitiveness.

OMEGA QMS PVT. LTD.: YOUR PARTNER IN BIS CERTIFICATION

Omega QMS Pvt. Ltd. specializes in guiding manufacturers through the often complex BIS certification process. Their comprehensive support includes:

- Application Submission: Assisting manufacturers in the precise preparation and submission of BIS certification applications.

- Factory Inspection Preparation: Helping set up essential quality control processes to ensure a smooth BIS inspection.

- Sample Testing Coordination: Managing the submission of product samples to BIS-authorized labs for compliance testing.

- Grant of Licence: Facilitating certification upon successful completion of testing.

For foreign manufacturers, Omega QMS also provides assistance with:

- Nominating Authorized Indian Representatives: Aiding in the appointment of local representatives for BIS.

- Signing Agreements: Guiding manufacturers through necessary agreements with BIS.

- Performance Bank Guarantees: Coordinating the submission of required financial guarantees.

- Ongoing Monitoring: Offering continuous support to maintain compliance through regular audits.

WHY PARTNER WITH OMEGA QMS PVT. LTD.?

Working with Omega QMS provides several significant advantages:

- Expertise: With over 30 years of experience in BIS regulations, their team of experts ensures a smooth and efficient certification process.

- Time and Cost Efficiency: Omega QMS helps reduce both the time and cost involved in securing BIS certification.

- Compliance Assurance: Their meticulous approach minimizes the risk of rejection, ensuring that products meet all necessary standards.

- Ongoing Support: Omega QMS provides continuous assistance to keep manufacturers up to date with evolving regulatory changes.

CONCLUSION AND FINAL THOUGHTS

Glass Fibre Reinforced Gypsum Panels represent the future of sustainable construction, combining structural strength with environmental benefits. Compliance with IS 17400: 2021 is crucial for manufacturers to validate their product’s quality, safety, and reliability.

With Omega QMS Pvt. Ltd., manufacturers can confidently navigate the complexities of the BIS certification process. Omega QMS’s expertise ensures that products not only meet but exceed the expectations set by national standards, empowering manufacturers to thrive in a competitive market.

By achieving BIS certification with Omega QMS’s guidance, manufacturers demonstrate their commitment to quality and sustainability, contributing to a robust and eco-friendly construction industry.

For your Certification needs pls contact:

OMEGA QMS PVT. LTD.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Email: info@globalomega.com, Phone: 011-41413939(100 lines)