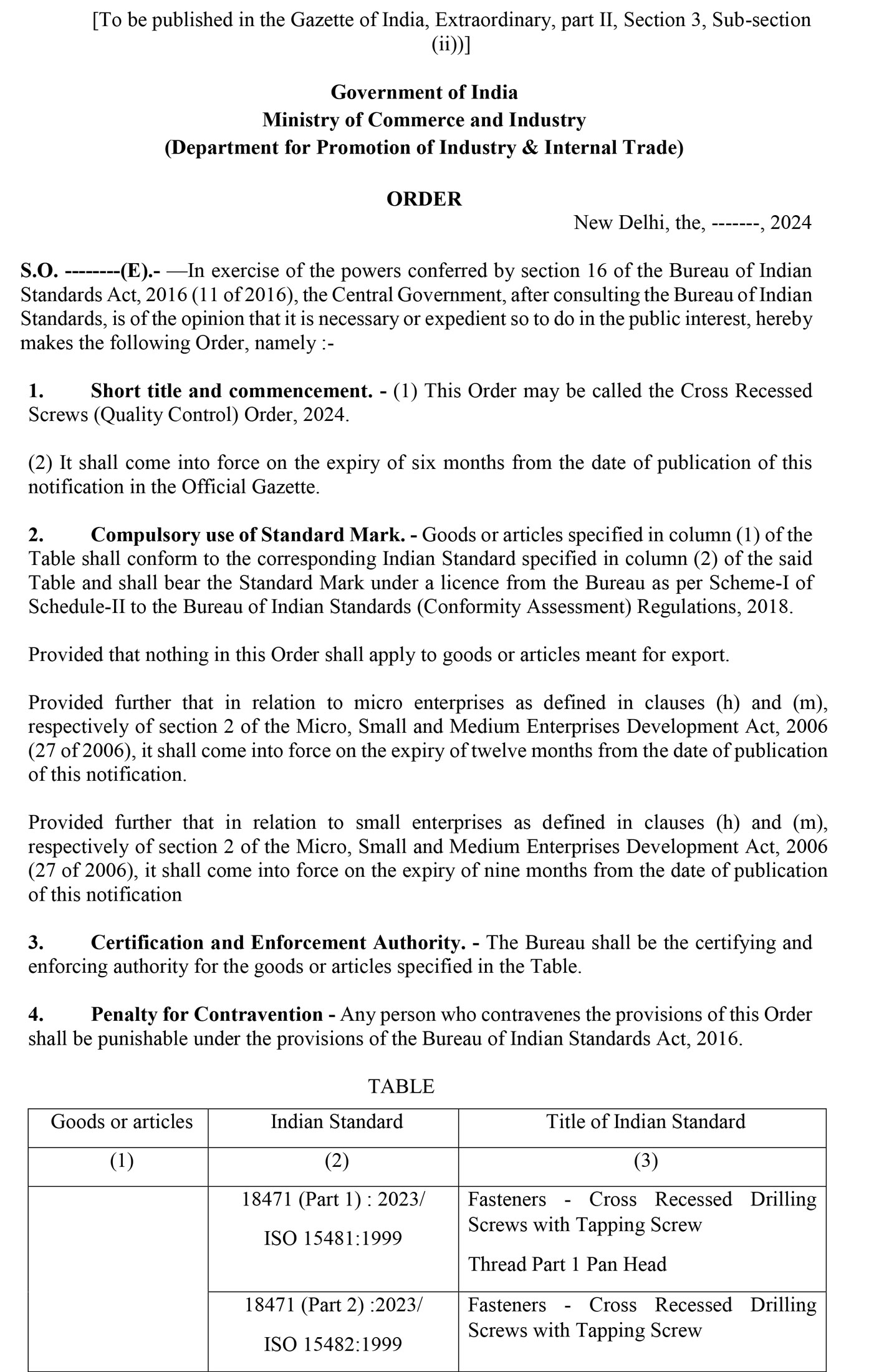

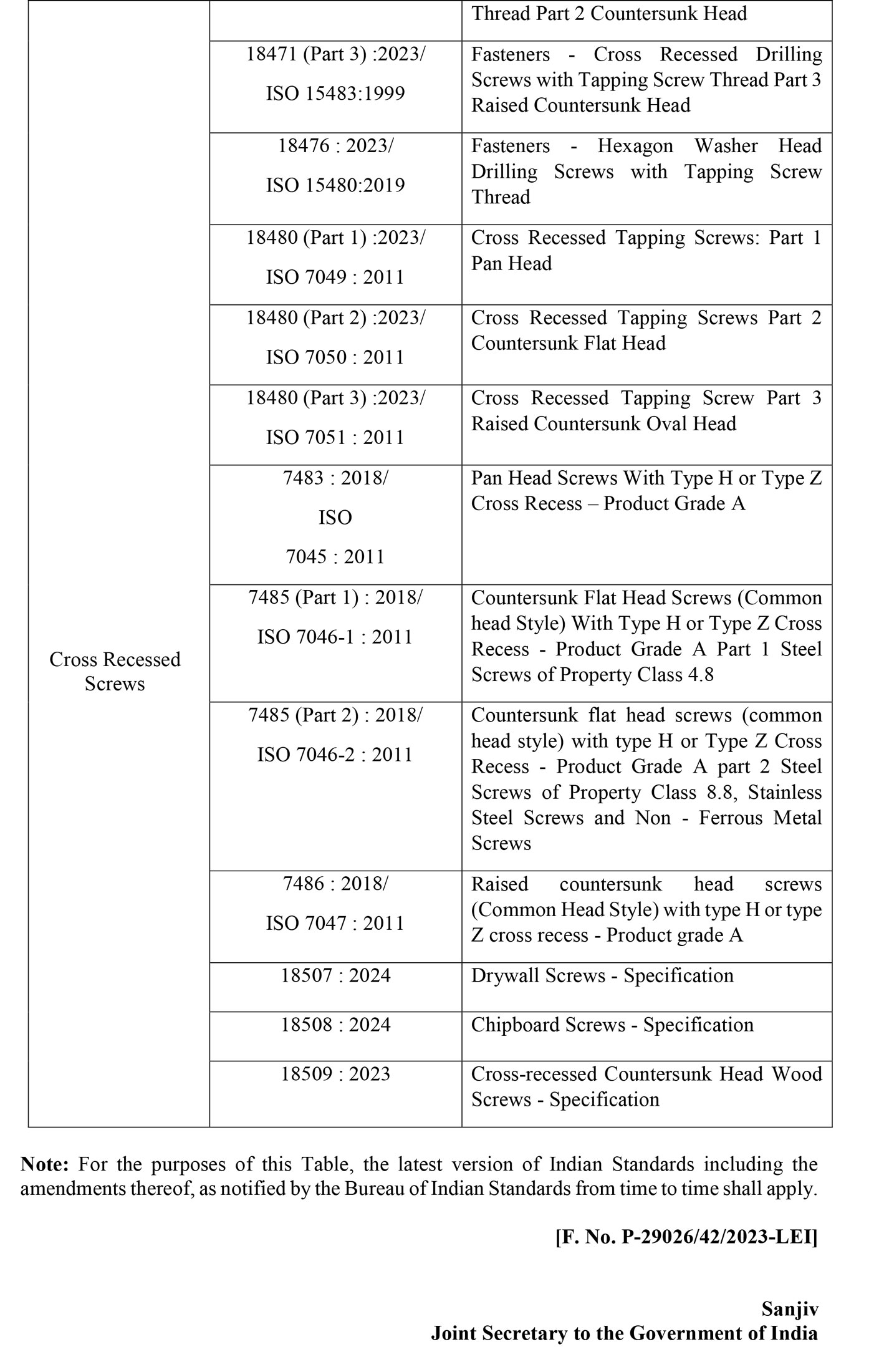

COMPREHENSIVE GUIDE TO BIS CERTIFICATION FOR CROSS RECESSED DRILLING SCREWS WITH TAPPING SCREW THREAD PART 1 PAN HEAD AS PER IS 18471 (PART 1) FROM OMEGA QMS PVT. LTD.

INTRODUCTION

Cross recessed drilling screws with tapping screw threads are vital components in numerous industrial applications. These fasteners, designed to create secure connections in materials such as metal, wood, and plastic without the need for pre-drilled holes, are indispensable for their efficiency and versatility. In this comprehensive guide, we will explore the Indian Standard IS 18471 (Part 1), explain the BIS certification scheme for these products, and highlight the essential role played by Omega QMS Pvt. Ltd. in aiding manufacturers to achieve certification.

SUMMARY OF INDIAN STANDARD IS 18471 (PART 1)

IS 18471 (Part 1) : 2023 aligns with the international standard ISO 15481 : 1999, ensuring global consistency in the quality and specifications of cross recessed pan head drilling screws. This standard is crucial for maintaining uniformity and reliability in manufacturing these fasteners. Key Features of the Standard :-

Scope Coverage: The standard specifies the characteristics of cross recessed pan head drilling screws with tapping screw threads from ST2,9 up to and including ST6,3.

Dimensions: The standard provides detailed dimensions and tolerances for various components of the screws. This includes parameters like thread size, head diameter, and length, ensuring precise manufacturing and interchangeability.

Dimensions: The standard provides detailed dimensions and tolerances for various components of the screws. This includes parameters like thread size, head diameter, and length, ensuring precise manufacturing and interchangeability.

Materials Steel Specifications: The screws are made from specified types of steel, meeting mechanical and functional property requirements as per ISO 10666.

Surface Finish: Requirements for plain and electroplated finishes are included, with electroplating standards outlined in ISO 4042.

Cross Recesses: The cross recesses on the screw heads, essential for compatibility with specific screwdrivers or bits, are defined in ISO 4757. This ensures secure and efficient driving of the screws.

Mechanical Properties: The screws must meet specific mechanical properties, such as hardness and tensile strength, ensuring they perform effectively under different conditions.

Tolerances: Tolerances for dimensions and mechanical properties are specified to ensure the screws meet precise manufacturing standards, as detailed in ISO 4759-1.

DRAFT QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued a draft Quality Control Order proposing to making it mandatory for all cross recessed screws as mentioned above to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence.

BIS CERTIFICATION SCHEME FOR IS 18471 (PART 1): 2023

The BIS certification marking is a symbol of conformity with Indian standards and regulations. For cross recessed screws falling under above mentioned Indian Standards, the BIS certification mark indicates that the product has undergone rigorous testing and evaluation processes to ensure compliance with specified parameters. This mark instils trust and confidence among consumers, indicating that the screws meets the requisite quality standards and is suitable for its intended application. It also facilitates market access, both domestically and internationally, by signalling adherence to recognized standards.

EXPERT GUIDANCE BY OMEGA QMS PVT LTD

Omega QMS Pvt Ltd offers comprehensive assistance to companies throughout the BIS certification process for cross recessed screws. Our team of experienced professionals provides end-to-end support, including:

Application Submission: We support manufacturers in preparing and submitting the BIS certification application to the Bureau of Indian Standards (BIS). Our team ensures that the application contains all necessary details about the product, its specifications, and the desired certification mark, thus facilitating a smooth application process.

Factory Inspection: Omega QMS prepares manufacturers for the factory inspection conducted by BIS. We assist in establishing and implementing quality control processes, infrastructure improvements, and ensuring adherence to relevant standards. Our goal is to help manufacturers showcase their commitment to quality during the inspection process. Omega also provided technical assistance

Sample Testing: We coordinate with client for the collection of product samples from the manufacturer’s facility. Omega QMS ensures that the samples are collected and submitted to authorized BIS laboratories or recognized testing centres for testing. We oversee the entire testing process to ensure compliance with BIS standards.

Grant of Licence: Upon receiving satisfactory test results and ensuring compliance with standards, Omega QMS liaises with BIS to facilitate the certification decision.

Additional Services to Foreign Manufacturers

Nominating Authorized Indian Representatives : Omega QMS Pvt. Ltd. assists foreign manufacturers in the FMCS of BIS by aiding them in nominating or providing authorized Indian representatives. This crucial step ensures that manufacturers have a local point of contact who can effectively liaise with BIS and handle regulatory matters on their behalf.

Signing Agreements with BIS: As a consultant for regulatory compliance, Omega QMS helps manufacturers in signing agreements with BIS as per stature requirement of BIS.

Submitting Performance Bank Guarantees: Omega QMS plays a crucial role in assisting manufacturers with the submission of performance bank guarantees as required by BIS. This entails coordinating with financial institution(s) and ensuring that all documentation is accurately prepared and submitted on time.

Regular Monitoring: Omega QMS continues to support manufacturers post-certification by assisting in regular monitoring activities conducted by BIS. We help manufacturers maintain compliance with quality control processes and standards through periodic audits. Our ongoing support ensures that certified products consistently meet BIS requirements.

Experienced Team : Omega QMS boasts a highly efficient team, spearheaded by a cadre of seasoned ex-Bureau of Indian Standards (BIS) officers, each boasting an impressive track record of over three decades in the industry. Their profound expertise and invaluable insights serve as the guiding force behind the seamless navigation of the certification process, ensuring meticulous adherence to the rigorous standards set forth by the BIS. With their wealth of experience, Omega QMS is well-equipped to deliver unparalleled excellence in quality management solutions, facilitating clients’ journeys towards achieving and maintaining BIS certifications with utmost precision and proficiency.

BENEFITS OF CHOOSING OMEGA QMS PVT LTD

Partnering with Omega QMS Pvt Ltd for BIS certification of cross recessed screws as per IS 18471 (Part 1) offers several advantages:

Expertise: Our team consists of seasoned professionals who possess extensive knowledge of regulatory requirements set forth by BIS. With over 30 years of experience in the field in BIS, our experts are well-equipped to navigate the intricacies of the certification process, ensuring a smooth and efficient experience for our clients.

Time and Cost Savings: We understand the importance of efficiency and cost-effectiveness for our clients. By leveraging our expertise and streamlined processes, we help reduce the time and resources required for certification. This not only saves our clients valuable time but also minimizes associated costs, making the certification process more affordable and accessible.

Assurance of Compliance: Compliance with regulatory standards is non-negotiable, especially in manufacturing where quality and safety are paramount. At Omega QMS, we leave no stone unturned in ensuring that all aspects of the certification process are handled meticulously. This meticulous approach minimizes the risk of rejections or delays, providing our clients with the assurance that their products meet the necessary standards.

Continuous Support: Our commitment to our clients extends beyond the certification process itself. We provide ongoing support to ensure that our clients maintain compliance and adapt to evolving regulatory changes. Whether its updates to standards or changes in regulatory requirements, our team is there to provide guidance and assistance every step of the way

CONCLUSION

The Indian Standard IS 18471 (Part 1) for cross recessed drilling screws is essential for ensuring that these fasteners meet stringent quality and performance criteria. The BIS certification scheme further guarantees that certified products are reliable and safe for use. Omega QMS Pvt. Ltd. plays a crucial role in guiding manufacturers through the complex BIS certification process, providing expert consultation, documentation assistance, pre-assessment, training, and liaison services. This collaborative effort between manufacturers, BIS, and Omega QMS enhances the quality and competitiveness of Indian-made fasteners in the global market, ensuring they meet the highest standards of excellence.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply