BIS CERTIFICATION FOR PRESSED BIMETALLIC HALF THRUST WASHERS: UNDERSTANDING IS 9764 (PART 2) WITH OMEGA QMS PVT. LTD.

INTRODUCTION: A Key Component in Load-Bearing Precision

In high-performance rotating machinery—be it in automotive engines, industrial compressors, or heavy equipment—thrust washers play an essential role. Among them, pressed bimetallic half thrust washers are crucial for managing axial loads while maintaining compact design and manufacturing efficiency.

To ensure quality, durability, and dimensional consistency, the Bureau of Indian Standards (BIS) mandates adherence to IS 9764 (Part 2), which specifies the features and tolerances for these washers. For manufacturers, achieving BIS certification under this standard ensures product credibility, market access, and regulatory compliance. And with Omega QMS Pvt. Ltd., the entire certification process becomes seamless, guided, and efficient.

SUMMARY OF IS 9764 (PART 2) PLAIN BEARINGS — THRUST WASHERS, PART 2: PRESSED BIMETALLIC HALF THRUST WASHERS

Scope : Specifies geometrical features, tolerances, and quality criteria. Applies to half washers made from bimetallic strip material, typically combining a steel backing with a bearing alloy lining (e.g., lead-based or tin-based). Does not cover main dimensional ranges, focusing instead on the characteristics critical to fit, function, and longevity.

Design Elements : Optional flat and locating lugs to prevent rotation and ensure axial alignment. Relief zones and scalloped toes to manage wear and improve oil retention.

Grooves for lubrication, with controlled dimensions and wall thickness.

Flatness : Flatness limits range from 0.10 mm to 0.15 mm based on washer diameter.

Critical to maintaining stable contact and reducing vibration.

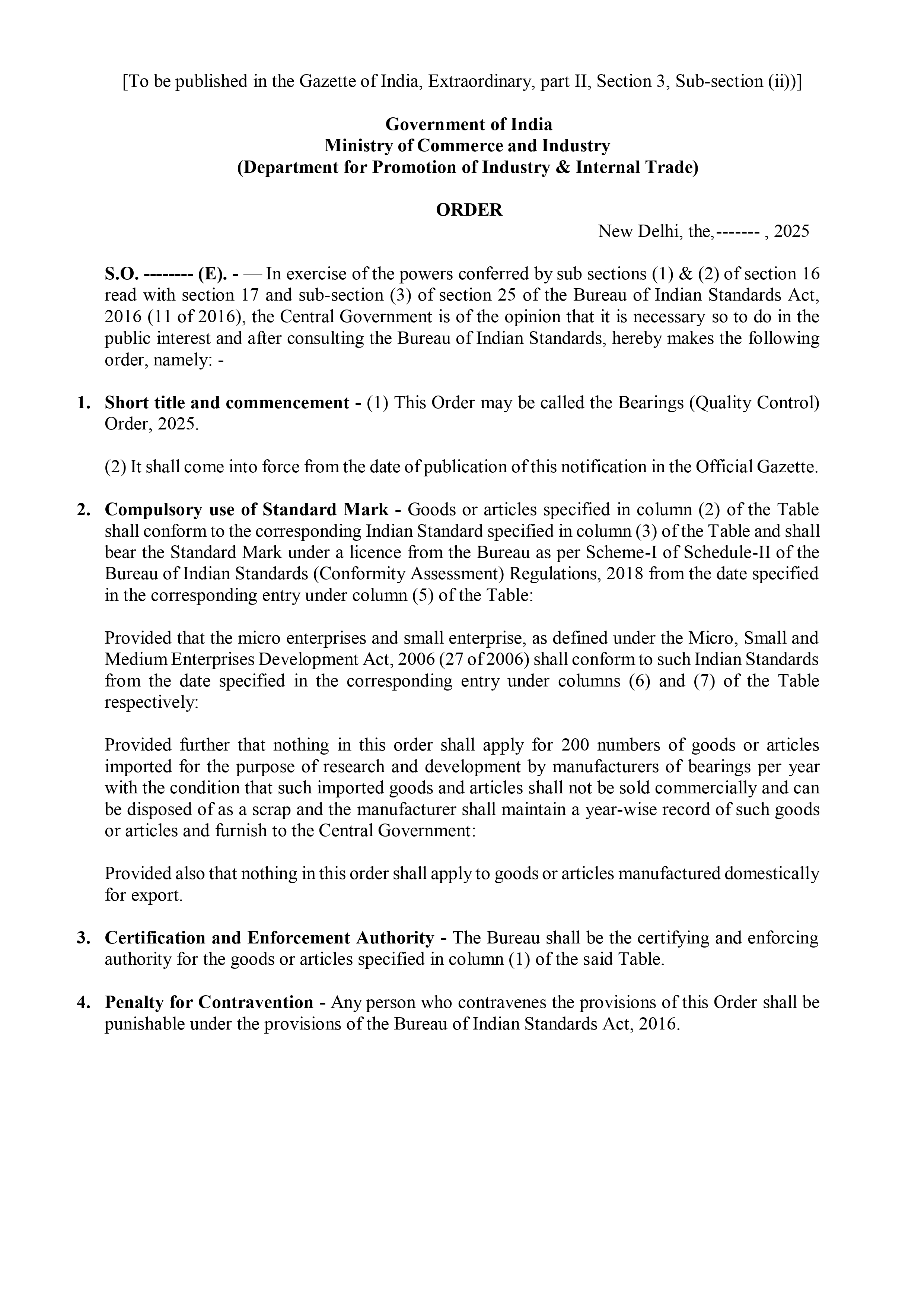

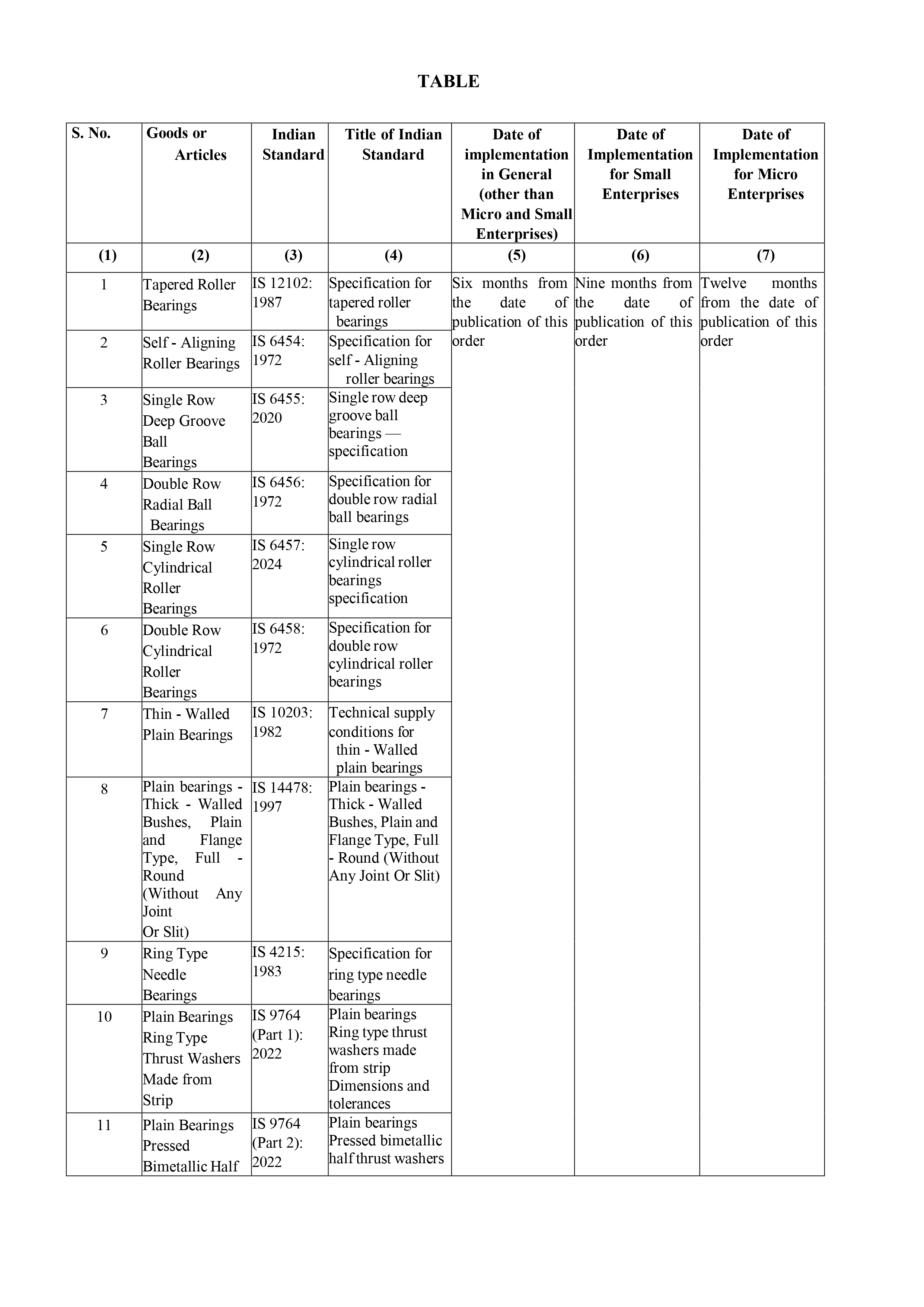

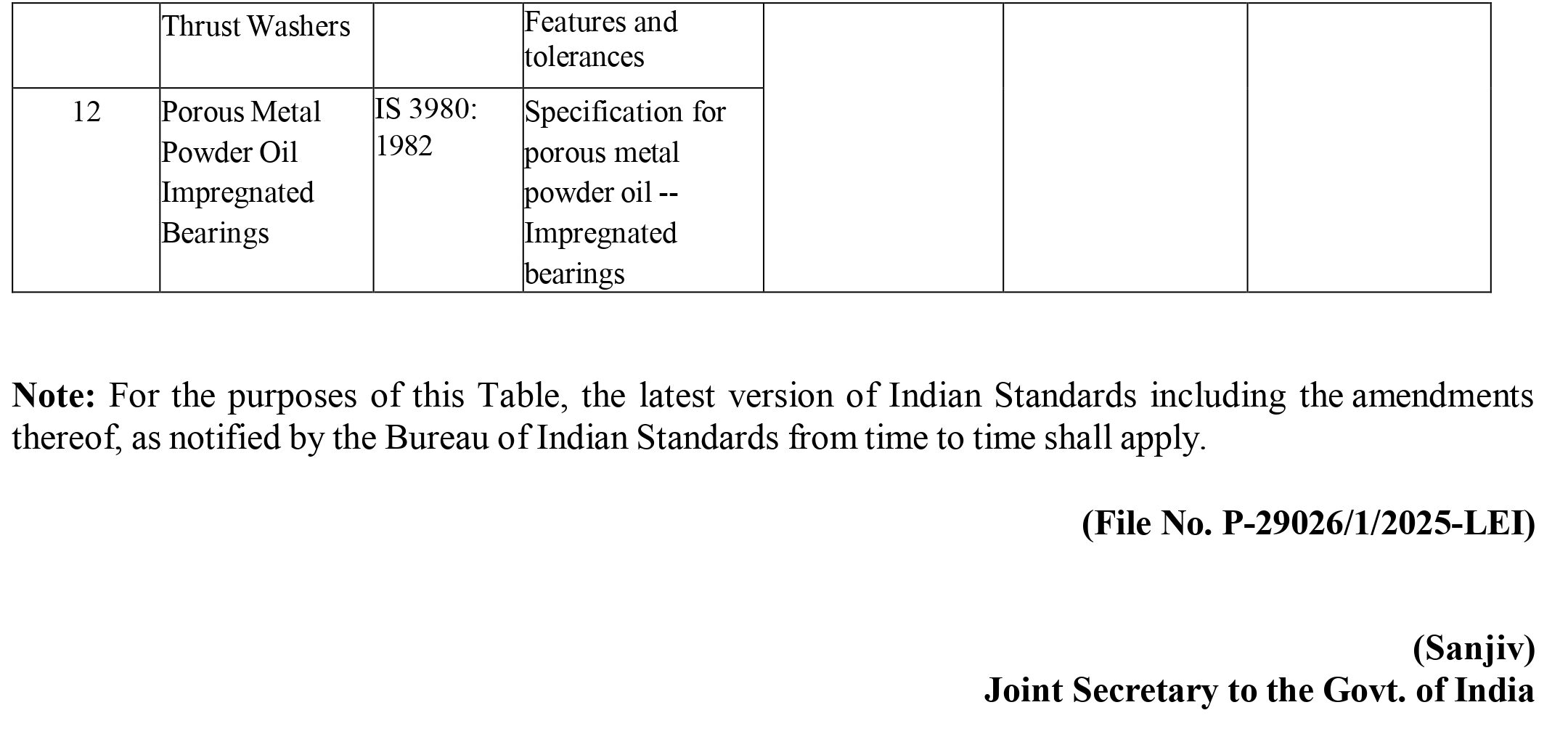

OVERVIEW OF THE QCO FOR BEARINGS

Quality Control Orders, or QCOs are a regulatory mechanism introduced by Ministry of Commerce under Bureau of Indian Standards (BIS) Act. They aim to ensure that products meet a minimum standard of quality and safety before being sold in the Indian market. For international traders, this means complying with BIS certification before exporting products like bearings to India.

India’s draft QCO for bearings emphasizes the quality standards and certification requirements for manufacturers, importers, and suppliers of these metals. The document mandates that all primary metals must conform to the relevant Indian Standards and manufacturers must obtain BIS certification before selling or distributing lead products in India.

BIS CERTIFICATION PROCESS FOR PRESSED BIMETALLIC HALF THRUST WASHERS UNDER IS 9764 (PART 2)

The BIS certification process for Pressed Bimetallic Half Thrust Washers ensures that the products conform to IS 9764 (Part 2) and meet stringent quality parameters. The certification follows a well-defined conformity assessment scheme under the BIS Act, 2016.

Steps Involved:

Application Submission: The manufacturer applies to BIS with product and factory details.

Product Testing: Samples are drawn from the production lot and tested for compliance with IS 9764 (Part 2) in BIS-recognized laboratories.

Factory Audit: BIS officers inspect the manufacturing process, quality control mechanisms, raw material traceability, and testing infrastructure.

Grant of License: If the product meets all specifications and the factory adheres to BIS standards, a license is granted to use the Standard Mark.

Ongoing Surveillance: BIS conducts periodic surveillance inspections and draws samples from the market or factory for re-testing.

HOW OMEGA QMS PVT. LTD. SUPPORTS MANUFACTURERS

Omega QMS Pvt. Ltd. is a leading consultancy specializing in helping manufacturers obtain and maintain BIS certification. For Pressed Bimetallic Half Thrust Washers under IS 9764 (Part 2), Omega QMS plays a vital role in simplifying the certification journey.

Services Provided:

Initial Gap Analysis: Assessing the manufacturer’s current compliance against IS 9764 (Part 2) and identifying areas for improvement.

Documentation Support: Preparation of technical documentation, and application papers required by BIS.

Factory Readiness Audits: Conducting mock audits to ensure the facility is ready for BIS inspection.

Liaison with BIS Authorities: Handling communication, application submission, and coordination for inspections and testing.

Post-Certification Support: Assistance in maintaining compliance during surveillance audits and for renewal of certification.

With Omega QMS by their side, manufacturers can focus on production while leaving the complex compliance process to the experts.

CONCLUSION

IS 9764 (Part 2) sets a clear benchmark for the manufacturing of pressed bimetallic half thrust washers, detailing the geometry, tolerances, material requirements, and marking criteria needed for high-performance applications. By achieving BIS certification, manufacturers signal their commitment to excellence, safety, and global quality norms.

FINAL THOUGHT

In the competitive world of component manufacturing, compliance isn’t optional—it’s essential. With IS 9764 (Part 2) as your guide and Omega QMS Pvt. Ltd. as your certification partner, you gain more than just a license—you gain industry trust, customer confidence, and a seat at the table of globally respected suppliers.

OMEGA QMS PVT. LTD.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Phone: 011-41413939(100 lines), Email: info@globalomega.com,

sales@globalomega.com, mktg@globalomega.com

Leave a Reply