BIS CERTIFICATION FOR PLAIN BEARINGS — RING TYPE THRUST WASHERS MADE FROM STRIP: A COMPLETE GUIDE TO IS 9764 (PART 1) WITH OMEGA QMS PVT. LTD.

INTRODUCTION

In the realm of high-speed rotating machinery, thrust forces often pose a critical challenge. Enter the ring-type thrust washer a compact, flat bearing component designed to handle axial loads and reduce friction between moving parts. These washers are widely used in automotive transmissions, pumps, compressors, and industrial machinery.

Manufactured primarily from strip material, ring-type thrust washers offer a cost-effective solution for space-constrained axial load applications. To ensure their performance and durability, manufacturers must adhere to stringent specifications outlined in the Indian Standard IS 9764 (Part 1): 2022. For those navigating the complex terrain of BIS certification, Omega QMS Pvt. Ltd. acts as a reliable partner in compliance and consultancy.

SUMMARY OF IS 9764 (PART 1) PLAIN BEARINGS — THRUST WASHERS, PART 1: RING TYPE THRUST WASHERS MADE FROM STRIP — DIMENSIONS AND TOLERANCES

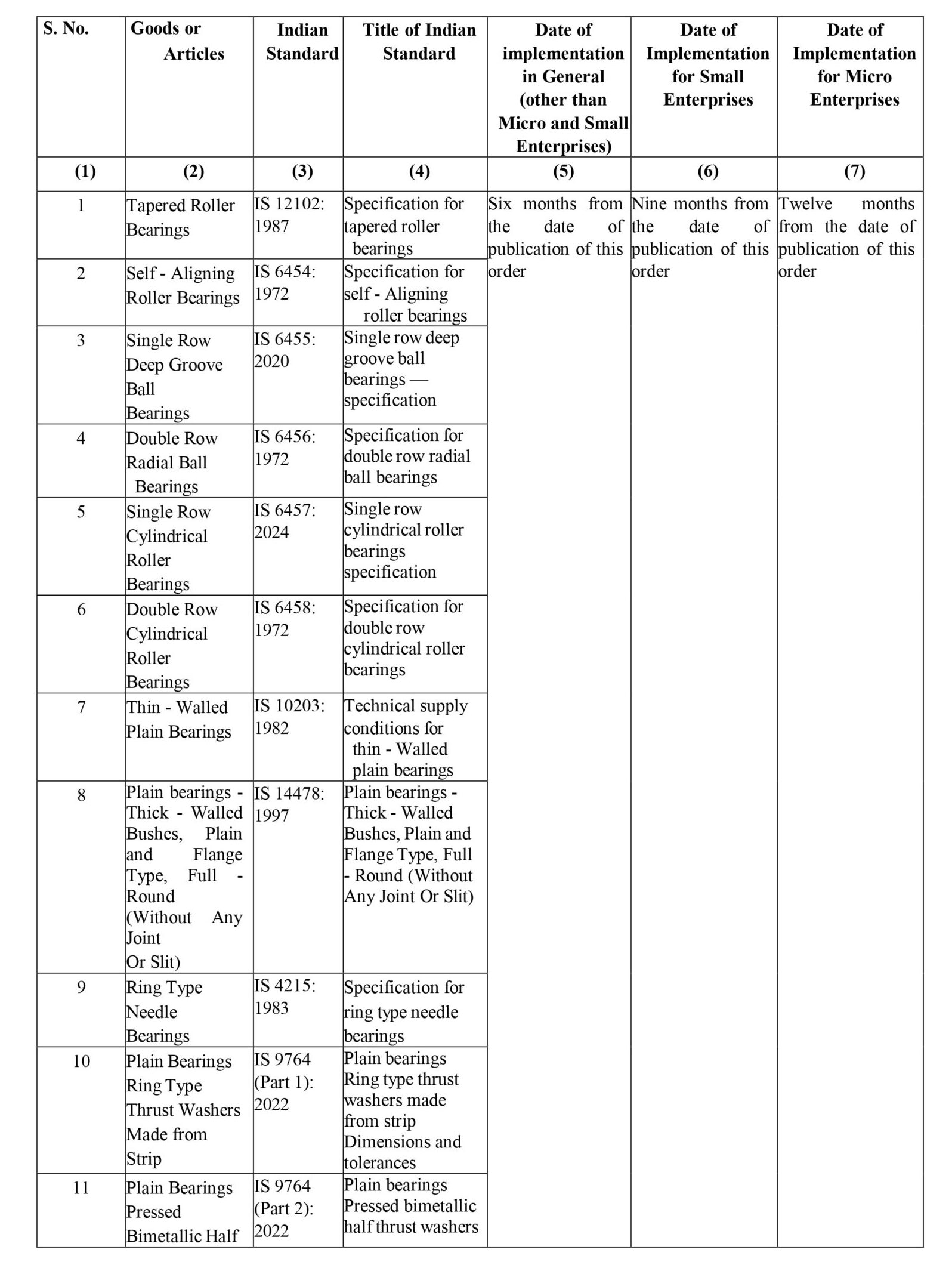

Scope: Applies to ring-type thrust washers made from strip material. Covers thrust washers with internal diameters from 6 mm to 80 mm.

Dimensions & Tolerances: The standard specifies:

Inside diameter (d) Outside diameter (D) Washer thickness (eT) Pitch circle diameter (C) Dowel hole diameter (F) Flatness limit (p)

Tolerances follow a G10 classification to ensure interchangeability and consistent performance.

Grooving and Surface Finish: Oil grooves may be included by agreement to enhance lubrication. Sharp edges must be removed for safety and operational efficiency.

Flatness is not specified for grooved washers due to potential distortion during the embossing process.

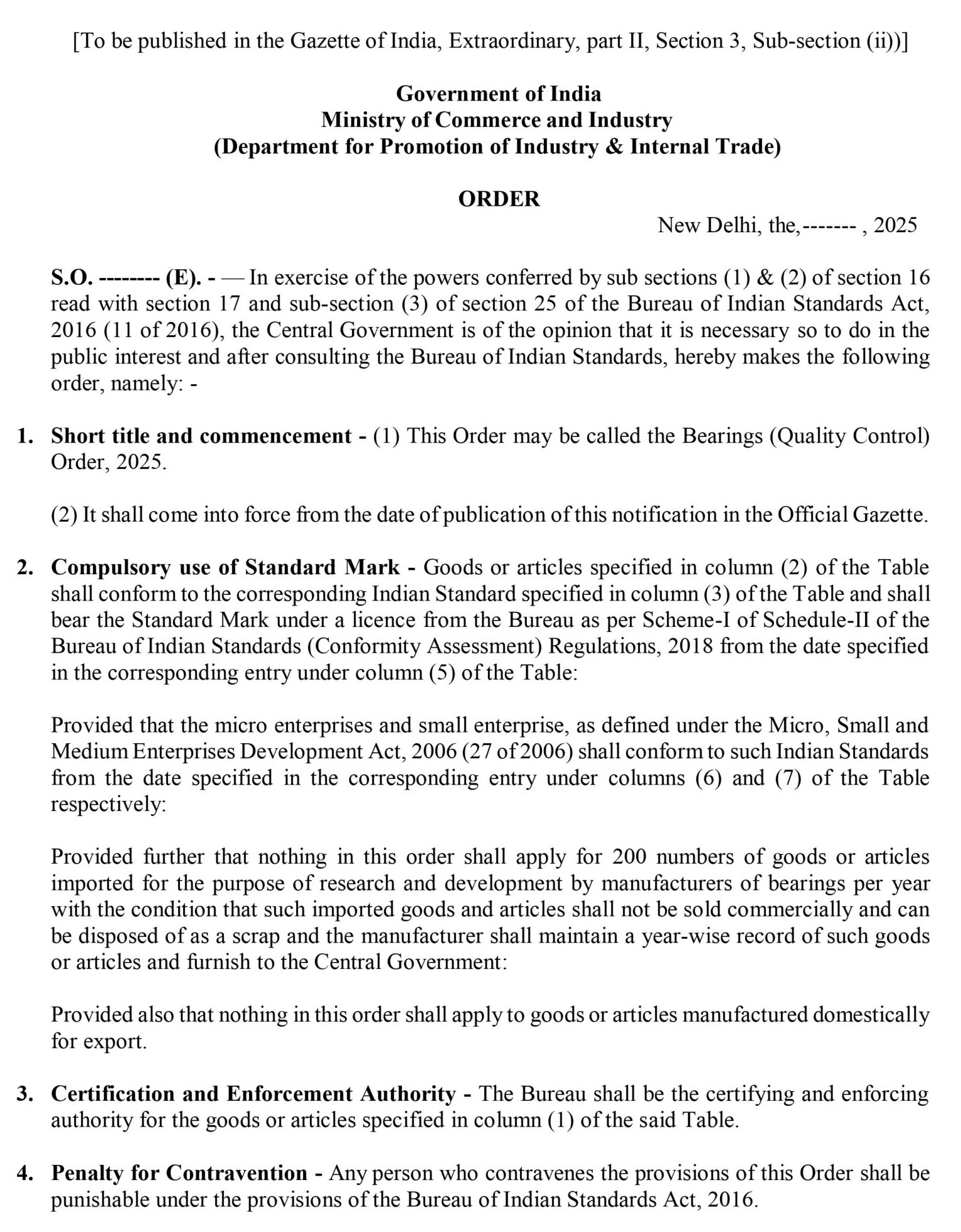

OVERVIEW OF THE QCO FOR BEARINGS

Quality Control Orders, or QCOs are a regulatory mechanism introduced by Ministry of Commerce under Bureau of Indian Standards (BIS) Act. They aim to ensure that products meet a minimum standard of quality and safety before being sold in the Indian market. For international traders, this means complying with BIS certification before exporting products like bearings to India.

India’s draft QCO for bearings emphasizes the quality standards and certification requirements for manufacturers, importers, and suppliers of these metals. The document mandates that all primary metals must conform to the relevant Indian Standards and manufacturers must obtain BIS certification before selling or distributing lead products in India.

BIS CERTIFICATION PROCESS FOR PLAIN BEARINGS — RING TYPE THRUST WASHERS MADE FROM STRIP UNDER IS 9764 (PART 1)

The BIS certification process for Plain Bearings — Ring Type Thrust Washers Made From Strip ensures that the products conform to IS 9764 (Part 1) and meet stringent quality parameters. The certification follows a well-defined conformity assessment scheme under the BIS Act, 2016.

Steps Involved:

Application Submission: The manufacturer applies to BIS with product and factory details.

Product Testing: Samples are drawn from the production lot and tested for compliance with IS 9764 (Part 1) in BIS-recognized laboratories.

Factory Audit: BIS officers inspect the manufacturing process, quality control mechanisms, raw material traceability, and testing infrastructure.

Grant of License: If the product meets all specifications and the factory adheres to BIS standards, a license is granted to use the Standard Mark.

Ongoing Surveillance: BIS conducts periodic surveillance inspections and draws samples from the market or factory for re-testing.

HOW OMEGA QMS PVT. LTD. SUPPORTS MANUFACTURERS

Omega QMS Pvt. Ltd. is a leading consultancy specializing in helping manufacturers obtain and maintain BIS certification. For Plain Bearings — Ring Type Thrust Washers Made From Strip under IS 9764 (Part 1), Omega QMS plays a vital role in simplifying the certification journey.

Services Provided:

Initial Gap Analysis: Assessing the manufacturer’s current compliance against IS 9764 (Part 1) and identifying areas for improvement.

Documentation Support: Preparation of technical documentation, and application papers required by BIS.

Factory Readiness Audits: Conducting mock audits to ensure the facility is ready for BIS inspection.

Liaison with BIS Authorities: Handling communication, application submission, and coordination for inspections and testing.

Post-Certification Support: Assistance in maintaining compliance during surveillance audits and for renewal of certification.

With Omega QMS by their side, manufacturers can focus on production while leaving the complex compliance process to the experts.

CONCLUSION

The Indian Standard IS 9764 (Part 1): 2022 provides a comprehensive framework for the design, production, and certification of ring-type thrust washers made from strip material. Adhering to this standard ensures product performance, interchangeability, and market acceptance — especially in regulated or high-precision sectors.

FINAL THOUGHT

As industries grow more quality-conscious and globally competitive, BIS certification under IS 9764 is more than a compliance step — it’s a strategic differentiator. With the expert support of Omega QMS Pvt. Ltd., manufacturers can navigate the certification process confidently, ensuring their products are trusted, tested, and technically sound.

OMEGA QMS PVT. LTD.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Phone: 011-41413939(100 lines), Email: info@globalomega.com,

sales@globalomega.com, mktg@globalomega.com

Leave a Reply