BIS CERTIFICATION FOR DOUBLE ROW CYLINDRICAL ROLLER BEARINGS: ALIGNING WITH IS 6458 AND THE EXPERTISE OF OMEGA QMS PVT. LTD.

Introduction: Power, Precision, and Performance in Rotation

When industries demand high radial load capacity and rigidity without compromising space efficiency, double row cylindrical roller bearings come to the rescue. These bearings are engineered to support intense loads while maintaining precise alignment and low friction, making them ideal for gearboxes, electric motors, compressors, and heavy-duty machinery.

Given their critical role in industrial performance, manufacturers must comply with stringent quality standards. The Bureau of Indian Standards (BIS) governs this compliance through IS 6458, which outlines the technical and dimensional requirements for these bearings. For companies aiming to obtain BIS certification efficiently and with confidence, Omega QMS Pvt. Ltd. offers expert consultancy and end-to-end assistance.

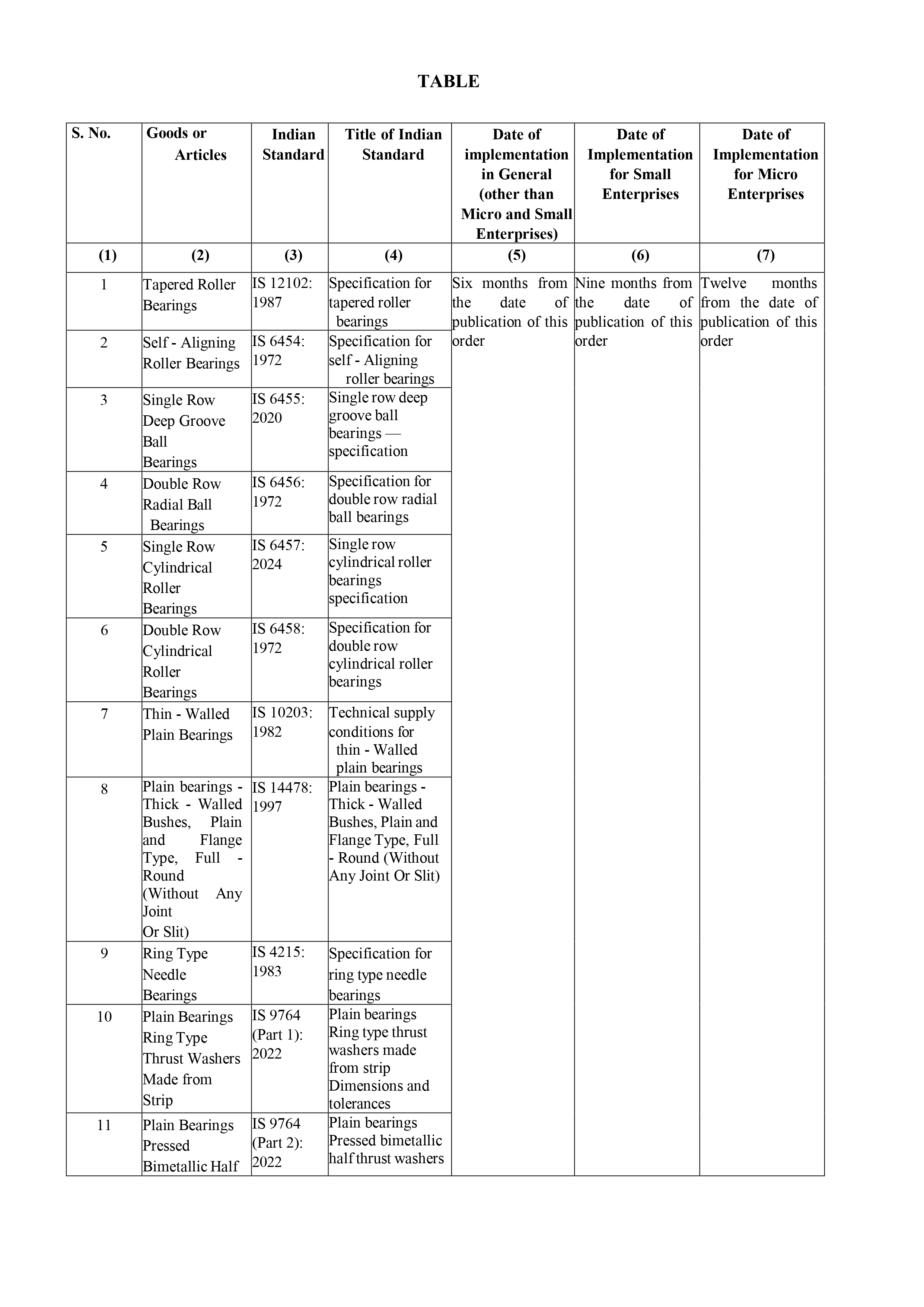

SUMMARY OF INDIAN STANDARD IS 6458 – SPECIFICATION FOR DOUBLE ROW CYLINDRICAL ROLLER BEARINGS

Scope: IS 6458 lays down the specifications for double row cylindrical roller bearings, encompassing:

- Non-locating bearings (support radial loads while allowing axial displacement),

- Two-direction locating bearings (control radial and axial loads in both directions).

This standard ensures interchangeability, consistent quality, and high performance across bearing types and industrial applications.

General Requirements: All other conditions such as materials, hardness, surface finish, and coating are governed by IS 6453 (technical supply conditions for rolling bearings).

Designation System: IS 6458 specifies a comprehensive and standardized designation system that includes:

- Bore diameter

- Configuration code

- Dimension series

- Tolerance class (e.g., P5)

- Radial clearance group (e.g., C2, C3)

- Special features like tapered bore (XK)

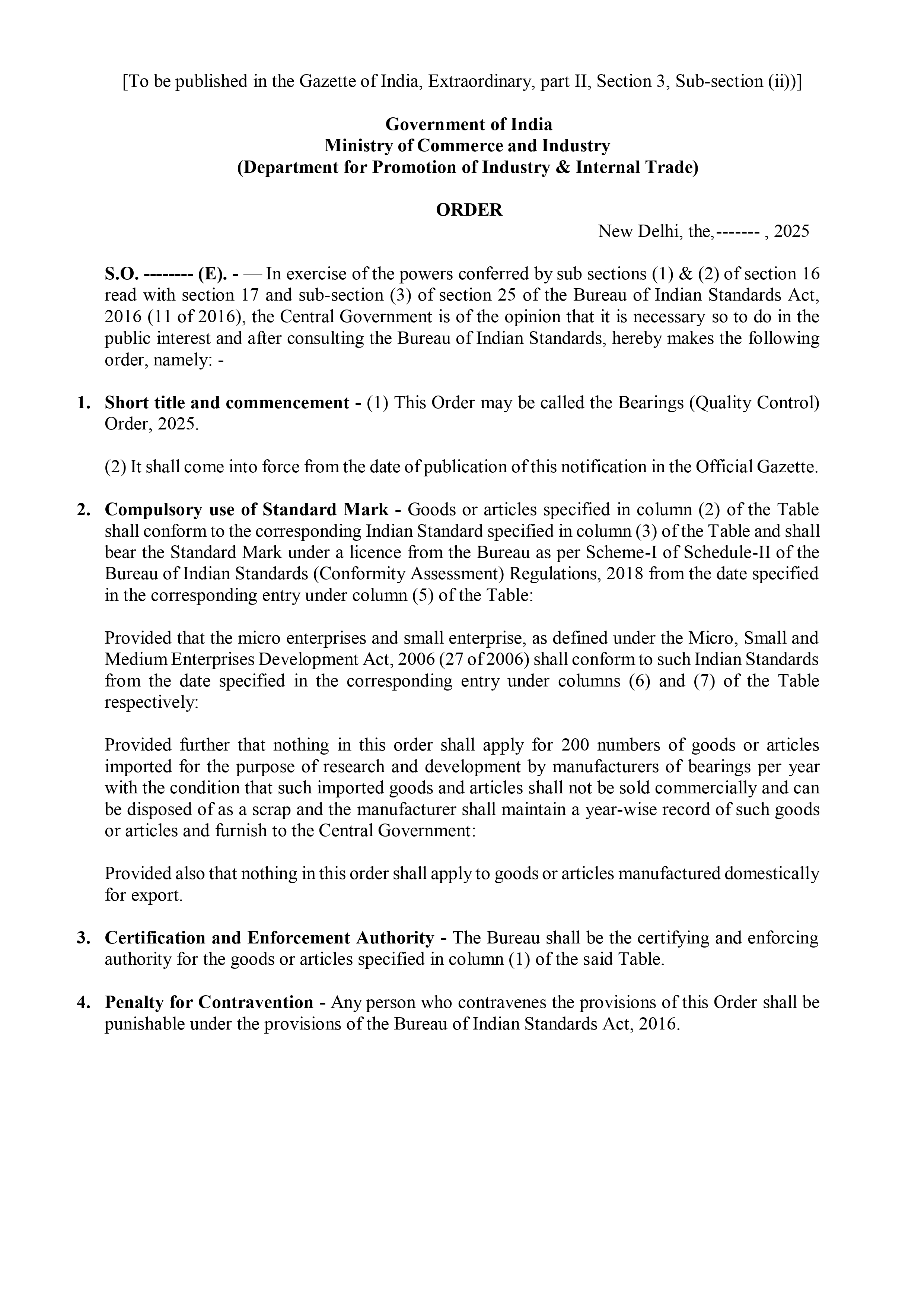

OVERVIEW OF THE QCO FOR BEARINGS

Quality Control Orders, or QCOs are a regulatory mechanism introduced by Ministry of Commerce under Bureau of Indian Standards (BIS) Act. They aim to ensure that products meet a minimum standard of quality and safety before being sold in the Indian market. For international traders, this means complying with BIS certification before exporting products like bearings to India.

India’s draft QCO for bearings emphasizes the quality standards and certification requirements for manufacturers, importers, and suppliers of these metals. The document mandates that all primary metals must conform to the relevant Indian Standards and manufacturers must obtain BIS certification before selling or distributing lead products in India.

BIS CERTIFICATION PROCESS FOR DOUBLE ROW RADIAL ROLLER BEARINGS UNDER IS 6458

The BIS certification process for tapered roller bearings ensures that the products conform to IS 6458 and meet stringent quality parameters. The certification follows a well-defined conformity assessment scheme under the BIS Act, 2016.

Steps Involved:

Application Submission: The manufacturer applies to BIS with product and factory details.

Product Testing: Samples are drawn from the production lot and tested for compliance with IS 6458 in BIS-recognized laboratories.

Factory Audit: BIS officers inspect the manufacturing process, quality control mechanisms, raw material traceability, and testing infrastructure.

Grant of License: If the product meets all specifications and the factory adheres to BIS standards, a license is granted to use the Standard Mark.

Ongoing Surveillance: BIS conducts periodic surveillance inspections and draws samples from the market or factory for re-testing.

HOW OMEGA QMS PVT. LTD. SUPPORTS MANUFACTURERS

Omega QMS Pvt. Ltd. is a leading consultancy specializing in helping manufacturers obtain and maintain BIS certification. For double row radial ball bearings under IS 6458, Omega QMS plays a vital role in simplifying the certification journey.

Services Provided:

Initial Gap Analysis: Assessing the manufacturer’s current compliance against IS 6458 and identifying areas for improvement.

Documentation Support: Preparation of technical documentation, and application papers required by BIS.

Factory Readiness Audits: Conducting mock audits to ensure the facility is ready for BIS inspection.

Liaison with BIS Authorities: Handling communication, application submission, and coordination for inspections and testing.

Post-Certification Support: Assistance in maintaining compliance during surveillance audits and for renewal of certification.

With Omega QMS by their side, manufacturers can focus on production while leaving the complex compliance process to the experts.

CONCLUSION

IS 6458:1972, with its clear dimensional, structural, and performance benchmarks, ensures that double row cylindrical roller bearings made in India are robust, precise, and globally competitive. BIS certification under this standard not only affirms product quality but also enhances customer trust and regulatory approval.

FINAL THOUGHT

In an industrial landscape where quality, durability, and compliance are non-negotiable, aligning your products with IS 6458 and achieving BIS certification is a strategic move. And with Omega QMS Pvt. Ltd. as your certification partner, success isn’t just possible — it’s guaranteed.

House, Rajendra Place, New Delhi-110008,

India, Phone: 011-41413939(100 lines), Email: info@globalomega.com,

sales@globalomega.com, mktg@globalomega.com

Leave a Reply