BIS CERTIFICATION FOR BUILDING HARDWARE: A COMPREHENSIVE GUIDE BY OMEGA QMS PVT. LTD.

INTRODUCTION

In construction and architecture, the reliability and safety of door hardware are crucial for ensuring a building’s security and functionality. The Bureau of Indian Standards (BIS) has established comprehensive standards for various door hardware components, including door closers, floor springs, rim latches, and door handles. This article explores the BIS certifications for specific door hardware components and emphasizes the importance of compliance with these standards.

INDIAN STANDARDS

IS 6343:1982 DOOR CLOSERS (PNEUMATICALLY REGULATED) FOR LIGHT DOORS WEIGHING UP TO 40 KG

This standard covers the requirements for door closers (pneumatically regulated) for use on light doors weighing up to 40 kg. The closer shall essentially consist of a cylinder made out of brass, aluminium or steel having a smooth drawn finish. The wall thickness shall not be less than 1 mm and one end of the cylinder shall permit access to the piston for servicing. An expanding member of a suitable material shall be provided for the piston to be maintained in positive contact with the tube for checking, and for sealing of the leakage. The speed of closing the door shall be controlled by means of covered helical torsion spring having adjustable tension. The closer shall be mounted on brackets having holes for not less than four attaching screws. Bearing pins and screws when assembled shall be secured in place. Besides other general requirements endurance test is specified in the standard.

This standard covers the requirements for door closers (pneumatically regulated) for use on light doors weighing up to 40 kg. The closer shall essentially consist of a cylinder made out of brass, aluminium or steel having a smooth drawn finish. The wall thickness shall not be less than 1 mm and one end of the cylinder shall permit access to the piston for servicing. An expanding member of a suitable material shall be provided for the piston to be maintained in positive contact with the tube for checking, and for sealing of the leakage. The speed of closing the door shall be controlled by means of covered helical torsion spring having adjustable tension. The closer shall be mounted on brackets having holes for not less than four attaching screws. Bearing pins and screws when assembled shall be secured in place. Besides other general requirements endurance test is specified in the standard.

IS 14912:2001 DOOR CLOSERS, CONCEALED TYPE (HYDRAULICALLY REGULATED)

This standard outlines the requirement for concealed type hydraulically operated door closers, fixed in concealed position within the thickness of the panel on vertical hinge type doors opening to one side only and not weighing more than 80 kg. The closing time shall be easily adjustable between 5 to 20s by means of regulating screws. Hydraulic oil filling shall work satisfactorily at all temperatures between 500C and –1O0C without requiring any change except adjustment of the regulating screw. The surface of the closers shall be clean, without sham edges, free from cracks, dents, burrs, or any other visible surface defects. Endurance test for 50000 cycles has been specified in the standard.

This standard outlines the requirement for concealed type hydraulically operated door closers, fixed in concealed position within the thickness of the panel on vertical hinge type doors opening to one side only and not weighing more than 80 kg. The closing time shall be easily adjustable between 5 to 20s by means of regulating screws. Hydraulic oil filling shall work satisfactorily at all temperatures between 500C and –1O0C without requiring any change except adjustment of the regulating screw. The surface of the closers shall be clean, without sham edges, free from cracks, dents, burrs, or any other visible surface defects. Endurance test for 50000 cycles has been specified in the standard.

IS 3564:1995 HYDRAULICALLY REGULATED DOOR CLOSERS

Door closers are made in several designs and types; some are made to be fixed in concealed positions while others are made to function in exposed positions; some work only on spring action while others require hydraulic check to arrest motion/speed m closing the door and to avert banging. This standard covers the hydraulic door closers of exposed type which are being widely used in the country and lays down the requirements for their manufacture and performance.

IS 6315:1992 FLOOR SPRINGS (HYDRAULICALLY REGULATED) FOR HEAVY DOORS

This standard covers the requirements for concealed type floor springs ( hydraulically regulated ) for vertical doors weighing not more than 125 kg. In case of doors consisting of more than one leaf the weight of each leaf shall not exceed 125 kg. The dimensions and tolerances of floor springs shall be as agreed to between the purchaser and the manufacturer. The oil-check shall work satisfactorily at all temperatures between 49°C and – 10oC without requiring any other change except by the adjustment of the capstan nut. The speed of closing the door shall be adjustable by means of a suitable controlling device. Tension of the spring shall be increased or decreased by turning the capstan nuts clockwise or anticlockwise. For exceptionally low temperature, the adjustment in the speed could be made by the change in the grade of oil. Besides material of construction of various components of floor spring standard also specifies the endurance requirement.

IS 1019:1974 RIM LATCHES

This standard lays down the requirements regarding material, dimensions, manufacture and finish of rim latches for general use. Rim latches shall be of the following two types: a) Type 1 – Rim latches which open when the handle is turned in one direction only. b) Type 2 – Rim latches which open when the’ handle is turned in any direction. The standard sizes of rim latches shall be 75, 100, 125 and 150 mm.

This standard lays down the requirements regarding material, dimensions, manufacture and finish of rim latches for general use. Rim latches shall be of the following two types: a) Type 1 – Rim latches which open when the handle is turned in one direction only. b) Type 2 – Rim latches which open when the’ handle is turned in any direction. The standard sizes of rim latches shall be 75, 100, 125 and 150 mm.

IS 208:2020 DOOR HANDLES

This standard lays down the requirements for materials, manufacture, dimensions and finish of door handles of the types that are commonly fixed to doors. Doors handle shall be of the following types according to the materials used: a) Type 1 — Cast b) Type 2 — Pressed oval c) Type 3 — Pressed half oval d) Type 4 — Fabricated. Materials for different types of door handles shall be as follows: a) Type 1 — Cast iron, malleable cast iron, cast brass, cast aluminium alloy or zinc alloy die casting. b) Type 2 and Type 3 — Mild steel or stainless steel, and c) Type 4 — Mild steel, stainless steel, brass or aluminium alloy.

This standard lays down the requirements for materials, manufacture, dimensions and finish of door handles of the types that are commonly fixed to doors. Doors handle shall be of the following types according to the materials used: a) Type 1 — Cast b) Type 2 — Pressed oval c) Type 3 — Pressed half oval d) Type 4 — Fabricated. Materials for different types of door handles shall be as follows: a) Type 1 — Cast iron, malleable cast iron, cast brass, cast aluminium alloy or zinc alloy die casting. b) Type 2 and Type 3 — Mild steel or stainless steel, and c) Type 4 — Mild steel, stainless steel, brass or aluminium alloy.

IS 4992:1975 DOOR HANDLES FOR MORTICE LOCK (VERTICAL TYPE)

This standard covers the requirements for door handles for operation of mortice locks (vertical type) covered in IS:2209. The door handles shall be normally made to the dimension and tolerances thereon, as given in the standard.

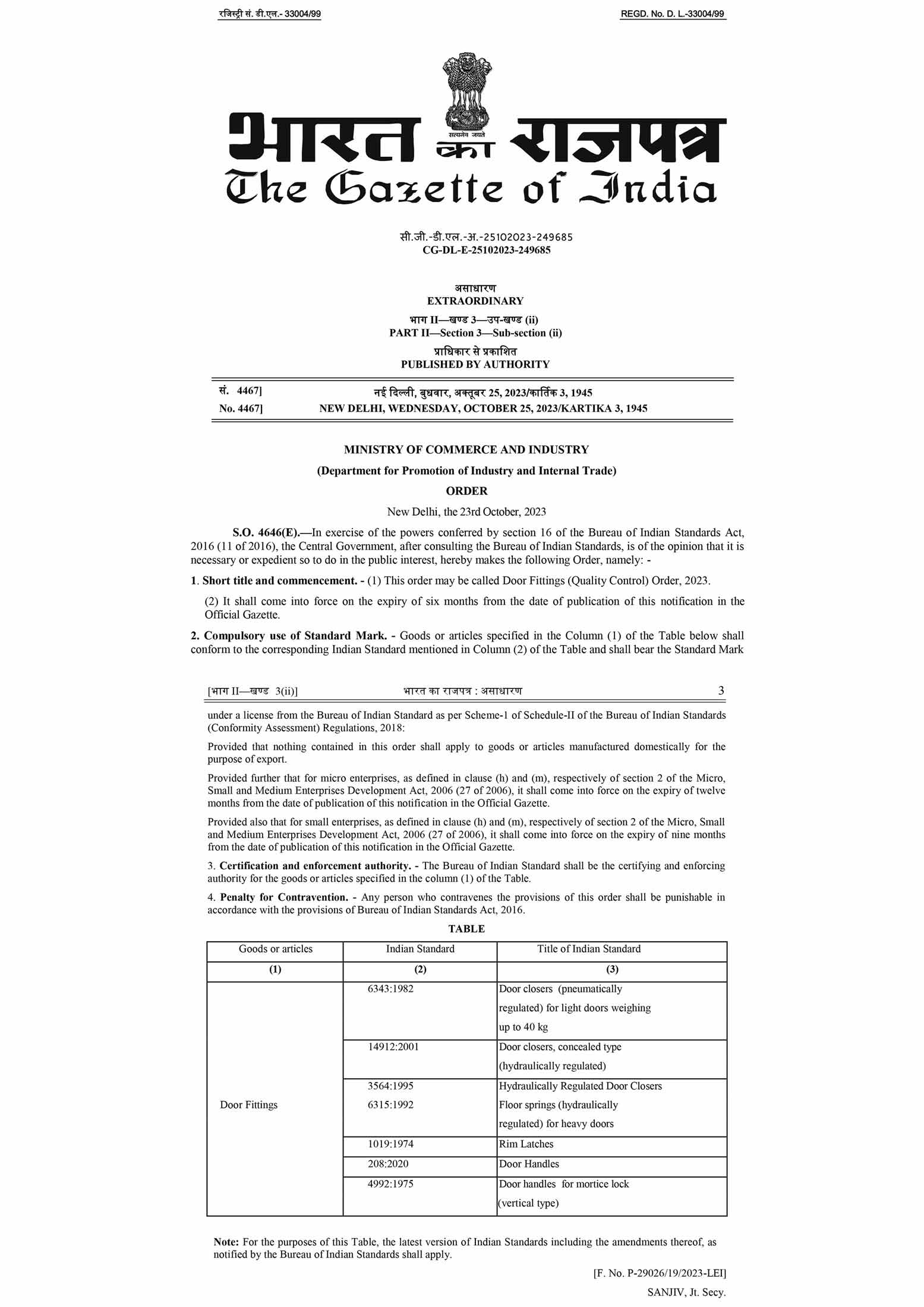

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 23 OCTOBER 2023 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for above hardware products to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence. In short, it has become obligatory for all the manufacturers of above mentioned hardwares, whether in India or overseas, to immediately apply for BIS licence and obtain a valid BIS certification licence.

BIS CERTIFICATION SCHEME

The BIS Standards listed above establishes a comprehensive framework encompassing various quality parameters that relevant hardware materials must adhere to. The Bureau of Indian Standards Certification Scheme is a vital framework established by the Indian government to ensure the quality, safety, and reliability of products available in the market. This scheme aims to safeguard consumer interests by setting stringent benchmarks and guidelines that products must meet before they can be deemed compliant. BIS certification covers a wide range of industries and products, encompassing the entire gamut of industrial and manufacturing activity.

EXPERT GUIDANCE BY OMEGA QMS PVT LTD

Omega QMS Pvt Ltd offers comprehensive assistance to companies throughout the BIS certification process for door hardware. Our team of experienced professionals provides end-to-end support, including:

Application Submission: We support manufacturers in preparing and submitting the BIS certification application to the Bureau of Indian Standards (BIS). Our team ensures that the application contains all necessary details about the product, its specifications, and the desired certification mark, thus facilitating a smooth application process.

Factory Inspection: Omega QMS prepares manufacturers for the factory inspection conducted by BIS. We assist in establishing and implementing quality control processes, infrastructure improvements, and ensuring adherence to relevant standards. Our goal is to help manufacturers showcase their commitment to quality during the inspection process. Omega also provided technical assistance

Sample Testing: We coordinate with client for the collection of product samples from the manufacturer’s facility. Omega QMS ensures that the samples are collected and submitted to authorized BIS laboratories or recognized testing centres for testing. We oversee the entire testing process to ensure compliance with BIS standards.

Grant of Licence: Upon receiving satisfactory test results and ensuring compliance with standards, Omega QMS liaises with BIS to facilitate the certification decision.

Additional Services to Foreign Manufacturers

Nominating Authorized Indian Representatives : Omega QMS Pvt. Ltd. assists foreign manufacturers in the FMCS of BIS by aiding them in nominating or providing Authorized Indian Representatives. This crucial step ensures that manufacturers have a local point of contact who can effectively liaise with BIS and handle regulatory matters on their behalf.

Signing Agreements with BIS: As a consultant for regulatory compliance, Omega QMS helps manufacturers in signing agreements with BIS as per stature requirement of BIS.

Submitting Performance Bank Guarantees: Omega QMS plays a crucial role in assisting manufacturers with the submission of performance bank guarantees as required by BIS. This entails coordinating with financial institution(s) and ensuring that all documentation is accurately prepared and submitted on time.

Regular Monitoring: Omega QMS continues to support manufacturers post-certification by assisting in regular monitoring activities conducted by BIS. We help manufacturers maintain compliance with quality control processes and standards through periodic audits. Our ongoing support ensures that certified products consistently meet BIS requirements.

Experienced Team: Omega QMS boasts a highly efficient team, spearheaded by a cadre of seasoned ex-Bureau of Indian Standards (BIS) officers, each boasting an impressive track record of over three decades in the industry. Their profound expertise and invaluable insights serve as the guiding force behind the seamless navigation of the certification process, ensuring meticulous adherence to the rigorous standards set forth by the BIS. With their wealth of experience, Omega QMS is well-equipped to deliver unparalleled excellence in quality management solutions, facilitating clients’ journeys towards achieving and maintaining BIS certifications with utmost precision and proficiency.

BENEFITS OF CHOOSING OMEGA QMS PVT LTD

Partnering with Omega QMS Pvt Ltd for BIS certification of Door Hardware as per abovementioned Indian standards offers several advantages:

Expertise: Our team consists of seasoned professionals who possess extensive knowledge of regulatory requirements set forth by BIS. With over 30 years of experience in the field in BIS, our experts are well-equipped to navigate the intricacies of the certification process, ensuring a smooth and efficient experience for our clients.

Time and Cost Savings: We understand the importance of efficiency and cost-effectiveness for our clients. By leveraging our expertise and streamlined processes, we help reduce the time and resources required for certification. This not only saves our clients valuable time but also minimizes associated costs, making the certification process more affordable and accessible.

Assurance of Compliance: Compliance with regulatory standards is non-negotiable, especially in chemicals manufacturing where quality and safety are paramount. At Omega QMS, we leave no stone unturned in ensuring that all aspects of the certification process are handled meticulously. This meticulous approach minimizes the risk of rejections or delays, providing our clients with the assurance that their products meet the necessary standards.

Continuous Support: Our commitment to our clients extends beyond the certification process itself. We provide ongoing support to ensure that our clients maintain compliance and adapt to evolving regulatory changes. Whether it’s updates to standards or changes in regulatory requirements, our team is there to provide guidance and assistance every step of the way

CONCLUSION

In conclusion, BIS certification is pivotal in ensuring the quality, safety, and compliance of door hardware components. With Omega QMS Pvt Ltd as a trusted partner, businesses can confidently embark on the certification journey, knowing that their products will meet the stringent standards set by the Bureau of Indian Standards.

For your Certification needs pls contact info@globalomega.com, 011-41413939 (100 lines)

For your Certification needs pls contact info@globalomega.com, 011-41413939 (100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Comment (1)

This is the most comprehensive article I’ve found on this subject. Great job.