ACHIEVING BIS CERTIFICATION FOR SELF CONTAINED DRINKING WATER COOLERS: A COMPREHENSIVE GUIDE BY OMEGA QMS PVT LTD

INTRODUCTION

Water coolers are ubiquitous appliances in homes, offices, schools, and public spaces across India, providing access to safe and refreshing drinking water. Ensuring the energy efficiency and performance of these devices is paramount for both environmental sustainability and consumer satisfaction. The Indian Standard IS 1475 (Part 1) sets forth guidelines for self-contained drinking water coolers, focusing on energy consumption and performance metrics to promote efficiency and quality in the market.

UNDERSTANDING IS 1475 (PART 1): 2001

IS 1475 (Part 1) delineates the constructional requirements, standard sizes, testing methods, and installation guidelines for self-contained drinking water coolers. It encompasses units powered by electrically driven vapor compression refrigerating machines with air-cooled condensers. Water coolers are classified into pressure type and storage type. Pressure type coolers may include bubblers or faucets for dispensing water, while storage type coolers can store water within the same container or employ external bottles or containers. Coolers are rated under specified conditions, including ambient temperature of 35.0°C, inlet water temperature of 30.0°C, and maximum outlet water temperature of 13.5°C. Recommended sizes and capacity ratings for pressure and storage type water coolers are provided in tables based on cooling capacity, storage capacity, and minimum static head. Type tests, production routine tests, and acceptance tests are outlined, including insulation resistance tests, high voltage tests, cooling capacity rating tests, and maximum operating condition tests. Procedures for sample selection, approximation, and test conditions are detailed, along with instrument requirements and accuracy standards.

IS 1475 (Part 1) delineates the constructional requirements, standard sizes, testing methods, and installation guidelines for self-contained drinking water coolers. It encompasses units powered by electrically driven vapor compression refrigerating machines with air-cooled condensers. Water coolers are classified into pressure type and storage type. Pressure type coolers may include bubblers or faucets for dispensing water, while storage type coolers can store water within the same container or employ external bottles or containers. Coolers are rated under specified conditions, including ambient temperature of 35.0°C, inlet water temperature of 30.0°C, and maximum outlet water temperature of 13.5°C. Recommended sizes and capacity ratings for pressure and storage type water coolers are provided in tables based on cooling capacity, storage capacity, and minimum static head. Type tests, production routine tests, and acceptance tests are outlined, including insulation resistance tests, high voltage tests, cooling capacity rating tests, and maximum operating condition tests. Procedures for sample selection, approximation, and test conditions are detailed, along with instrument requirements and accuracy standards.

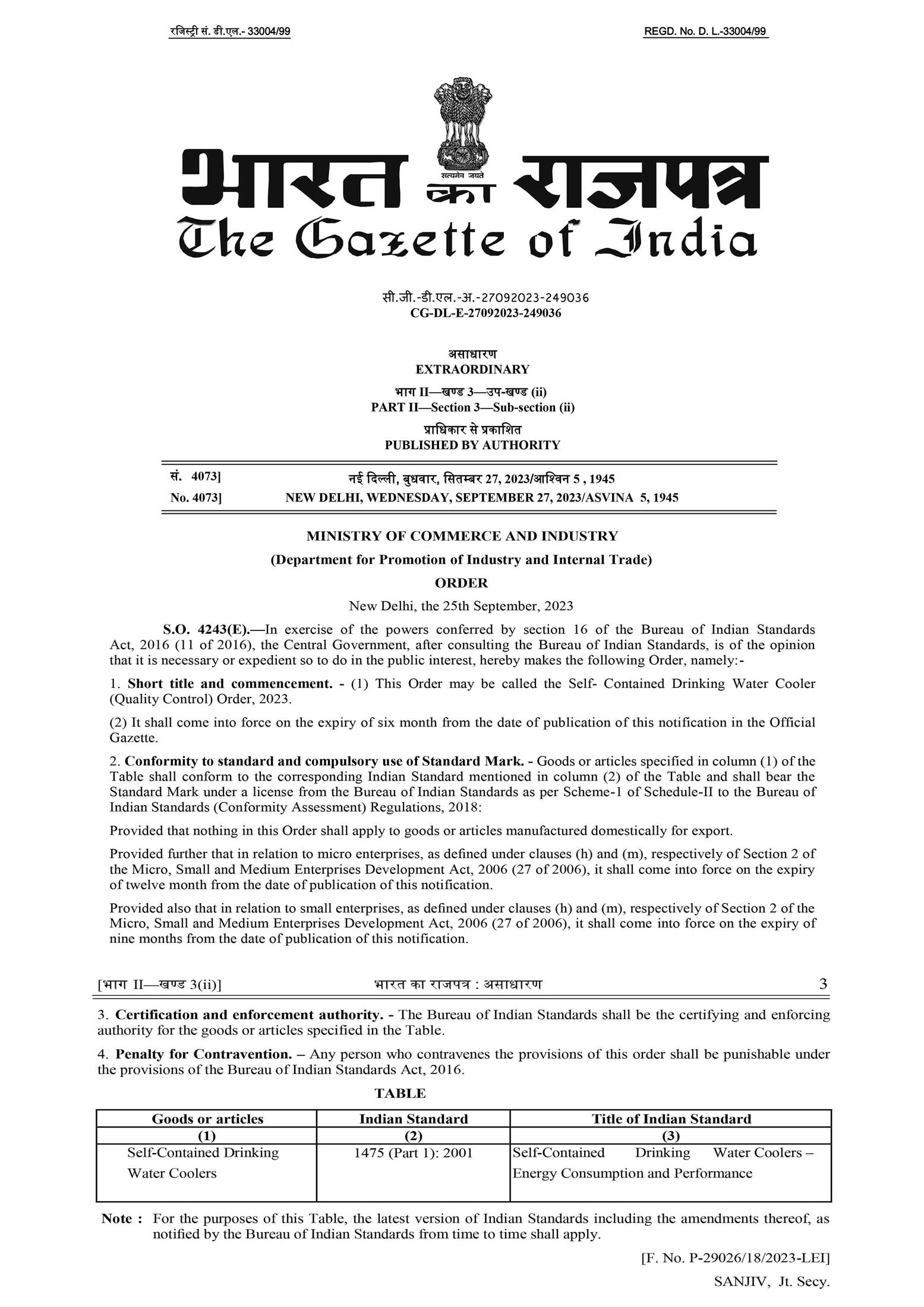

QUALITY CONTROL ORDER (TECHNICAL REGULATION) ISSUED BY THE DEPARTMENT FOR PROMOTION OF INDUSTRY AND INTERNAL TRADE, MINISTRY OF COMMERCE AND INDUSTRY, GOVT. OF INDIA ON 25 SEPTEMBER 2023 FOR MANDATORY BIS CERTIFICATION

The DPIIT, Ministry of Commerce & Industry, Govt. of India, has issued an order, making it mandatory for all fasteners to be used in India, whether manufactured in India or imported from foreign countries, shall mandatorily carry the Standard Mark of the Bureau of Indian Standards under a valid BIS licence. In short, it has become obligatory for all the manufacturers of fasteners, whether in India or overseas, to immediately apply for BIS licence and obtain a valid BIS certification licence.

IMPORTANCE OF BIS CERTIFICATION

Manufacturers of self-contained drinking water coolers must adhere to IS 1475 (Part 1) to obtain certification from the Bureau of Indian Standards (BIS). The BIS Certification Mark signifies compliance with Indian standards and assures consumers of product quality and safety. Water coolers certified under IS 1475 (Part 1) bear specific markings, including the manufacturer’s name, model and serial number, refrigerant details, supply characteristics, cooling capacity, wiring diagram, full load current, and maximum energy consumption under test conditions.

EXPERT GUIDANCE BY OMEGA QMS PVT LTD

Omega QMS Pvt Ltd offers comprehensive assistance to companies throughout the BIS certification process for self-contained water coolers. Our team of experienced professionals provides end-to-end support, including:

Standard Identification: Omega QMS assists manufacturers in identifying the relevant BIS standard applicable to their product category. Leveraging our expertise, we ensure that manufacturers understand the specific quality and performance requirements outlined in the standards.

Application Submission: We support manufacturers in preparing and submitting the BIS certification application to the Bureau of Indian Standards (BIS). Our team ensures that the application contains all necessary details about the product, its specifications, and the desired certification mark, thus facilitating a smooth application process.

Factory Inspection: Omega QMS prepares manufacturers for the factory inspection conducted by BIS. We assist in establishing and implementing quality control processes, infrastructure improvements, and ensuring adherence to relevant standards. Our goal is to help manufacturers showcase their commitment to quality during the inspection process.

Sample Testing: We coordinate with client for the collection of product samples from the manufacturer’s facility. Omega QMS ensures that the samples are collected and submitted to authorized BIS laboratories or recognized testing centers for testing. We oversee the entire testing process to ensure compliance with BIS standards.

Certification Decision: Upon receiving satisfactory test results and ensuring compliance with standards, Omega QMS liaises with BIS to facilitate the certification decision.

Regular Monitoring: Omega QMS continues to support manufacturers post-certification by assisting in regular monitoring activities conducted by BIS. We help manufacturers maintain compliance with quality control processes and standards through periodic audits. Our ongoing support ensures that certified products consistently meet BIS requirements.

Experienced Team: Omega QMS employs an efficient team led by a group of ex-BIS officers, each with over 30 years of experience in the field. Their expertise and insights ensure smooth navigation of the certification process and adherence to BIS standards.

BENEFITS OF CHOOSING OMEGA QMS PVT LTD

Partnering with Omega QMS Pvt Ltd for BIS certification of PVC pipes offers several advantages:

Expertise: Our team consists of seasoned professionals who possess extensive knowledge of regulatory requirements, including those set forth by BIS. With over 30 years of experience in the field in BIS , our experts are well-equipped to navigate the intricacies of the certification process, ensuring a smooth and efficient experience for our clients.

Time and Cost Savings: We understand the importance of efficiency and cost-effectiveness for our clients. By leveraging our expertise and streamlined processes, we help reduce the time and resources required for certification. This not only saves our clients valuable time but also minimizes associated costs, making the certification process more affordable and accessible.

Assurance of Compliance: Compliance with regulatory standards is non-negotiable, especially in industries like water cooler manufacturing where quality and safety are paramount. At Omega QMS, we leave no stone unturned in ensuring that all aspects of the certification process are handled meticulously. This meticulous approach minimizes the risk of rejections or delays, providing our clients with the assurance that their products meet the necessary standards.

Continuous Support: Our commitment to our clients extends beyond the certification process itself. We provide ongoing support to ensure that our clients maintain compliance and adapt to evolving regulatory changes. Whether it’s updates to standards or changes in regulatory requirements, our team is there to provide guidance and assistance every step of the way.

CONCLUSION

In conclusion, adherence to Indian Standard IS 1475 (Part 1) is essential for ensuring the energy efficiency and performance of self-contained drinking water coolers. BIS certification marking signifies compliance with quality and performance standards, instilling confidence in consumers and enhancing market competitiveness. With the support of consultancy firms like Omega QMS Pvt. Ltd., manufacturers can efficiently navigate the certification process, improve product quality, and contribute to a sustainable future.

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply