ACHIEVING BIS CERTIFICATION FOR POLYPROPYLENE 3, 4, 8, AND 12-STRAND ROPES AS PER IS 5175: A COMPREHENSIVE GUIDE BY OMEGA QMS PVT. LTD.

INTRODUCTION

Polypropylene ropes are known for their lightweight, durability, and resistance to chemicals, making them ideal for use in marine, industrial, and construction applications. Whether used for mooring, lifting, or general-purpose tasks, ensuring that these ropes meet the highest safety and quality standards is critical. The Bureau of Indian Standards (BIS) has set forth detailed guidelines under IS 5175 to regulate the quality and performance of Polypropylene 3-, 4-, 8-, and 12-strand ropes. For manufacturers, obtaining BIS certification under IS 5175 not only ensures compliance with national standards but also enhances market credibility and consumer trust.

This article provides a detailed overview of IS 5175, the BIS certification process for Polypropylene ropes, and the essential role Omega QMS Pvt. Ltd. plays in assisting manufacturers in achieving certification.

SUMMARY OF IS 5175: POLYPROPYLENE 3-, 4-, 8-, AND 12-STRAND ROPES

IS 5175:2022 is the Indian Standard that outlines the requirements for Polypropylene ropes, specifically for three construction types: split film, monofilament, and multifilament. These ropes are used in various industrial and general service applications due to their lightweight nature, high tenacity, and resistance to degradation by UV light and chemicals.

Key aspects of IS 5175 include:

Material Composition: The standard differentiates between Polypropylene split film, monofilament (PP2), and high-tenacity multifilament (PP3). These materials must meet specific quality and strength criteria for each rope type.

Rope Construction: IS 5175 details the acceptable constructions for Polypropylene ropes, including 3-strand hawser-laid, 4-strand shroud-laid, 8-strand braided, and 12-strand braided types. The different construction methods ensure optimal strength and flexibility for different applications.

Performance Requirements: The ropes must meet strict performance criteria, including minimum breaking strength (MBS), linear density, and elongation properties. These performance standards ensure that the ropes are strong and reliable for industrial use.

Physical Properties: The linear density, or mass per unit length, and the breaking strength are specified in detail for both dry and wet conditions. The standard provides specific tables outlining the acceptable values for each type and size of rope.

UV Resistance and Durability: Polypropylene fibres are known to degrade under prolonged exposure to sunlight. IS 5175 mandates that the ropes be treated or stabilized to ensure protection from UV radiation, ensuring long-term durability.

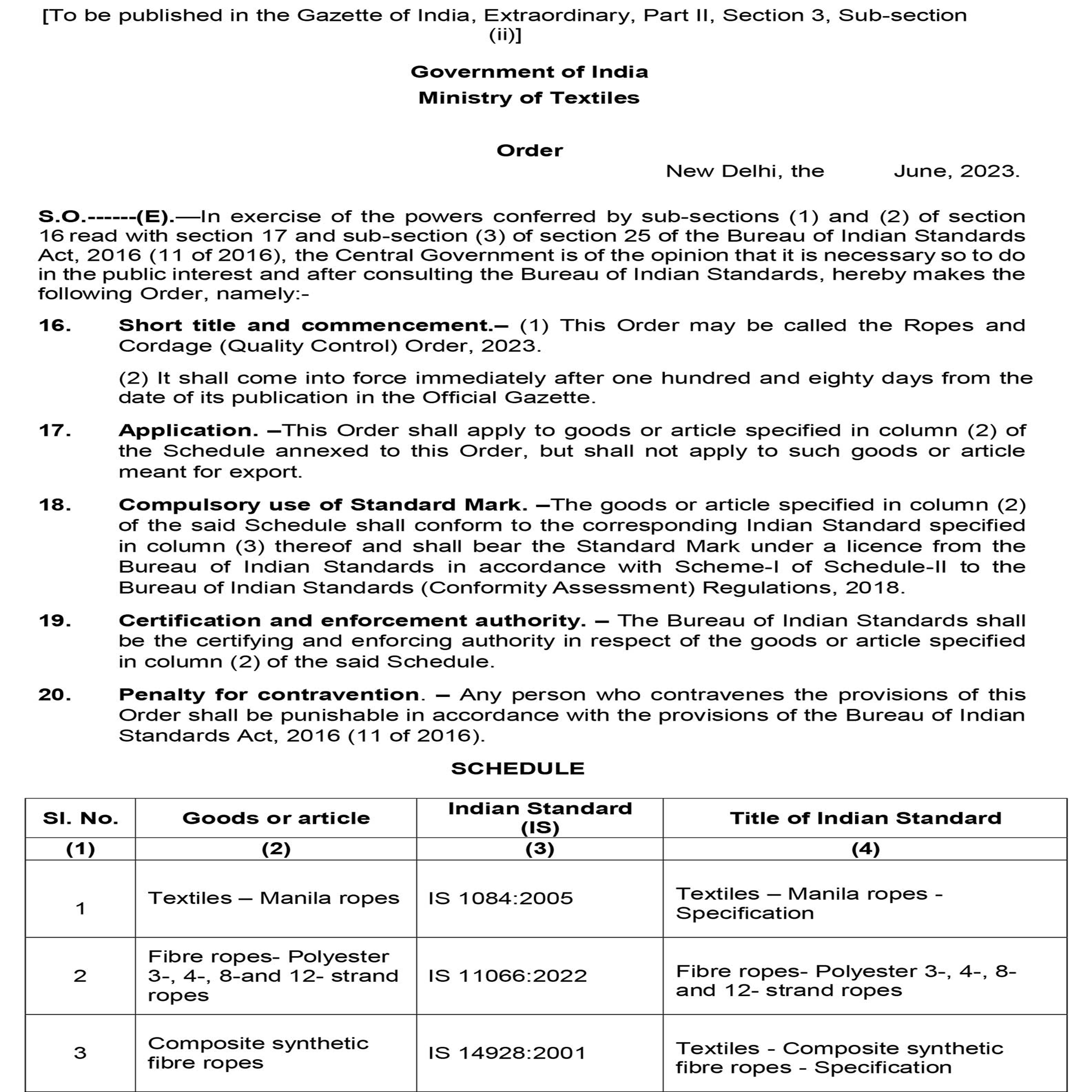

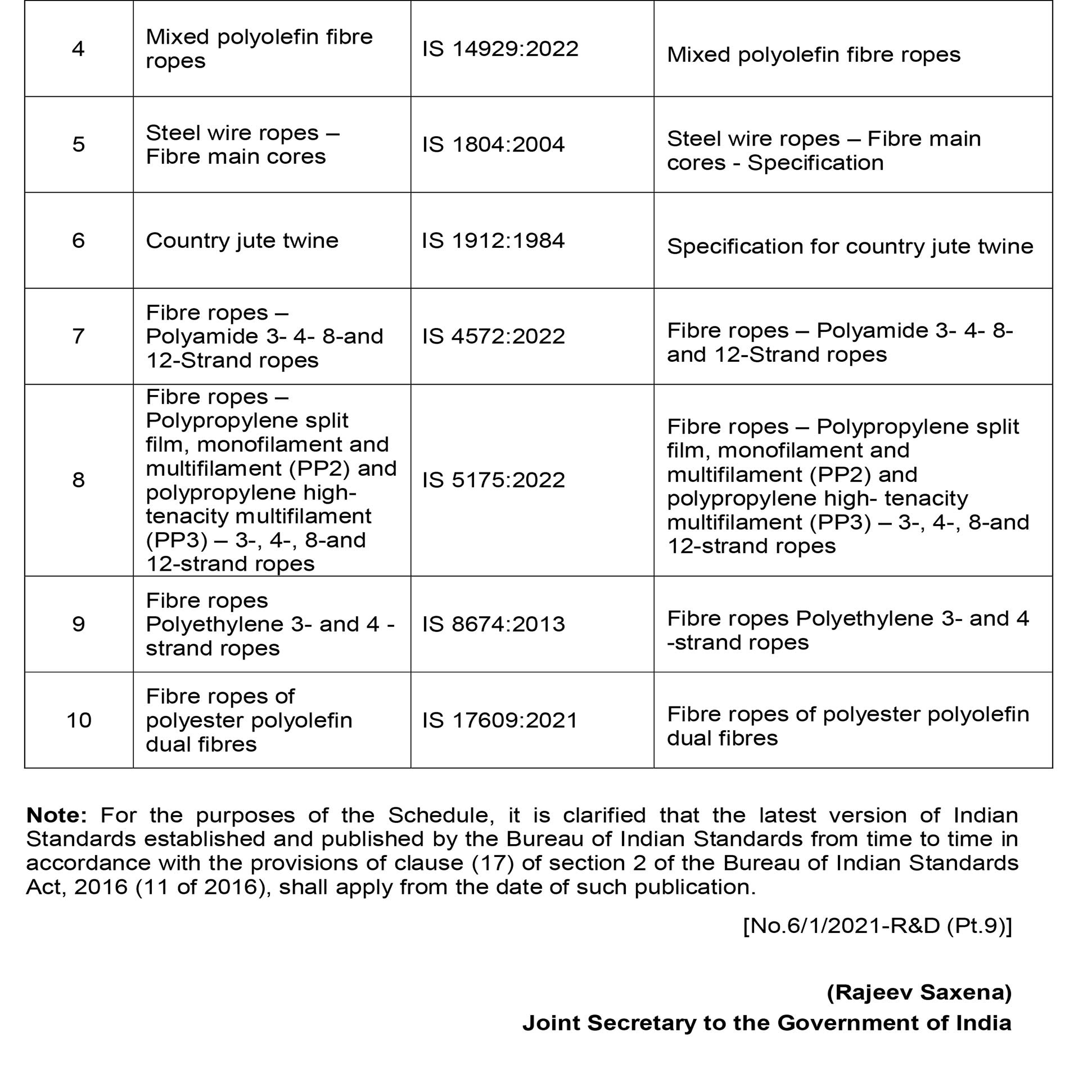

DRAFT QUALITY CONTROL ORDER (TECHNICAL REGULATION)

The Indian government proposes mandatory BIS certification for all 3,4,8 and 12 Strand Polypropylene Ropes, whether produced domestically or imported, to ensure it meets the standards set by IS 5175.

BIS CERTIFICATION OF 3, 4, 8 AND 12 STRAND POLYPROPYLENE ROPES AS PER IS 5175

BIS offers a certification scheme for 3, 4, 8 and 12 Strand Polypropylene Ropes, where manufacturers undergo rigorous evaluation to demonstrate compliance with IS 5175. This certification is a mark of quality, enhancing market acceptance and competitiveness.

OMEGA QMS PVT. LTD.: YOUR PARTNER IN BIS CERTIFICATION

Omega QMS Pvt. Ltd. provides comprehensive support throughout the BIS certification process for these 3, 4, 8 and 12 Strand Polypropylene Ropes, including:

Application Submission: Assisting in the accurate preparation and submission of the BIS certification application.

Factory Inspection Preparation: Helping manufacturers prepare for BIS inspections by setting up necessary quality control processes.

Sample Testing Coordination: Managing the submission of product samples to BIS-authorized labs for compliance testing.

Grant of Licence: Facilitating the certification process once testing is successfully completed.

For international manufacturers, Omega QMS also assists with:

Nominating Authorized Indian Representatives: Helping in appointing local representatives for BIS.

Signing Agreements: Guiding manufacturers through the necessary agreements with BIS.

Performance Bank Guarantees: Coordinating the submission of required financial guarantees.

Regular Monitoring: Providing ongoing support to ensure continuous compliance through periodic audits.

BENEFITS OF PARTNERING WITH OMEGA QMS PVT. LTD.

Working with Omega QMS offers several key advantages:

Expertise: A team of seasoned professionals with over 30 years of experience in BIS regulations ensures a smooth certification process.

Time and Cost Efficiency: Omega QMS helps reduce the time and cost associated with obtaining BIS certification.

Compliance Assurance: Their thorough approach minimizes the risk of rejections, ensuring products meet all required standards.

Ongoing Support: Continuous assistance to help manufacturers stay compliant with evolving regulatory changes.

CONCLUSION AND FINAL THOUGHTS

BIS certification for Polypropylene 3-, 4-, 8-, and 12-strand ropes under IS 5175 is essential for manufacturers who want to ensure that their products meet the highest standards of quality, safety, and performance. Certification not only confirms compliance with national standards but also enhances market credibility, providing a competitive edge in a demanding industry.

Partnering with Omega QMS Pvt. Ltd. simplifies the certification process, allowing manufacturers to focus on production while ensuring that their products meet BIS standards. From application submission to post-certification support, Omega QMS offers expert guidance every step of the way, ensuring a smooth and successful certification journey.

In a market where safety and quality are paramount, having BIS-certified Polypropylene ropes signifies a commitment to excellence, backed by the trusted support of Omega QMS Pvt. Ltd

For your Certification needs pls contact info@globalomega.com 011-41413939(100 lines)

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Leave a Reply