BIS CERTIFICATION FOR COMBINATION SIDE CUTTING PLIERS AS PER IS 3650 1981: A COMPRESENSIVE GUIDE BY OMEGA. QMS. PVT. LTD

INTRODUCTION

Combination side-cutting pliers are fundamental tools in a variety of industries, including electrical, mechanical, and general engineering work. These versatile tools are used for gripping, bending, cutting, and manipulating wires and other materials. To ensure durability and performance, combination side-cutting pliers must adhere to strict quality standards. The Bureau of Indian Standards (BIS) provides certification for these tools to ensure they meet the requirements outlined in IS 3650. In this article, we will explore the key aspects of IS 3650, the BIS certification process for combination side-cutting pliers, and the role of Omega QMS Pvt. Ltd. in assisting manufacturers in obtaining this certification.

SUMMARY OF IS 3650:1981 – COMBINATION SIDE CUTTING PLIERS

IS 3650 specifies the dimensions, materials, hardness, and performance requirements for combination side-cutting pliers. This standard ensures that pliers used in various applications meet the necessary quality and safety requirements. Below are some key highlights of IS 3650

IS 3650 specifies the dimensions, materials, hardness, and performance requirements for combination side-cutting pliers. This standard ensures that pliers used in various applications meet the necessary quality and safety requirements. Below are some key highlights of IS 3650

Material and Hardness: The body and cutting edges of the pliers must meet specific hardness requirements. The body, especially around the gripping surfaces, must have a hardness between 350 to 510 HV, while the cutting edges must be harder, ranging from 510 to 700 HV (50 to 60 HRC). This ensures that the tool is durable and can withstand high-pressure tasks without deformation(IS 3650).

Dimensions: The standard specifies the dimensions of pliers, including length, jaw thickness, and handle size. Pliers are manufactured in nominal sizes ranging from 160 mm to 250 mm. The cutting angle of the side cutters should range between 90° and 120°, ensuring precision during operation(IS 3650).

Insulated Handles: IS 3650 includes provisions for pliers with insulated handles, commonly used in electrical applications. These handles must be made from materials like PVC, which are securely adhered to the handles to prevent splintering or damage. The insulation must pass electrical safety tests as outlined in IS 2615.

Performance Tests: The pliers must pass several performance tests to ensure their reliability:

Cutting Test: Pliers must demonstrate effective cutting ability for both hard and soft materials.

Tube Gripping Test: The gripping surfaces must securely hold tubes without slipping or damaging the material.

Shock and Torsion Tests: Pliers are subjected to shock and torsion tests to assess their resilience under impact and twisting forces(IS 3650).

Handle Load Test: The handles are tested for their ability to withstand force without permanent deformation, ensuring the tool can endure high-pressure applications(IS 3650).

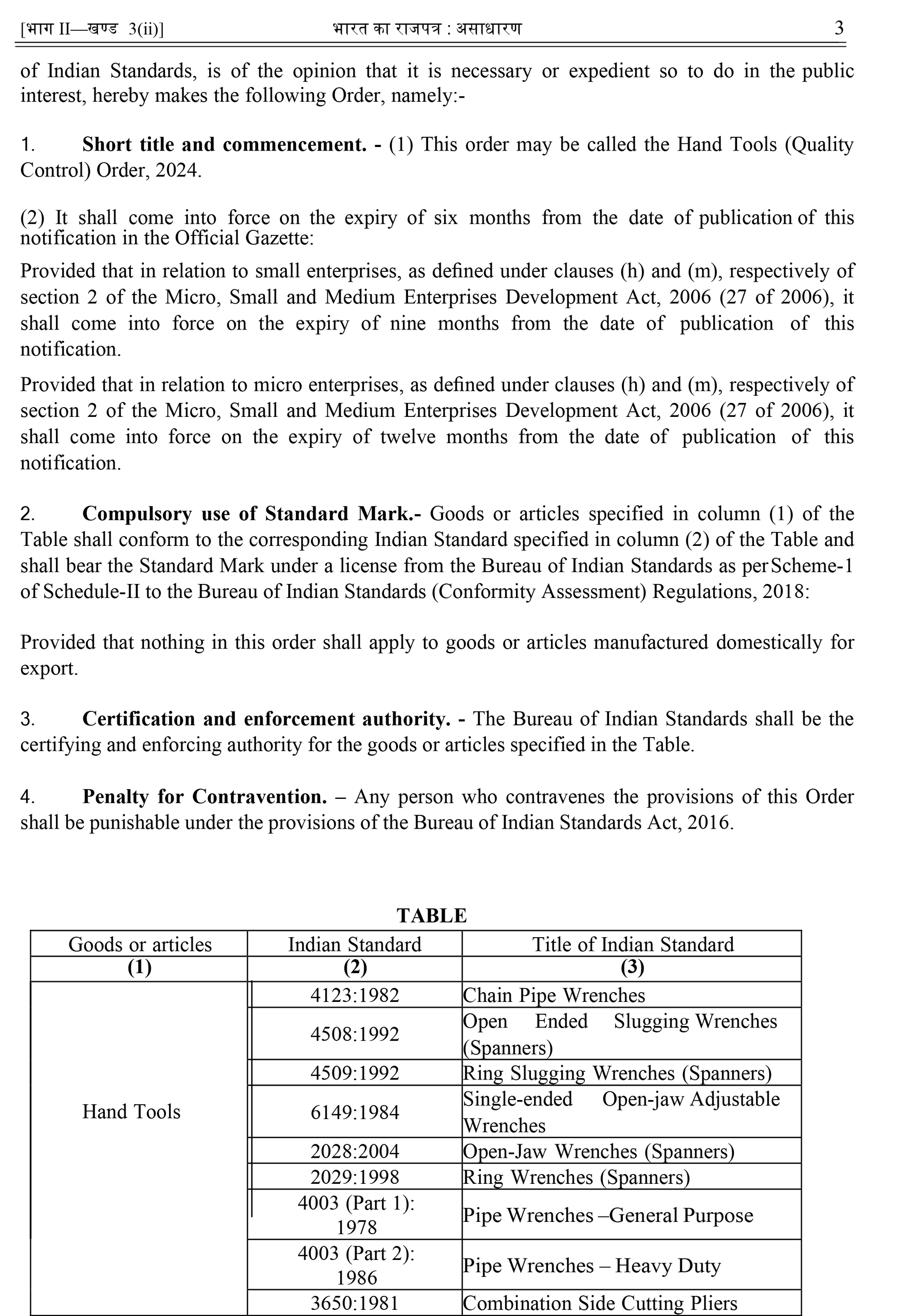

QUALITY CONTROL ORDER AND TECHNICAL REGULATION

The Indian government has mandated BIS certification for all Combination Side Cutting Pliers, whether domestically produced or imported, to ensure compliance with IS 3650. This regulation aims to uphold safety and quality standards across the board, making certification essential for manufacturers to market their tools in India.

BIS CERTIFICATION FOR COMBINATION SIDE CUTTING PLIERS AS PER IS 3650

BIS offers a comprehensive certification scheme for Combination Side Cutting Pliers, requiring manufacturers to undergo rigorous evaluation to demonstrate their compliance with IS 3650. Achieving this certification not only guarantees a high-quality product but also boosts market credibility, enhancing the manufacturer’s competitiveness.

OMEGA QMS PVT. LTD.: YOUR PARTNER IN BIS CERTIFICATION

Omega QMS Pvt. Ltd. specializes in guiding manufacturers through the often complex BIS certification process. Their comprehensive support includes:

- Application Submission: Assisting manufacturers in the precise preparation and submission of BIS certification applications.

- Factory Inspection Preparation: Helping set up essential quality control processes to ensure a smooth BIS inspection.

- Sample Testing Coordination: Managing the submission of product samples to BIS-authorized labs for compliance testing.

- Grant of Licence: Facilitating certification upon successful completion of testing.

For foreign manufacturers, Omega QMS also provides assistance with:

- Nominating Authorized Indian Representatives: Aiding in the appointment of local representatives for BIS.

- Signing Agreements: Guiding manufacturers through necessary agreements with BIS.

- Performance Bank Guarantees: Coordinating the submission of required financial guarantees.

- Ongoing Monitoring: Offering continuous support to maintain compliance through regular audits.

WHY PARTNER WITH OMEGA QMS PVT. LTD.?

Working with Omega QMS provides several significant advantages:

- Expertise: With over 30 years of experience in BIS regulations, their team of experts ensures a smooth and efficient certification process.

- Time and Cost Efficiency: Omega QMS helps reduce both the time and cost involved in securing BIS certification.

- Compliance Assurance: Their meticulous approach minimizes the risk of rejection, ensuring that products meet all necessary standards.

- Ongoing Support: Omega QMS provides continuous assistance to keep manufacturers up to date with evolving regulatory changes.

CONCLUSION AND FINAL THOUGHTS

Combination side-cutting pliers are indispensable tools in various industries, and ensuring their quality is essential for safe and effective operation. By obtaining BIS certification as per IS 3650, manufacturers can guarantee that their pliers meet the required standards for performance, durability, and safety. Omega QMS Pvt. Ltd. plays a key role in guiding manufacturers through the certification process, providing expert support from documentation to factory audits.

For manufacturers, investing in BIS certification is not just a regulatory requirement but a strategic move that enhances product credibility and marketability. With Omega QMS’s assistance, manufacturers can navigate the certification process smoothly, ensuring that their products meet the highest quality standards and are trusted by consumers.

For your Certification needs pls contact:

OMEGA QMS PVT. LTD.

908-909, Hemkunt House, Rajendra Place, New Delhi-110008, India

Email: info@globalomega.com, Phone: 011-41413939(100 lines)

Leave a Reply